Sorting device of automatic logistics conveying line

A technology of logistics automation and sorting device, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of high maintenance cost, high sorting error rate, high noise, etc., to ensure the durability of operation and improve the shaft system. Dynamic, precision-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

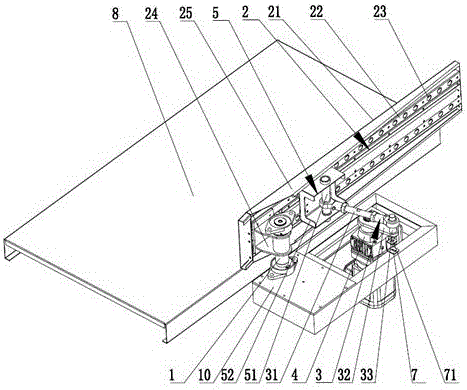

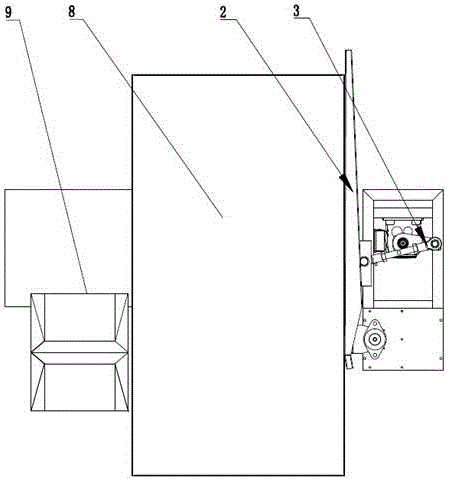

[0024] A kind of sorting device of logistics automatic conveying line disclosed by the present invention, as attached figure 1 As shown, it includes a base plate 10, and the basic shape of the base plate 10 can be various feasible structures. In this embodiment, the base plate 10 is preferably a cuboid as a whole, which includes a support portion and a hollow portion. The support of the base plate 1 A rotating shaft 1 is detachably fixed on the upper part, and the sorting device also includes a lightweight swing arm 2 that rotates around the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com