Unmanned carrying trolley

A technology for transporting trolleys and car bodies, which is applied to lifting devices, lifting frames, etc., can solve the problems of trolley derailment, skidding, accidents, etc., and achieves the effect of compact structure, stable lifting process and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

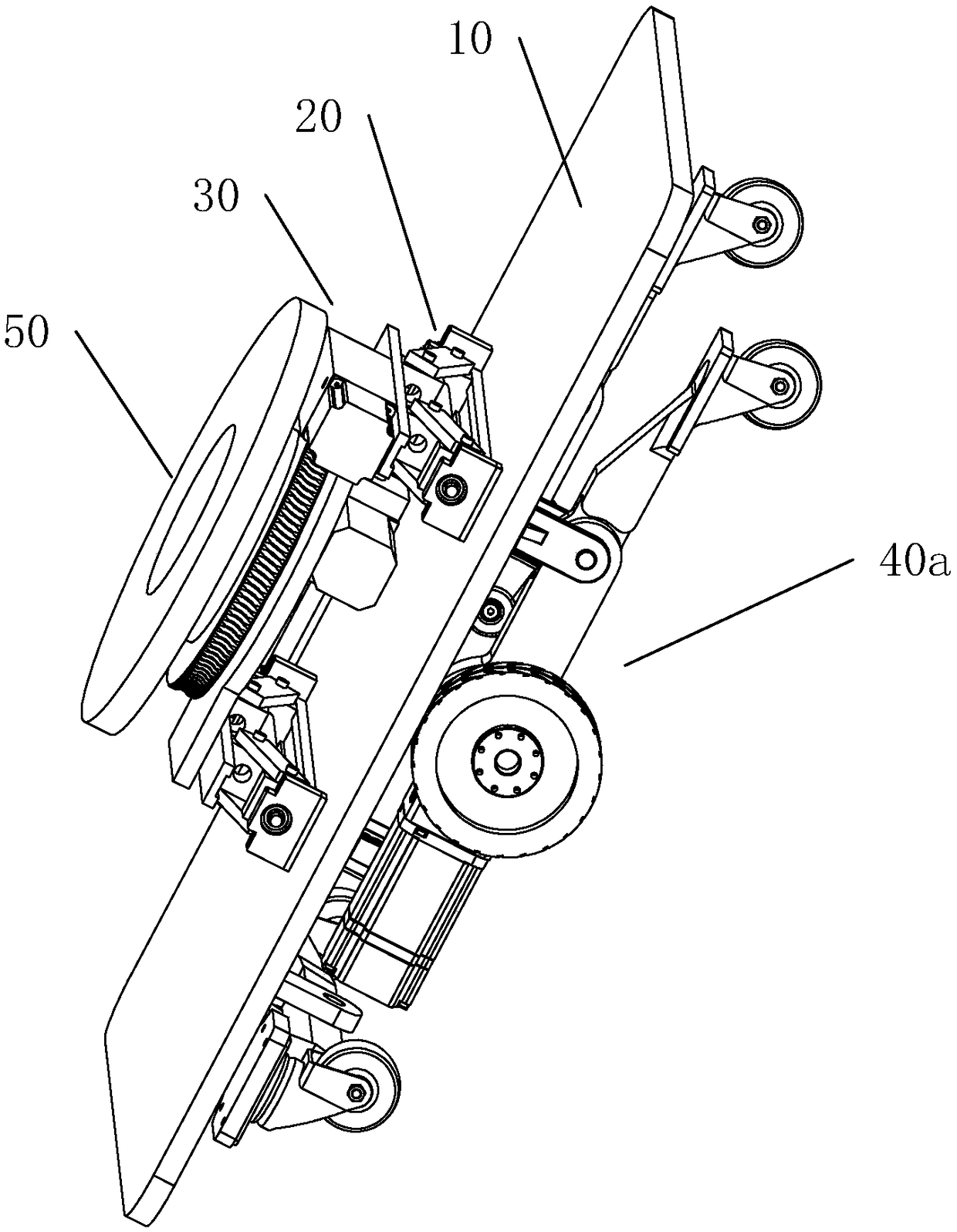

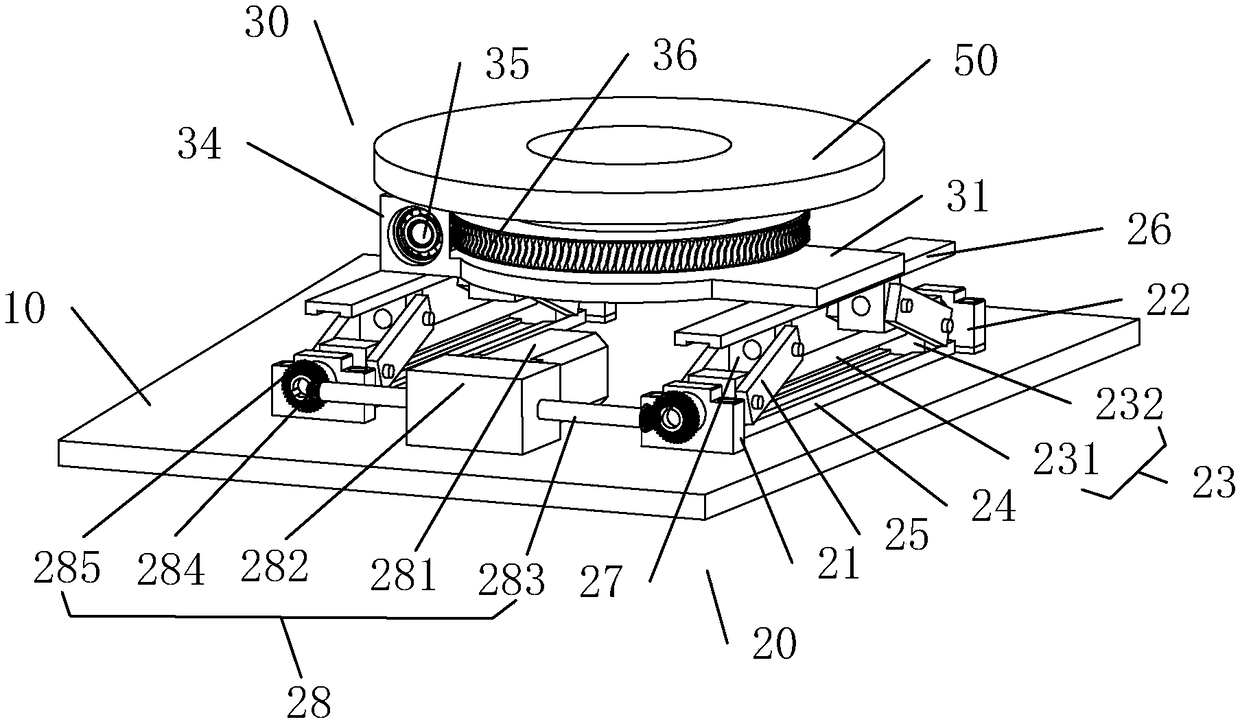

[0035] Such as Figure 1 to Figure 8 As shown, an unmanned transport trolley includes a body 10 , two jacking mechanisms 20 arranged parallel to the upper end of the body 10 , and a driving mechanism 40 a arranged at the bottom of the body 10 .

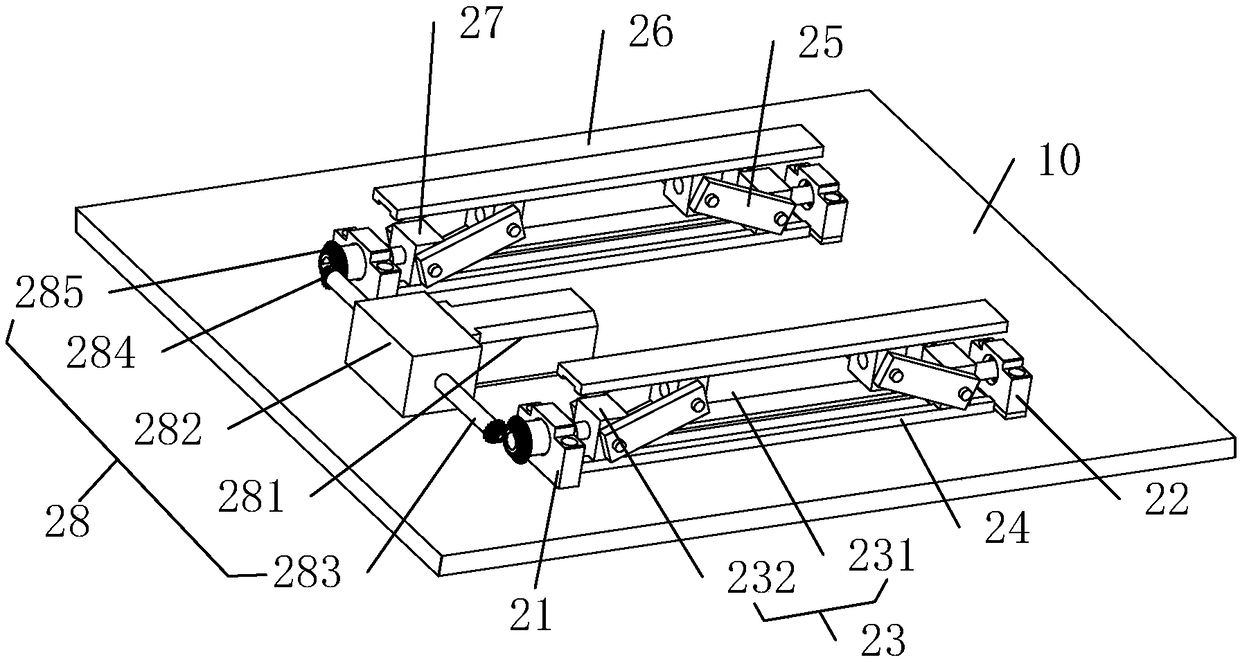

[0036] Specifically, the jacking mechanism 20 includes a fixed base 21 fixed on the installation base 10, a support base 22 fixed on the installation base 10 and opposite to the fixed base 21, and the two ends are respectively rotated on the fixed base 21 and the support base 22. The double-ended screw 23 , the power structure 28 for driving the screw 231 to rotate, and the slide rail 24 fixed on the installation base 10 and located on the lower side of the screw 231 . The two threaded seats 232 of the double-ended screw mandrel 23 are all slidably located on the slide rail 24, and each threaded seat 232 is hinged with a connector 25; also includes a bearing plate 26; the other ends of the two connectors 25 are respectively hinged on T...

Embodiment 2

[0049] combine Figure 2 to Figure 5 and Figure 8 ~ Figure 13 As shown, compared with Embodiment 1, this embodiment provides another driving mechanism 40b, and other structures are the same as Embodiment 1.

[0050] Concretely, two groups of drive mechanism 40b are symmetrically arranged on the driving unit 41b in the middle of the bottom of the vehicle body 10 with the central axis of the vehicle body, the driven unit 42b is arranged on the front side of the bottom of the vehicle body 10, and the rear driven unit is arranged on the rear side of the bottom of the vehicle body 10. Unit 43b.

[0051] The driven unit 42b includes a front mounting seat 42b1 fixed on the lower end surface of the object-bearing platform, a rotating shaft bracket 42b2 hinged to the front mounting seat 42b1, a front driven wheel bracket 42b3 rotatably connected to the moving end of the rotating shaft bracket 42b2 in the middle, and two The front driven wheel 42b4 is located at both ends of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com