Tracking and monitoring system and method of stacking robot based on machine vision

A palletizing robot and machine vision technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as the need to improve reliability and stability, and the limited intelligence of palletizing robots, saving labor costs and time. Cost, flexibility enhancement, clear logic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

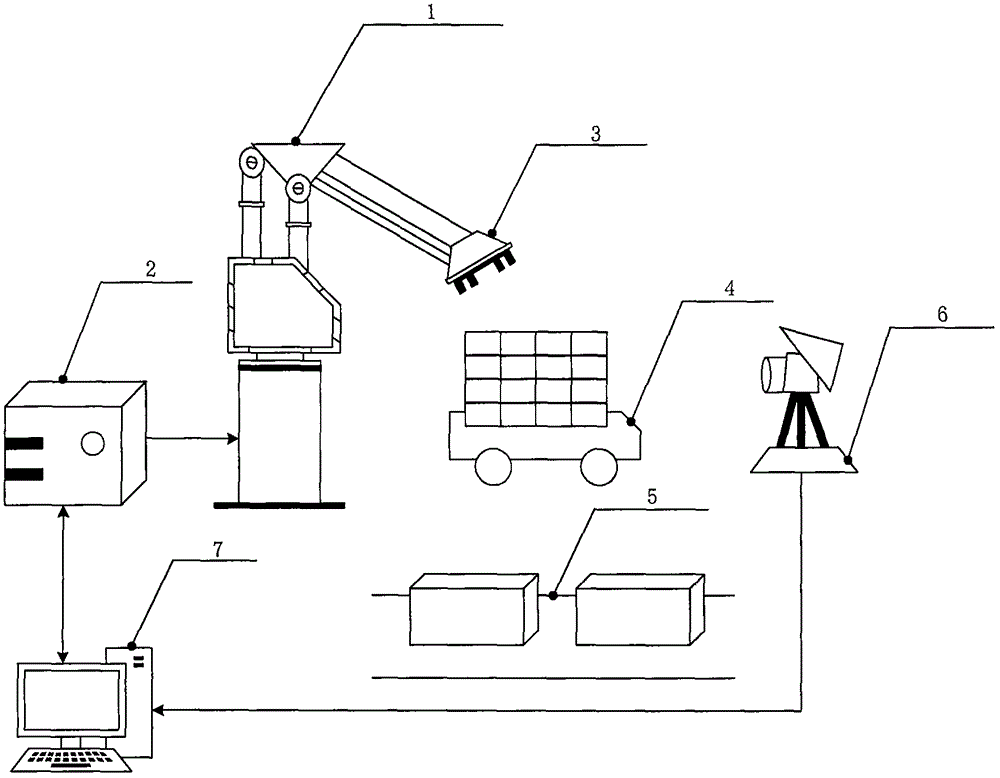

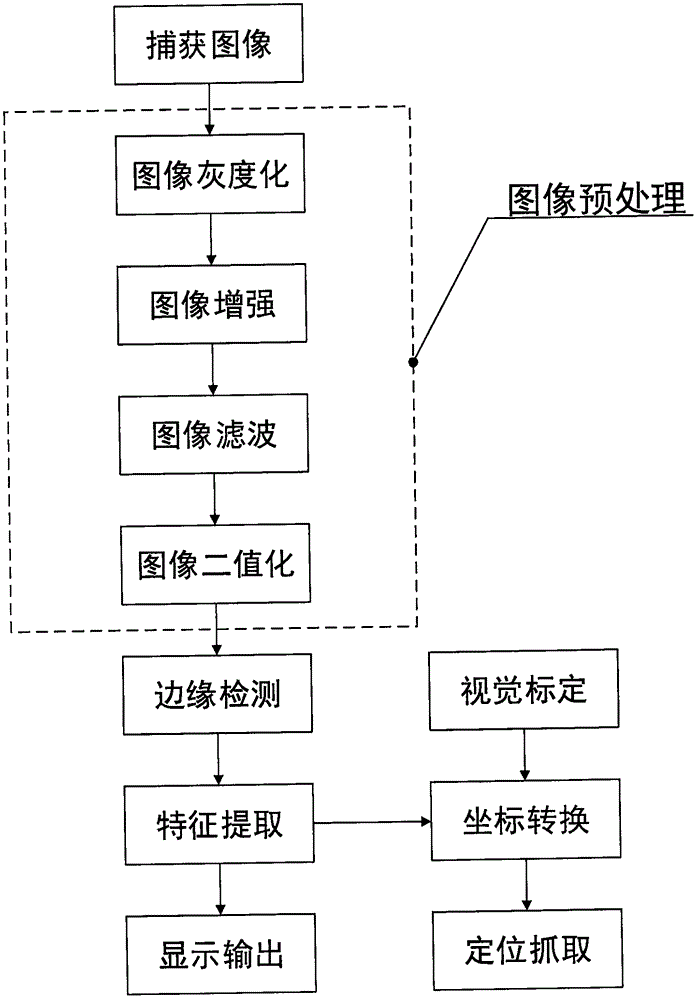

[0018] Such as figure 1 As shown in the schematic diagram of the structure, a palletizing robot tracking and monitoring system and method based on machine vision includes a palletizing robot body (1) and its control cabinet (2), the palletizing robot is connected to the control cabinet by communication, and the vacuum suction cup (3) Installed at the end of the palletizing robot, the palletizing robot takes the goods from the pallet of the conveyor belt (5), and stacks them to the loading plane of the AGV (4) in sequence according to the predetermined trajectory. When the weight of the palletized goods reaches the predetermined When the limit is reached, start to track the goods to the warehouse for sorting, and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com