Shuttle shelf type flue-cured tobacco lamina formula warehouse logistics automation system

A technology of logistics automation and shuttle racking, which is applied in the dense storage equipment and storage field of cigarette packs, to achieve the effect of improving the production capacity of inbound and outbound warehouses, stable structure, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

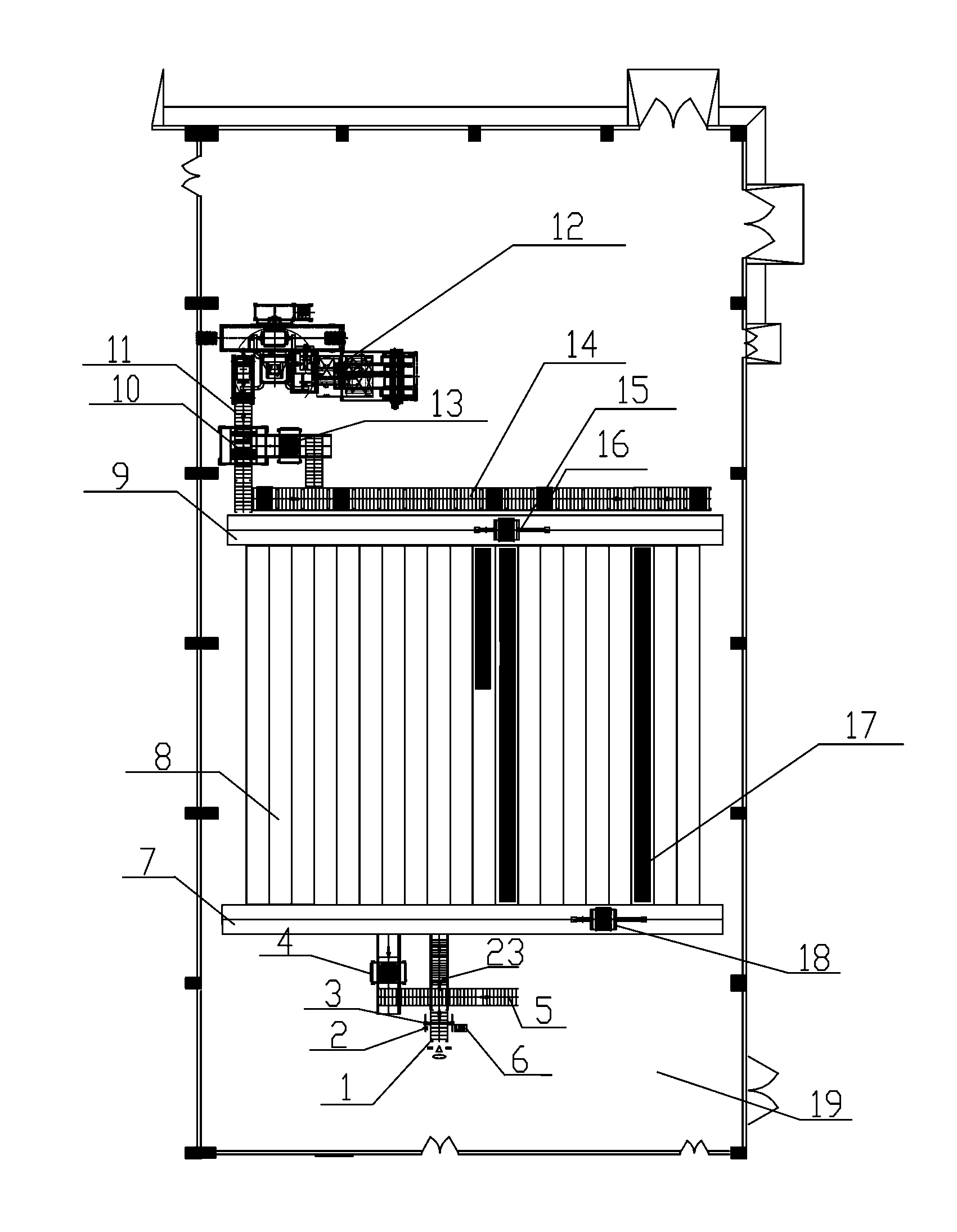

[0016] At present, the front end of the production line of the tobacco industry enterprise's shredding workshop is the feeding area 19, and the front-end process of cigarette production is tobacco leaf preparation, batching preparation, etc. Tobacco leaves are prepared according to the following process: the production management department first releases the feeding formula of this stage according to the production plan, and the logistics department organizes the transportation and collection of laminar packs of various grades in the formula from different tobacco leaf alcoholization warehouses to the feeding area 19 for temporary storage, and finally According to the received production plan, the shredded tobacco bales are placed in the bale feeding order sorting buffer area according to the feeding order of the formula lamina bales according to the received production plan, and the preparation of the tobacco leaves is completed in this way.

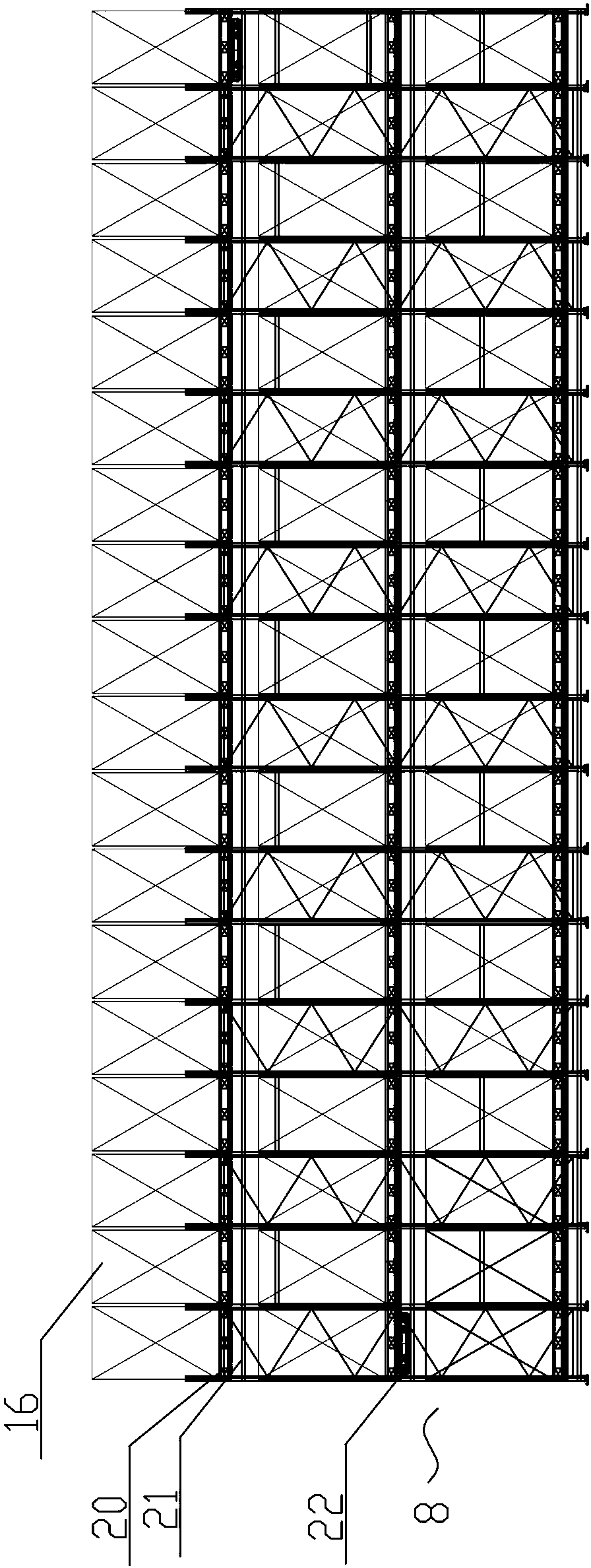

[0017] Such as figure 1 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com