Control system and method for secondary precise positioning of AGV

A control system and precise positioning technology, applied in control/regulation system, two-dimensional position/channel control, vehicle position/route/height control, etc., can solve the problems of low positioning accuracy and failure to meet positioning requirements, and achieve guaranteed Efficiency and positioning accuracy, the effect of automatic adjustment of the travel route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

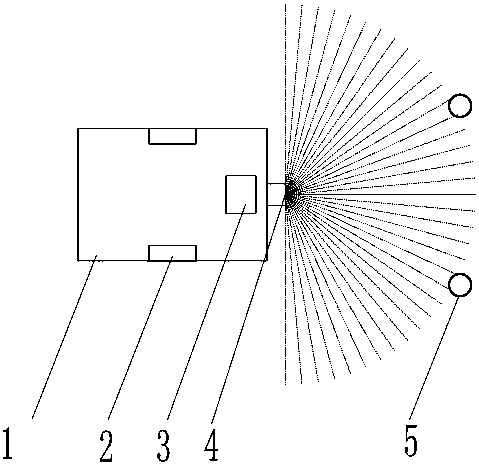

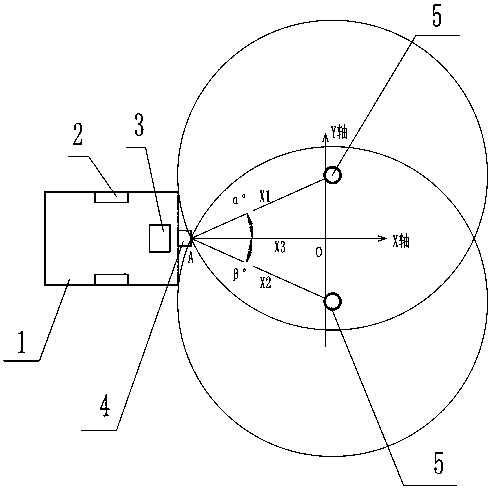

[0036] Example 1, such as figure 1 Shown: The system includes an AGV trolley. The mechanical structure of the trolley is not much different from the existing technology. It has a walking structure and a driving device 2. Specifically, it includes two driving wheels, one on the left and one on the right. 1 on both sides. In this case, each driving wheel is controlled by a driving motor independently, and the posture of the vehicle body 1 can be adjusted according to the left and right differential speed.

[0037] The car body 1 is connected with a scanning device 4, in this embodiment, as figure 1 As shown, the scanning device 4 can be a laser head, which performs laser scanning within a range of 360° or 180° in front, and can initially set a value X0, which is the identified scanning radius for detecting the auxiliary positioning device 5 .

[0038] In this example, if figure 1 As shown, the auxiliary positioning device 5 is a reflector, and there are at least two, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com