led car headlight module

A technology of automobile headlights and modules, which is applied in the direction of lighting devices, fixed lighting devices, lighting and heating equipment, etc., can solve the problems of poor heat dissipation, weak lighting, low light efficiency, etc., and achieve simple and reasonable structural design and easy use Easy operation and high light utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

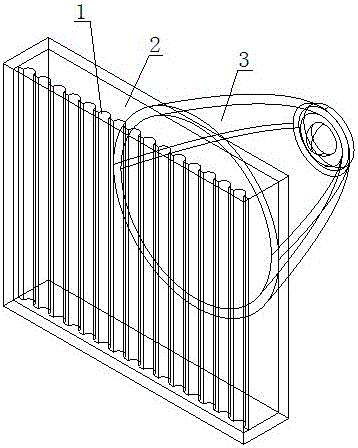

[0024] like figure 1 As shown, as the first preferred embodiment, the LED automotive headlight module includes a light-concentrating reflector cup 3, a sealing groove 2 and an optical diffusion sheet 1, and the front end of the light-condensing reflector cup 3 is provided with the sealing groove 2 , the optical diffusion sheet 1 is disposed in the sealing groove 2, wherein the optical diffusion sheet 1 is fixed in the sealing groove 2 by glue.

[0025] In the above-mentioned embodiment 1, after the light of the LED lamp is converged by the light-concentrating reflector cup 3 , it is horizontally diffused by the optical diffusion sheet 1 to be the low-beam light. The structure is simple, and the light utilization rate of the light-emitting unit is high.

Embodiment 2

[0027] As the second preferred embodiment, the rest is the same as that of Embodiment 1, the difference is that a filling liquid is also arranged in the sealing groove 2, the filling liquid is a transparent filling liquid, and the refractive index of the filling liquid is the same as that of the filling liquid. The optical diffusion sheet 1 has the same refractive index.

[0028] In the above-mentioned embodiment 2, after the light of the LED lamp is converged by the light-concentrating reflector cup 3, it is combined with the filling liquid and the optical diffusion sheet 1 to provide high beam lighting. The structure is simple, and the refractive index of the filling liquid and the optical diffusion sheet 1 are used to Consistent features to achieve high beam lighting with LED lights.

Embodiment 3

[0030] As a third preferred embodiment, the rest is the same as Embodiment 1 or 2, except that it also includes a storage tank, which is connected to the sealing tank 2 through a pipe, and the optical diffusion sheet 1 is fixed to the sealing tank 2 by screws. In the sealing groove 2, the sealing groove 2 is cylindrical.

[0031] In the above-mentioned embodiment 3, the switching between the high beam and the low beam is realized by moving the filling liquid from the sealing tank to the storage tank, the operation is convenient, and the structural design is simple and reasonable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com