Membrane bioreactor wastewater treatment equipment

A membrane bioreactor, wastewater treatment technology, applied in biological water/sewage treatment, water/sewage treatment equipment, water/sewage treatment, etc., can solve the problem of reducing the effect of sewage treatment, failure of aeration device, blockage of aeration holes, etc. problem, to achieve the effect of good effect, automatic flushing switching, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

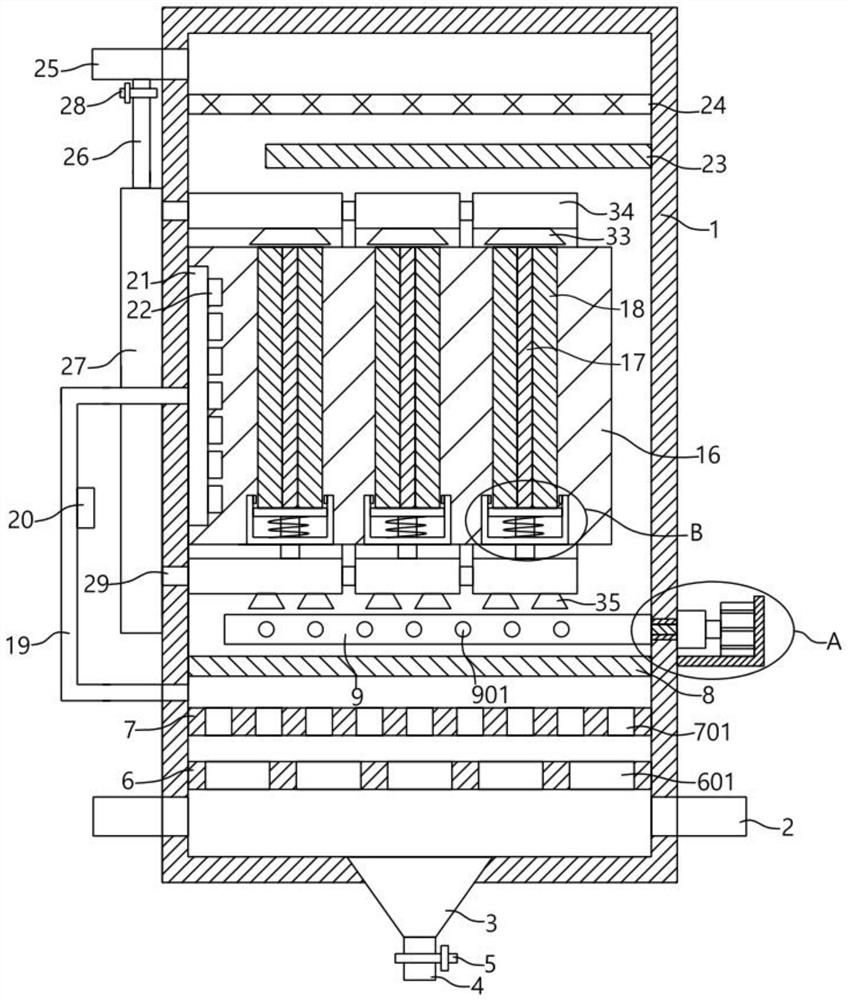

[0030] A membrane bioreactor wastewater treatment equipment includes a treatment box 1, and a water inlet pipe 2 is communicated with the lower end side wall of the treatment box 1. Waste water is introduced in different directions, and the inner cavity of the treatment box 1 is sequentially fixed with a coarse grid 6, a fine grid 7 and a partition 8 from bottom to top. There are fine through holes 701, and the diameter of the thick through holes 601 is larger than that of the fine through holes 701. Therefore, when the waste water passes through the coarse grid 6 and the fine grid 7 in turn, preliminary filtration can be achieved, and then large impurities are intercepted. 8 is a fully enclosed type, so that the inner cavity of the treatment box 1 can be divided into two parts, an aeration pipe 9 is arranged above the partition plate 8, and a plurality of aeration holes 901 are opened on the aeration pipe 9, and the aeration holes 901 is provided with an anti-blocking net, th...

Embodiment 2

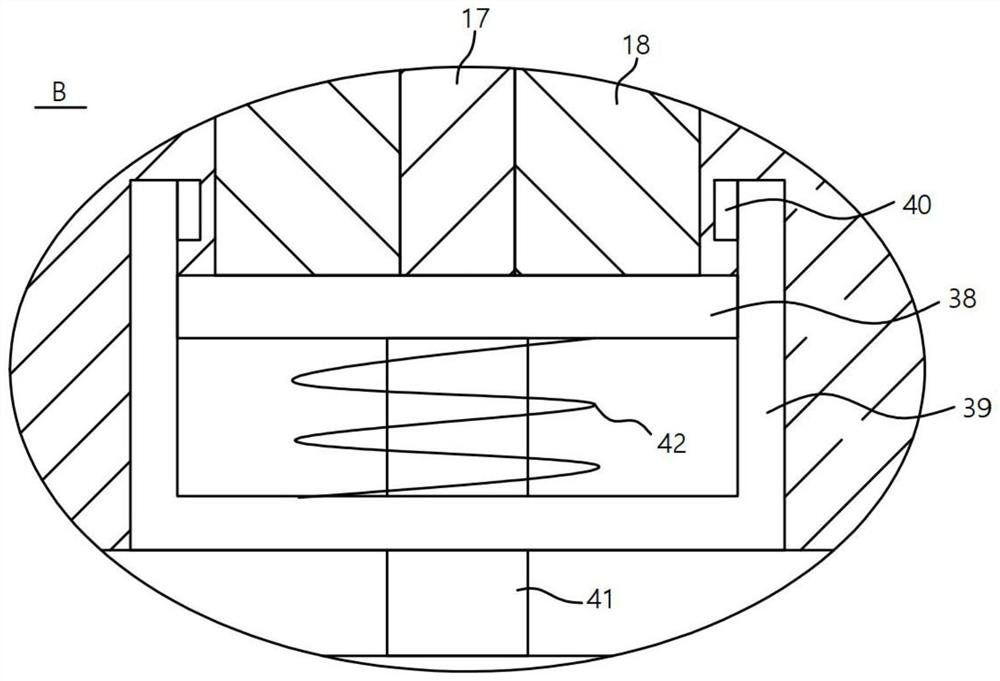

[0034] A membrane bioreactor wastewater treatment equipment includes a treatment box 1, a water inlet pipe 2 is communicated with the lower end side wall of the treatment box 1, a sewage discharge funnel 3 is communicated with the bottom of the treatment box 1, and a sewage discharge funnel 3 is fixedly arranged below. The sewage pipe 4, the sewage pipe 4 is provided with a sewage valve 5, and the opening and closing of the sewage valve 5 can be used to control whether the sewage pipe 4 is opened or not. After a period of use, the large dirt in the wastewater will be intercepted and precipitated. In the sewage funnel 3, the sewage valve 5 can be opened regularly, and the sewage can be discharged through the sewage pipe 4. The inner cavity of the treatment box 1 is fixedly arranged with a coarse grid 6, a fine grid 7 and a The partition plate 8, the coarse grid 6 is provided with a coarse through hole 601, and the fine grid 7 is provided with a fine through hole 701. The diamete...

Embodiment 3

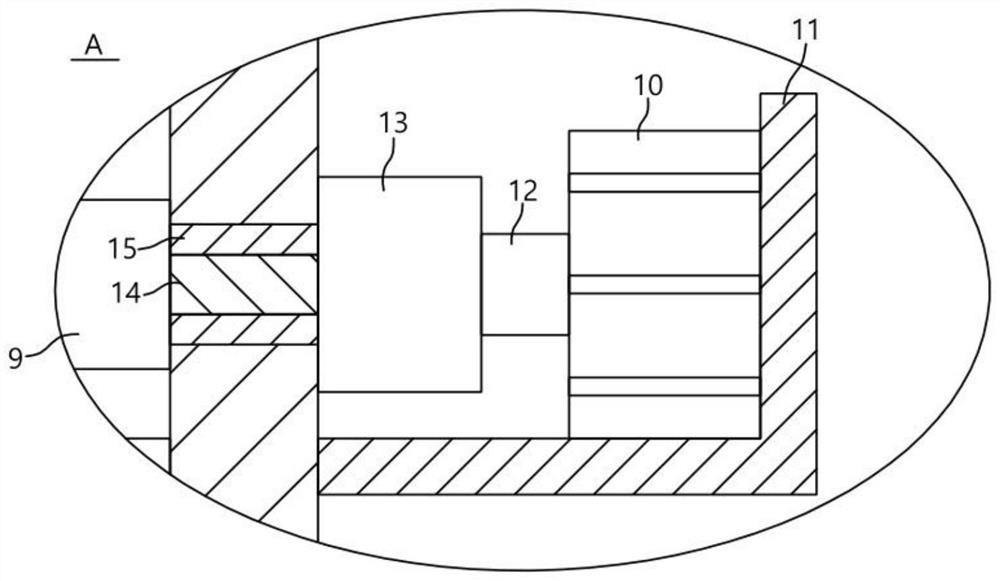

[0038] On the basis of the above-mentioned first and second embodiments, this embodiment further discloses and defines the specific structure of the power device. Specifically, the power device includes a rotating electrical machine 10 , and the rotating electrical machine 10 is fixedly arranged on the support plate 11 . , the support plate 11 is fixedly arranged on the outer wall of the processing box 1. In this embodiment, the support plate 11 is L-shaped, which is convenient for placing the rotary motor 10. The output shaft of the rotary motor 10 is fixedly provided with a rotary shaft 12, and the rotary shaft 12 is far away from the rotation. One end of the motor 10 is fixed on the air pump 13, so the rotating motor 10 in the starting state can drive the air pump 13 to rotate through the rotating shaft 12, and the air pump 13 is communicated with the aeration pipe 9 through the conveying air rod 14. Therefore, the air pump 13 can pass through the conveying air rod. 14 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com