Lifting-up weighing sorting system used for logistics automatic production line and sorting method thereof

A logistics automation and sorting system technology, applied in the field of transportation and sorting, can solve the problems of low efficiency and high logistics costs, and achieve the effects of reasonable and convenient operation, simple and reasonable structural design, and reasonable and accurate weighing and sorting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

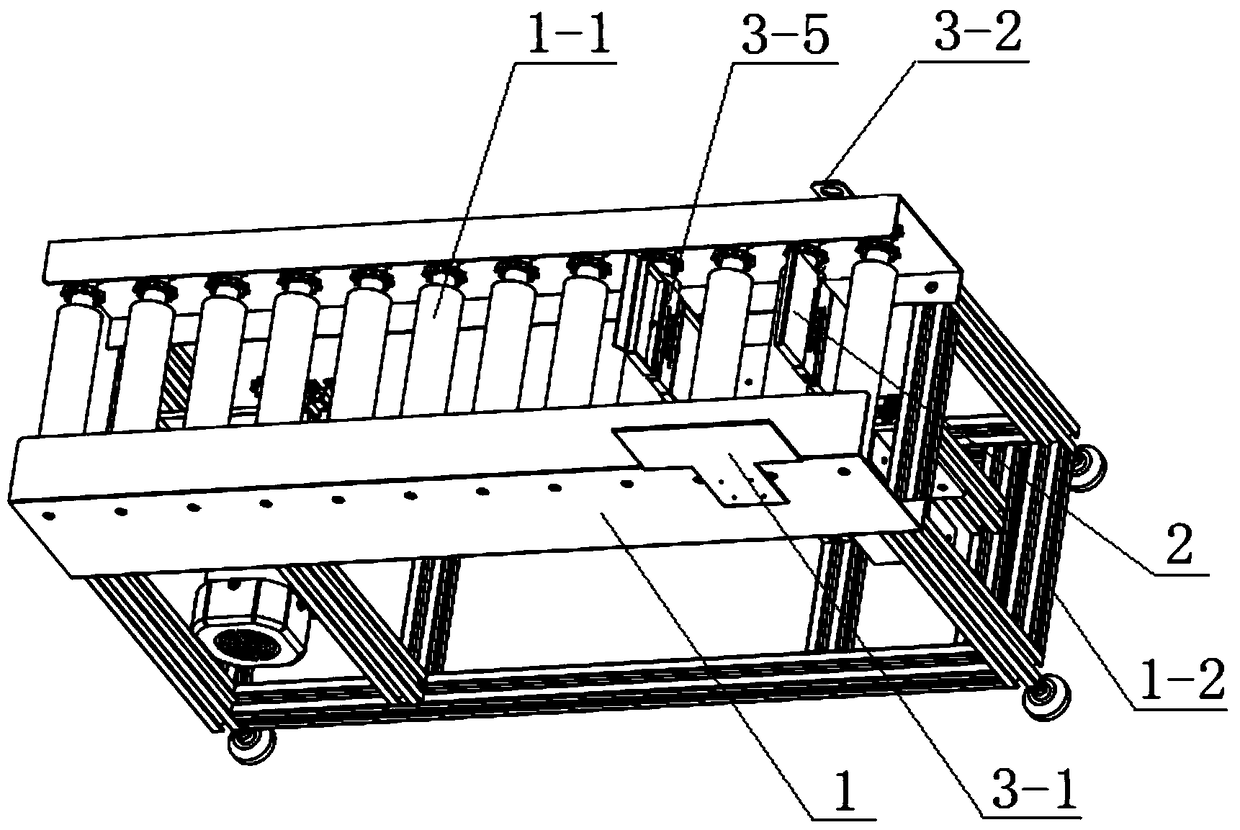

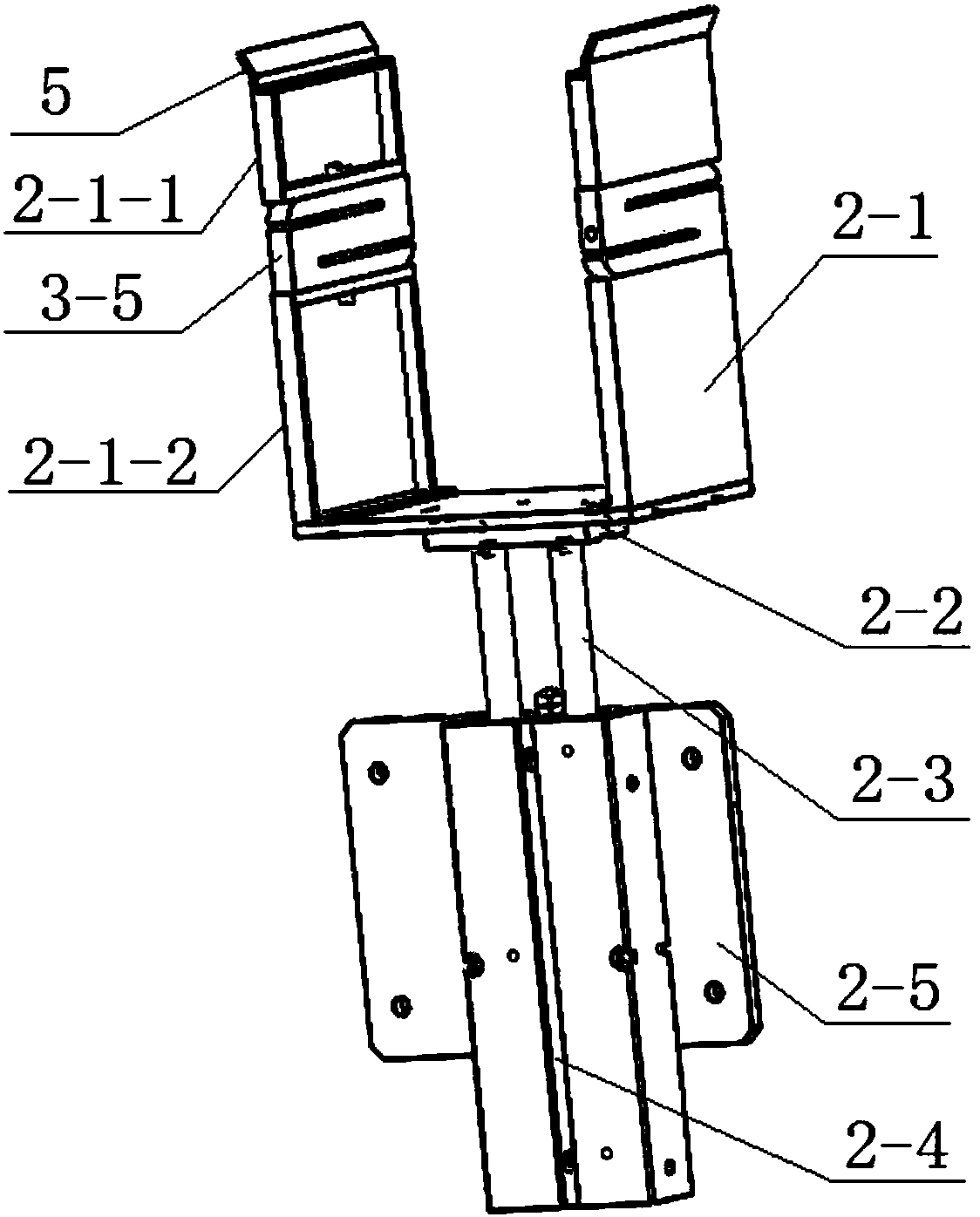

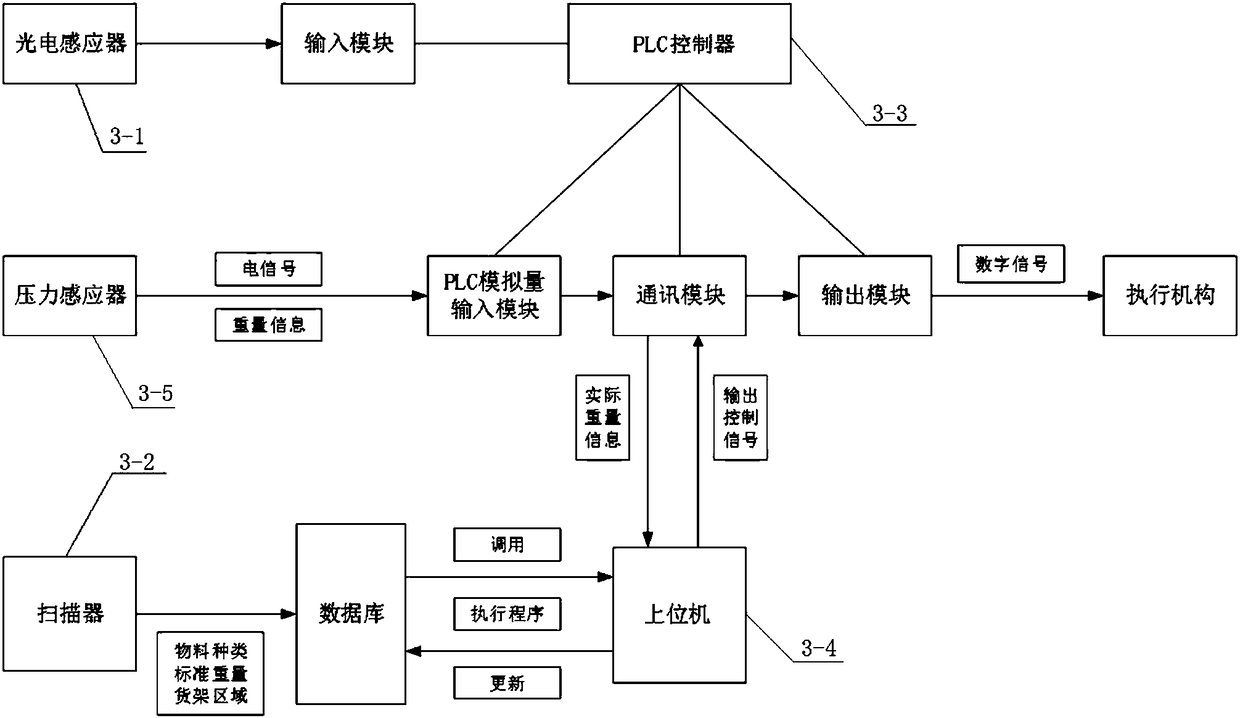

[0029] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Describe this embodiment. This embodiment includes a roller conveyor 1, a jacking device 2 and a control assembly. Rod 2-1, two supporting rods 2-1 are vertically arranged side by side in the gap between the rollers 1-1 in the roller conveyor 1, and the two ends of the supporting base plate 2-2 are respectively connected to the bottoms of the two supporting rods 2-1. connection, the top of the guide shaft assembly 2-3 is connected to the bottom of the support base plate 2-2, the bottom of the guide shaft assembly 2-3 is set in the cylinder 2-4 and the two are slidably fitted, and the cylinder 2-4 is set in the roller conveying On the frame 1-2 of the machine 1; the control assembly includes a photoelectric sensor 3-1, a scanner 3-2, a PLC controller 3-3, an upper computer 3-4 and two pressure sensors 3-5, and each support rod 2-1 is provided with a pressure sensor 3-5, the photoelectric senso...

specific Embodiment approach 2

[0035] Specific embodiment two: present embodiment is the further limitation of specific embodiment one, is provided with switchboard 3-6 between PLC controller 3-3 and host computer 3-4, and PLC controller 3-3 passes switchboard and host computer 3 -4 electrical connections.

[0036] The analog quantity input module of PLC controller 3-3 among the present invention converts electric signal into digital signal, passes switchboard 3-6 to host computer 3-4, and host computer 3-4 is by transferring database, and PLC controller The information transmitted by 3-3 is compared to obtain the weight difference of the goods to determine whether the goods are in a full box weight state, and send an output command to the PLC controller 3-3, so that it can control the actuator to perform corresponding operations. In order to reasonably classify the goods and store them in different regions.

specific Embodiment approach 3

[0037] Specific embodiment three: This embodiment is a further limitation of specific embodiment two, the photoelectric sensor 3-1 transmits the first electrical signal to the PLC controller 3-3, and each pressure sensor 3-5 transmits the second electrical signal to The switch 3-6 and the scanner 3-2 transmit the third electrical signal to the upper computer 3-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com