High-precision parking AGV vehicle fork-taking device and parking method thereof

A high-precision, vehicle-based technology, applied in transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems that cannot be effectively realized, and achieve the effects of improving accuracy, reducing transformation costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

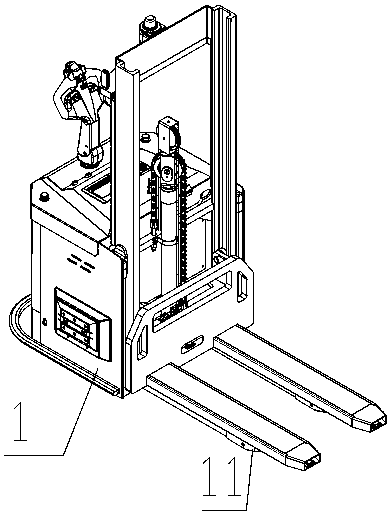

[0033] Example 1, such as figure 1 and figure 2 As shown: it includes an AGV trolley. The trolley is structurally the same as the existing trolley. It also includes a transmission walking structure, such as a walking wheel, including a leg 11 and a fork for picking up goods. The fork has a lifting device, which can be lifted and lowered in the vertical direction to adjust its height position.

[0034] On the basis of the existing structure, it is necessary to install sensor components on the car body 1 of the AGV trolley. Specifically, there are at least three sensor components, which are two distance sensors 32 and one position detection sensor 31 respectively. Two of the distance sensors 32 can be mounted on the legs 11 .

[0035] Correspondingly, this technical solution needs to deploy the freight environment. There are shelves in the storage environment, pallets are stacked on the shelves, goods are placed on the pallets, and there are gaps in the pallets. The forks of ...

Embodiment 2

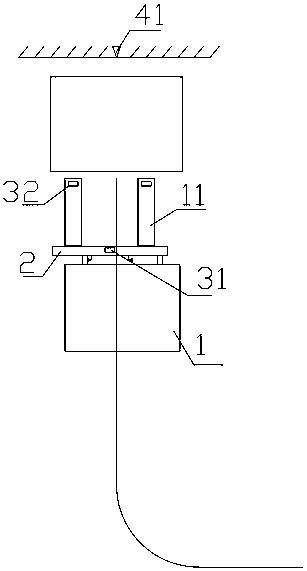

[0043]Embodiment 2 is different from Embodiment 1 in that the distance sensor 32 is installed on the pallet fork. When installed on the pallet fork, since the pallet fork is different from the truck legs 11, there is lifting during the stacking process. Therefore, in order to cooperate with the distance sensor 32 , corresponding baffles 41 must be provided at different height positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com