Automated code complementing process for uncoded package tobacco

A coding and complementing technology, which is applied in the field of automatic code complementing technology, can solve problems such as automatic code complementing technology for uncoded parts, so as to promote production efficiency and economic benefits, and eliminate errors and unnecessary loss, increase the effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

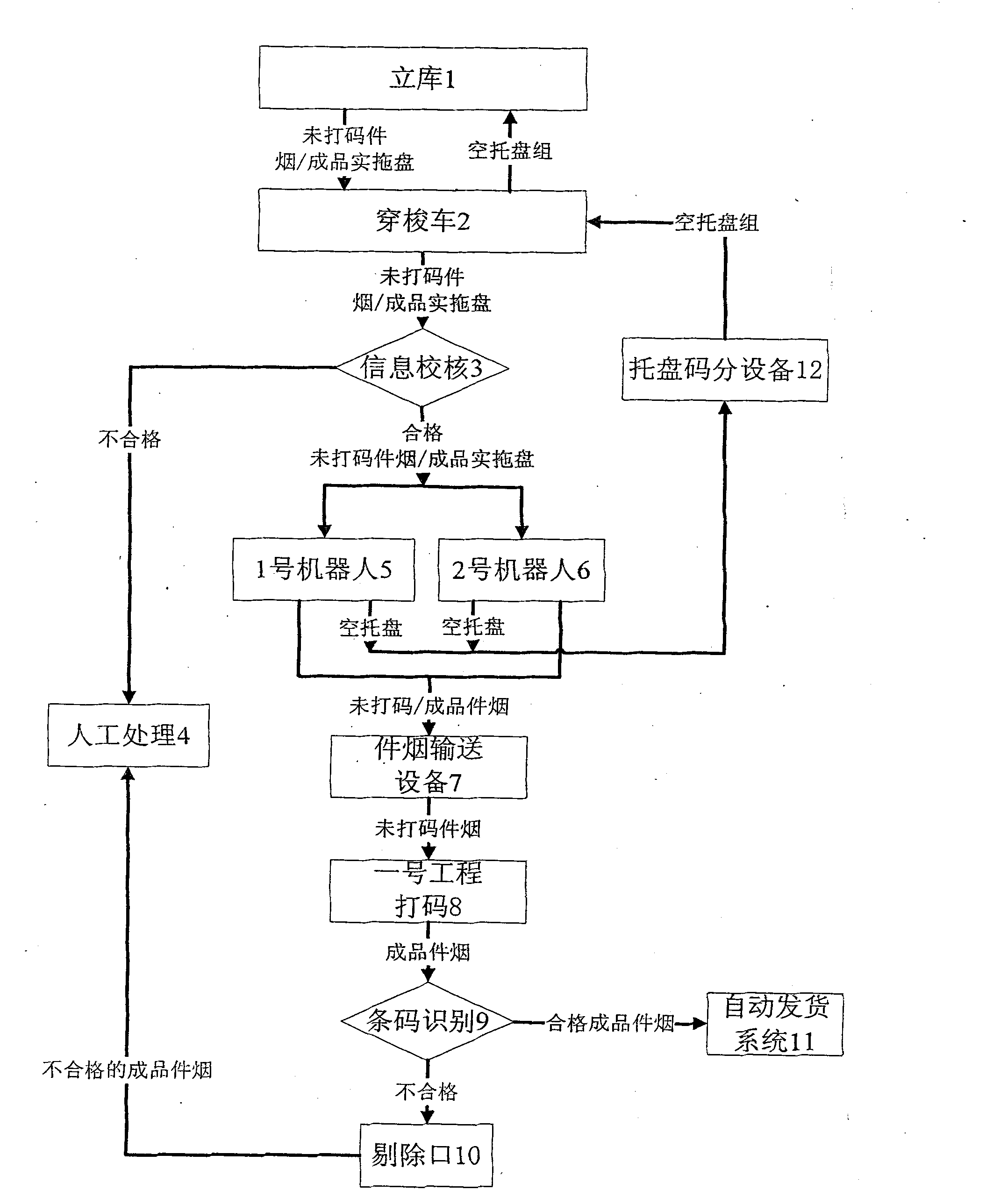

[0017] Example 1: Automated code supplementation for uncoded cigarettes that need to be shipped directly

[0018] Such as figure 1 As shown, the uncoded cigarette trays are transferred from the vertical warehouse 1, transported by the shuttle car 2, and the pallet information is checked 3 during the transportation process, and the unqualified cigarette trays are sent to manual processing 4 by The operator handles it. Qualified solid cigarette trays are directly sent to the unstacking stations of No. 1 robot 5 and No. 2 robot 6 for unstacking. The number of robots used can be flexibly determined according to the batch size of the cigarettes. The unstacked cigarettes are automatically conveyed by the cigarette conveying equipment 7, and the No. 1 project is coded 8 on the way to become finished cigarettes. Carry out bar code identification 9 afterwards, carry out manual processing 4 after unqualified piece cigarette is rejected from rejecting port 10, the finished product piec...

Embodiment 2

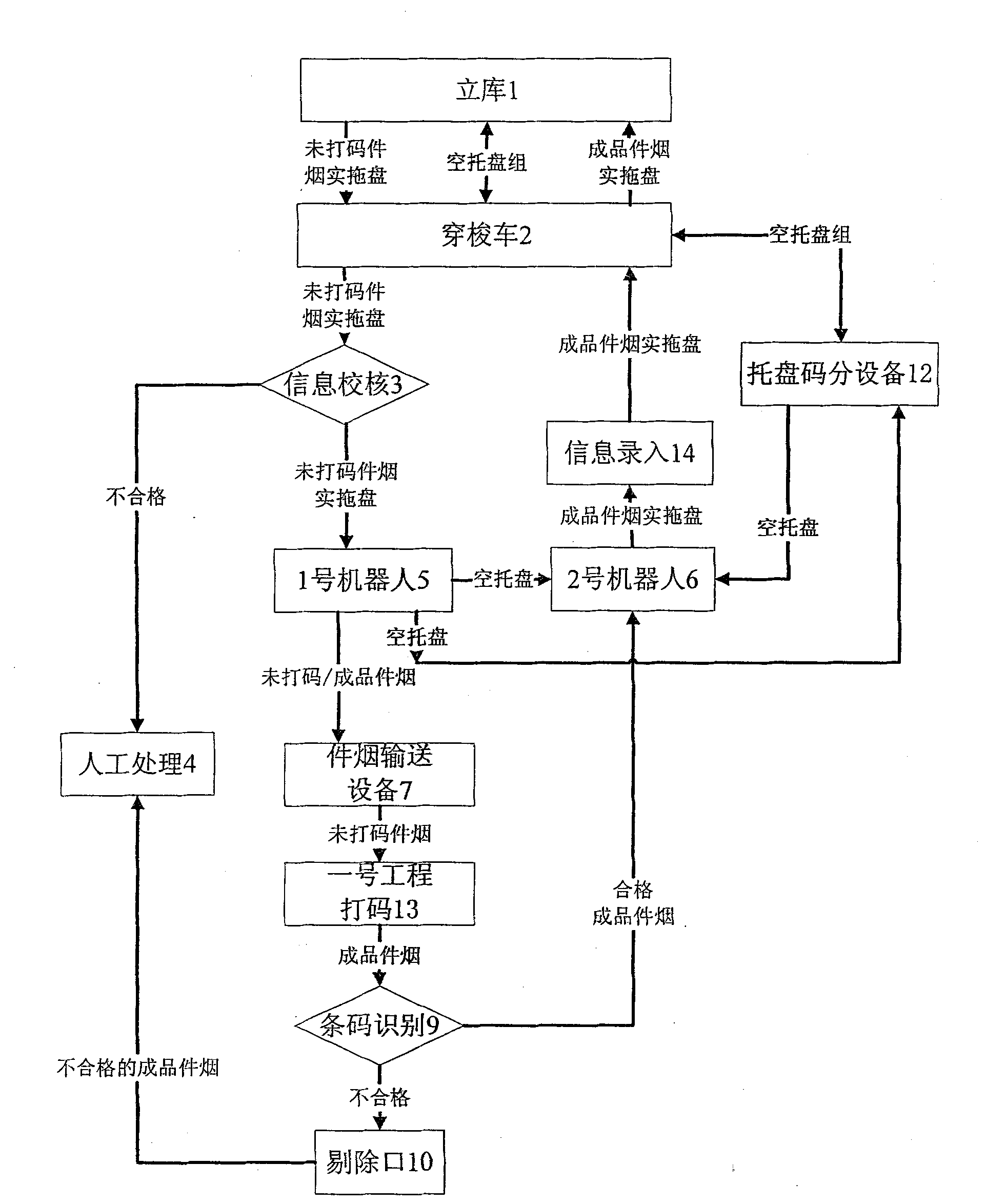

[0020] Example 2: Automated code supplementation for uncoded cigarettes that do not require direct delivery

[0021] Such as figure 2 As shown, the pallet of unmarked cigarettes is transferred from the vertical warehouse 1, transported by the shuttle car 2, and the pallet information check 3 is performed during the transport process. Unqualified pieces of tobacco pallets are sent to manual processing 4 to be processed by operators, and qualified pieces of tobacco pallets are directly sent to the destacking station of No. 1 robot 5 for destacking. The unstacked cigarettes are automatically conveyed by the cigarette conveying equipment 7, and the No. 1 project is coded 13 on the way to become finished cigarettes. Carry out barcode identification 9 afterwards, the unqualified cigarettes are removed from the rejecting port 10 and then manually processed 4, and the finished cigarettes qualified by the barcode identification 9 are transported to the palletizing station of No. 2 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com