Sorting device of logistics automatic conveyor line

A logistics automation and sorting device technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high sorting error rate, high maintenance cost, difficult maintenance and repair, etc., to ensure stability, improve accuracy, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

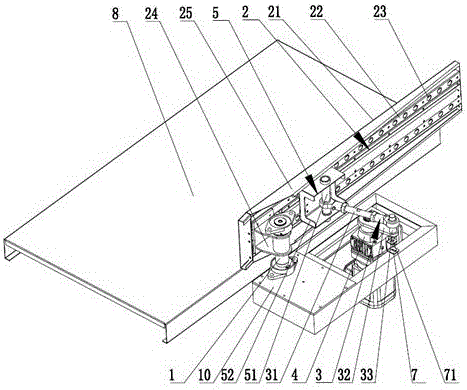

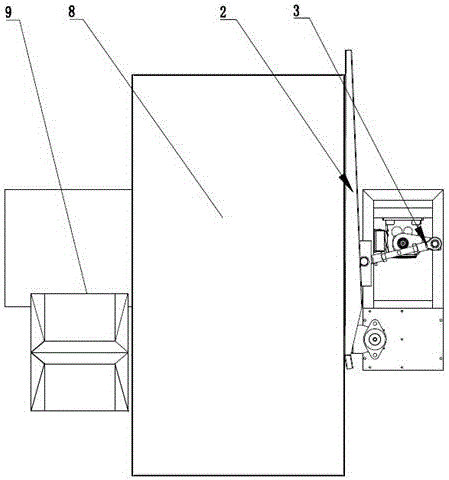

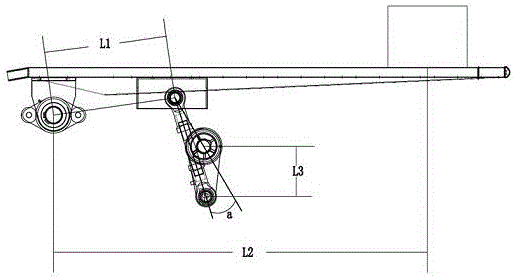

[0031] The sorting device of the logistics automation conveying line disclosed by the present invention, as attached figure 1 As shown, it includes a base plate 10, and the basic shape of the base plate 10 can be various feasible structures. In this embodiment, the base plate 10 is preferably a cuboid as a whole, which includes a support portion and a hollow portion. The support of the base plate 1 A rotating shaft 1 is detachably fixed on the upper part, and the sorting device also includes a lightweight swing arm 2 that rotates around the rotating shaft 1, and the lightweight swing arm 2 includes a push plate 21, and the push plate 21 Various feasible structures and shapes are possible. In this embodiment, the pushing surface of the pushing plate 21 that contacts the article is preferably rectangular.

[0032] The back side of the push plate 21 is provided with side walls 25 with flanging on both sides along the length direction, and at least two parallel reinforcing rods 22...

Embodiment 2

[0047] This embodiment is similar to the overall structure and principle of Embodiment 1, the difference is: as attached Figure 4 And attached Figure 5 As shown, the driving device 4 includes a motor 1, the motor 1 is connected to the driving wheel 42 and drives it to rotate, the driving wheel 42 is connected to the driven wheel 44 through a synchronous belt 43 and rotates synchronously, and the driven wheel 44 is connected to the The crank 32 of the crank linkage mechanism 3 .

[0048] The reason why the structure of this embodiment is adopted is mainly to consider that: during the swinging process of the lightweight swing arm, since the lightweight swing arm 2 may be stuck by flexible objects such as cloth bags, and thus cannot be swung back, the crank linkage mechanism Also just can't continue to run, yet because motor is still in normal running state, at this moment, if the crank in the motor and the crank-link mechanism is directly connected, the power of the motor rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com