Hinge component assembling machine

A technology for assembling machinery and hinge components, which is applied in the direction of assembly machines, workpiece clamping devices, metal processing equipment, etc., and can solve the problems of difficult assembly, low assembly efficiency, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

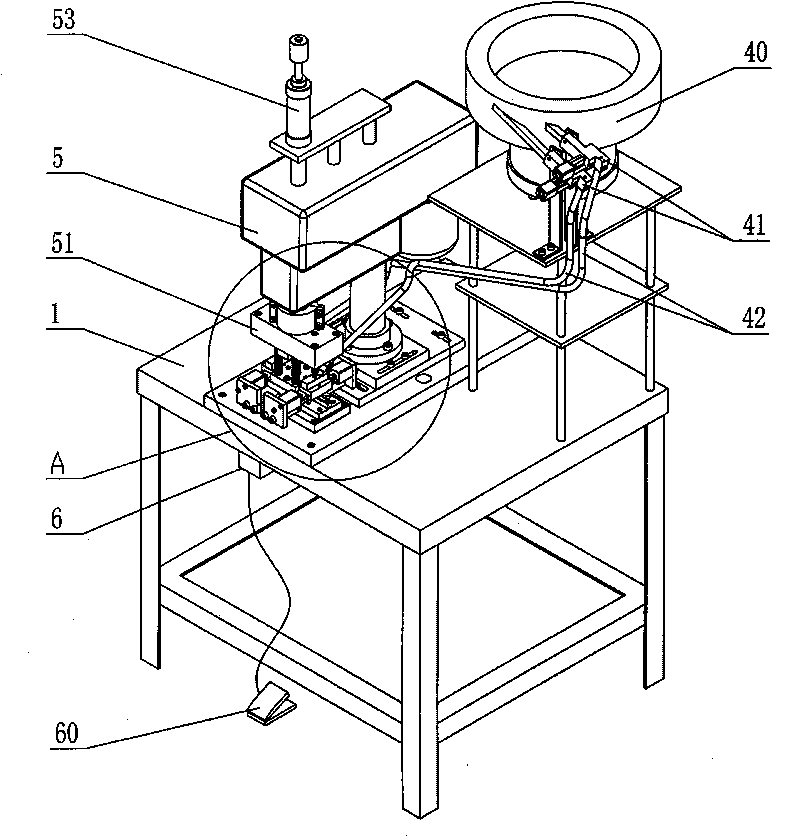

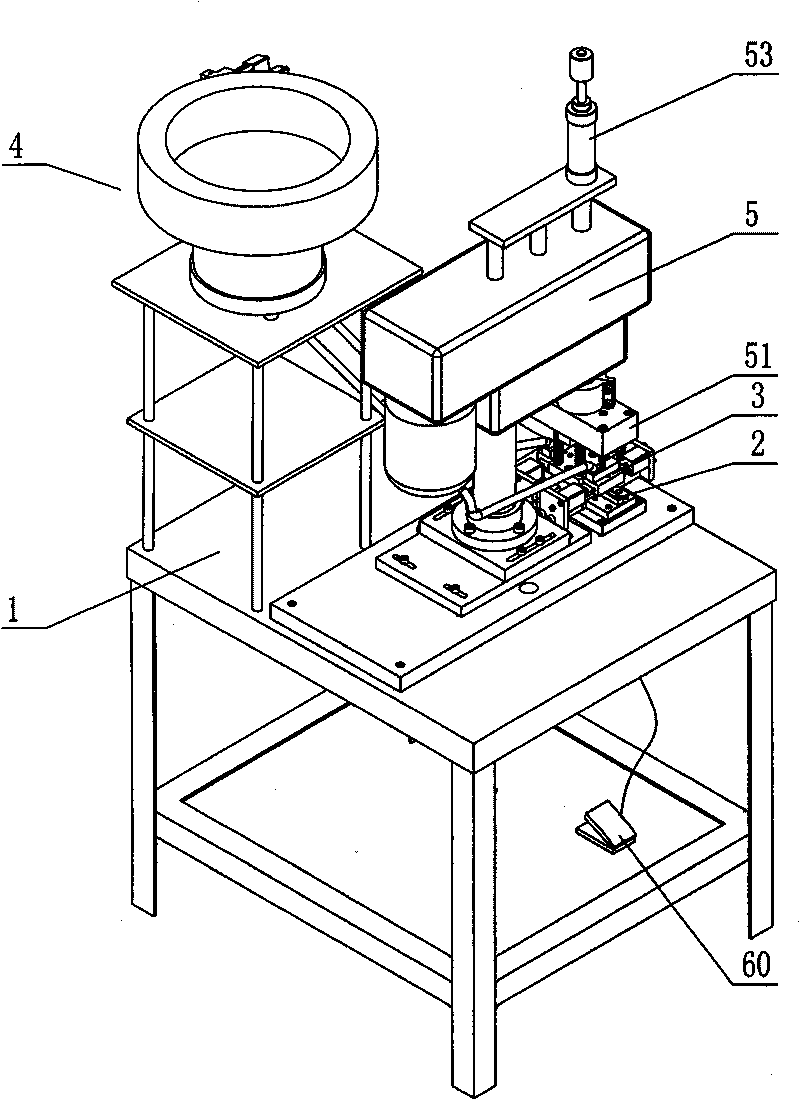

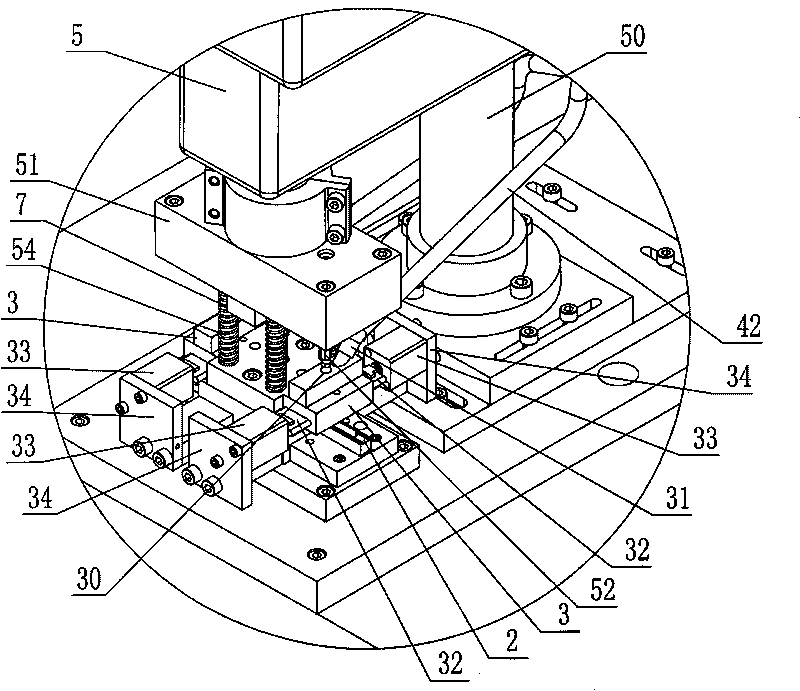

[0020] The specific implementation of the hinge assembly assembly machine of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 1-Figure 5 As shown, the hinge assembly assembly machine of the present invention is mainly composed of the base positioning seat 2 which is installed on the workbench 1 to position the fixed base 90 and the hinge arm assembly 91 of the hinge, and the screw positioning seat located above the base positioning seat 2 3. The screw feeding mechanism 4 that feeds the screw 92 to the screw positioning seat 3, the bench drill 5 electric control device 6 that assembles the screw 4 on the fixed base 90 and the hinge arm assembly 91, and the control switch 60 connected with the electric control device 6 . The screw positioning seat 3 includes a screw assembly guide hole 30 that penetrates up and down on the screw positioning seat 3, a blanking joint 31 that sends the screw 92 into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com