Adhesive-coated batten overturning and primary splicing mechanism of plank splicing machine

A jigsaw and gluing technology, which is used in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., to achieve the effect of improving efficiency, reducing costs, and reducing the participation of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Attached below Figure 1-3 And embodiment, the present invention is further elaborated:

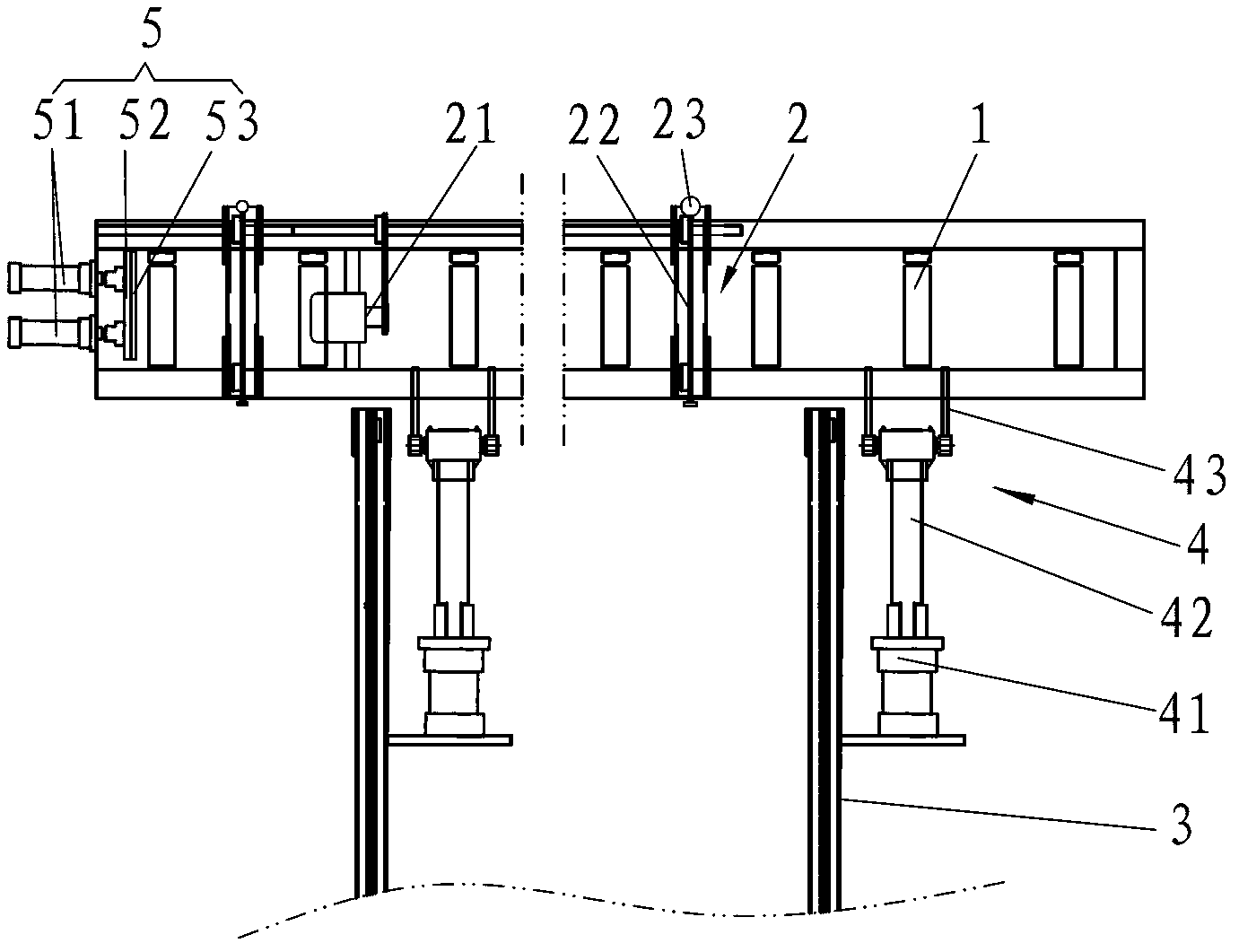

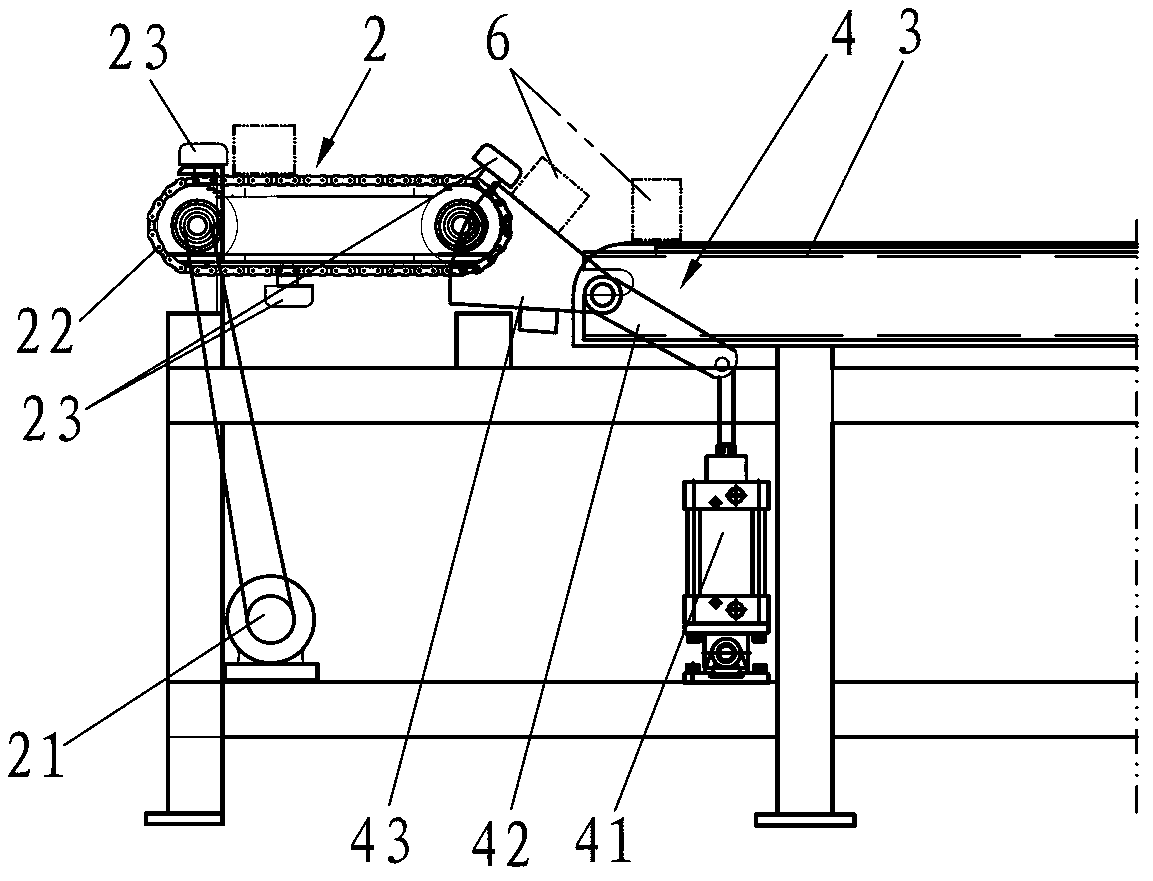

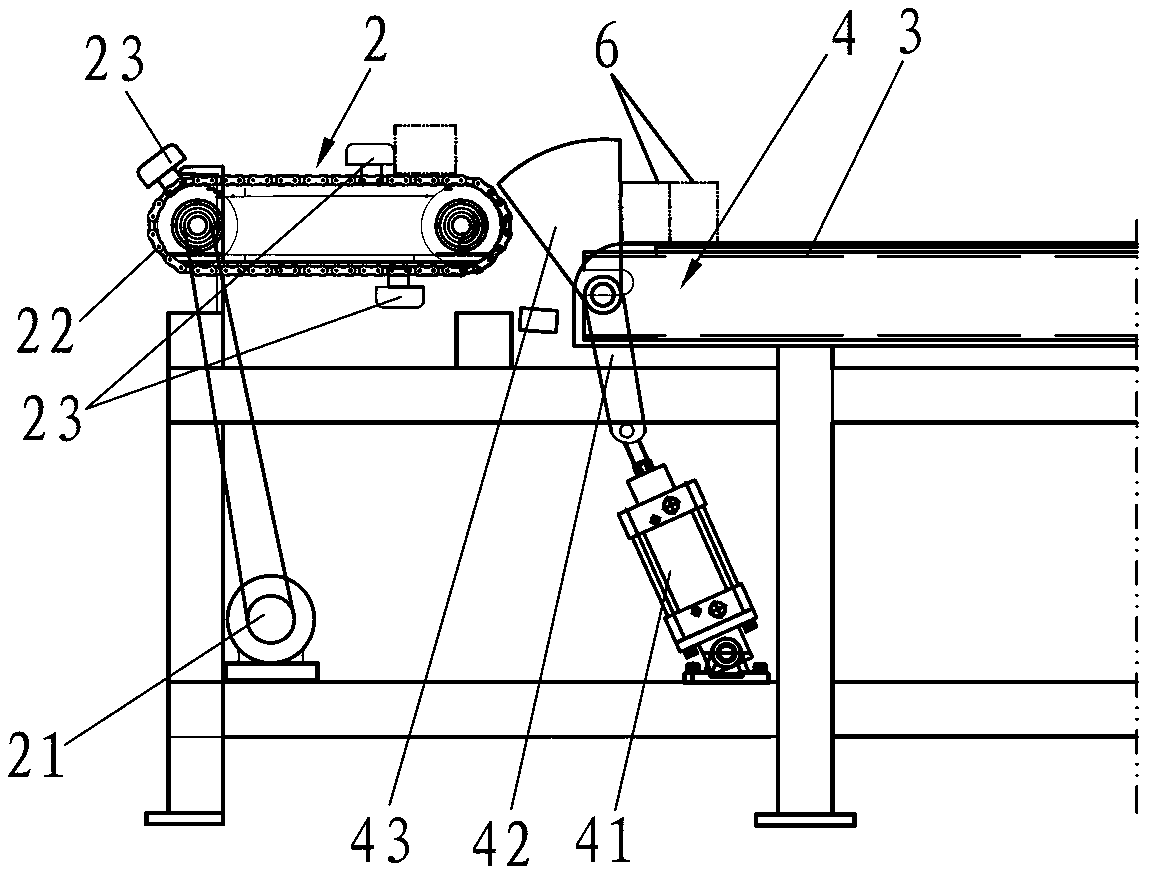

[0016] The glued wooden strips of the jigsaw machine turn over the initial assembly mechanism, and the initial assembly mechanism includes a group of incoming material conveying wheels 1; The lateral side is connected to the primary batching table 3, and a wood turning device 4 is arranged between the incoming material conveying wheel 1 and the primary batching table 3.

[0017] In order to reverse the initial assembly after aligning the incoming material, the incoming material conveying wheel 1 is provided with a buffer alignment device 5 at the end of the incoming material; the buffer alignment device 5 is a buffer baffle 52 for the cylinder 51, and the buffer baffle 52 is provided with a buffer on the incoming material surface Pad 53.

[0018] As a preferred embodiment, the horizontal material shifting device 2 is a group of horizontally driven sprockets 22 driven by a motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com