Layering device

The technology of layering device and station is applied in the field of material layering device and material layering device in electroplating equipment. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

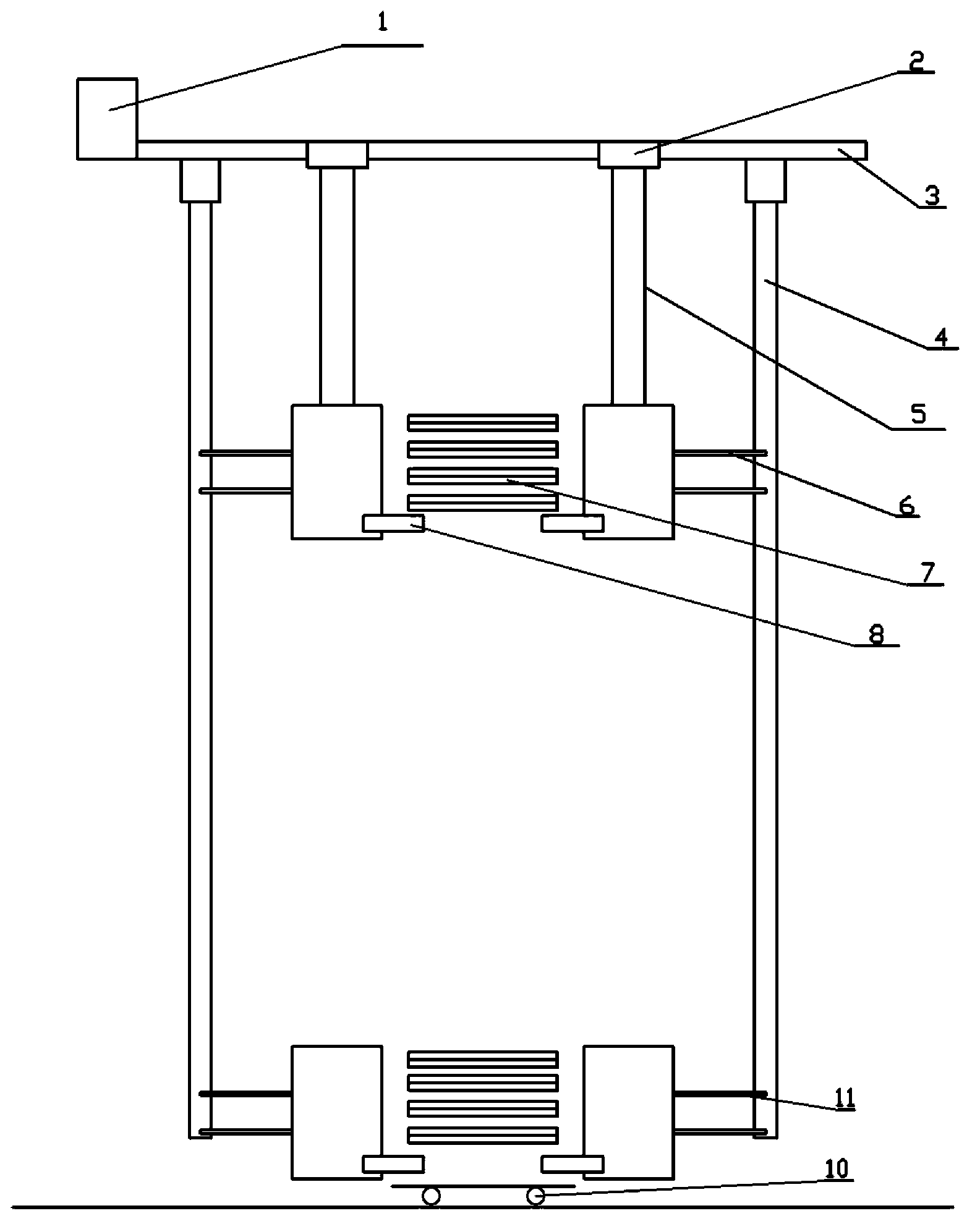

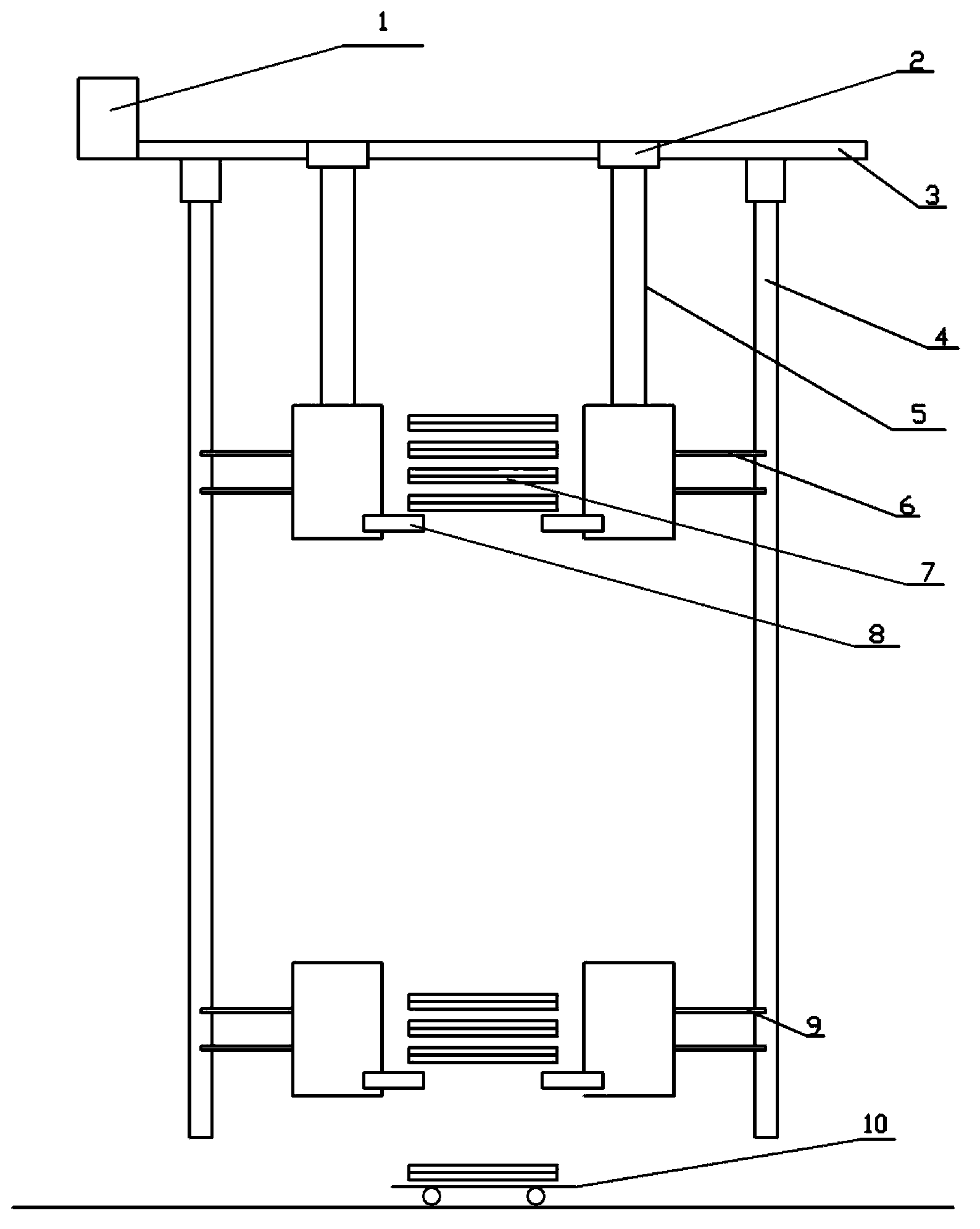

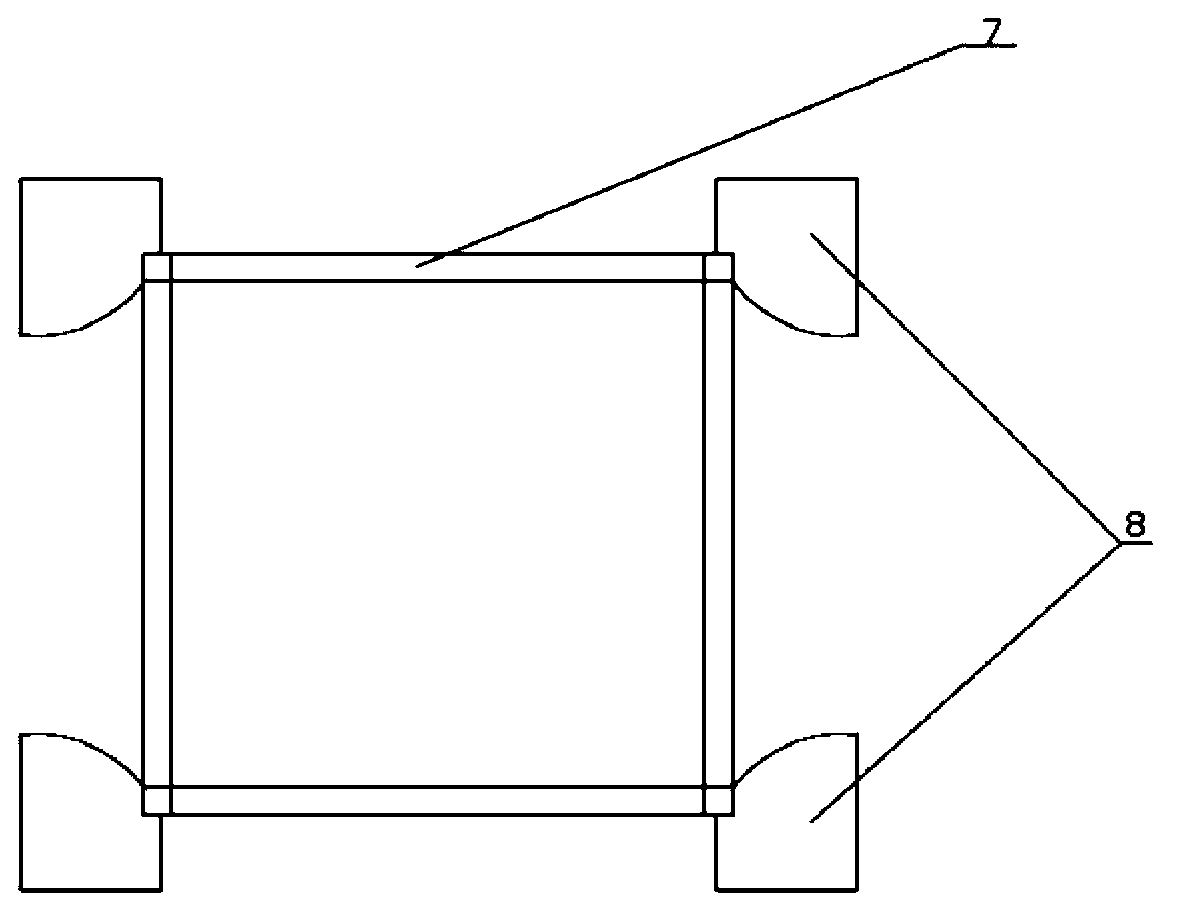

[0025] see figure 1 and figure 2 As shown, the layering device of this embodiment is at least used for supporting the superimposed carrier 7 at a first station 11, and a clamping mechanism that separates from the superimposed carrier 7 at the second station 9. The superimposed carrier 7 including more than one support tray arranged in a stack;

[0026] At least a sliding lifting mechanism for supporting the clamping mechanism to move back and forth between the first station 11 and the second station 9, and

[0027] Transport mechanism for transporting at least one or more trays separated from stacked trays 7 at the second station 9 .

[0028] The second station 9 is higher than the first station 11 by at least one disc height.

[0029] Specifically, the sliding lifting mechanism includes more than one set of vertical lifting mechanisms 4 for driving the clamping mechanism to move up and down between the first station 11 and the second station 9, and the vertical lifting me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com