Turnover device

A technology of turning over equipment and turning tables, which is applied in metal processing equipment, wind power generation, metal processing, etc., can solve the problems of low efficiency and difficult operation, and achieve the effect of high efficiency, small operation difficulty and less human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

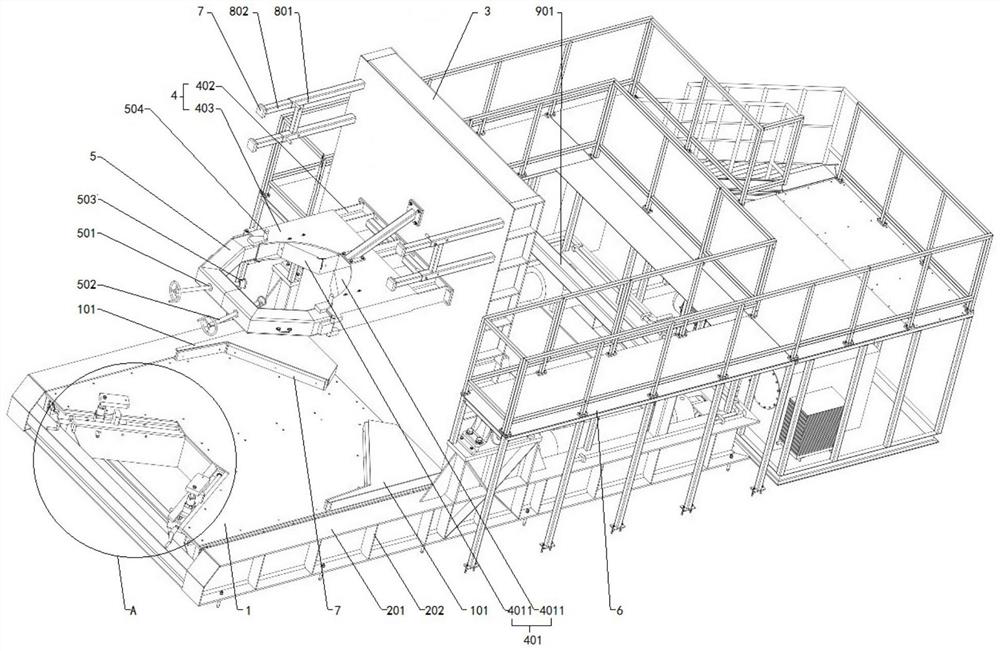

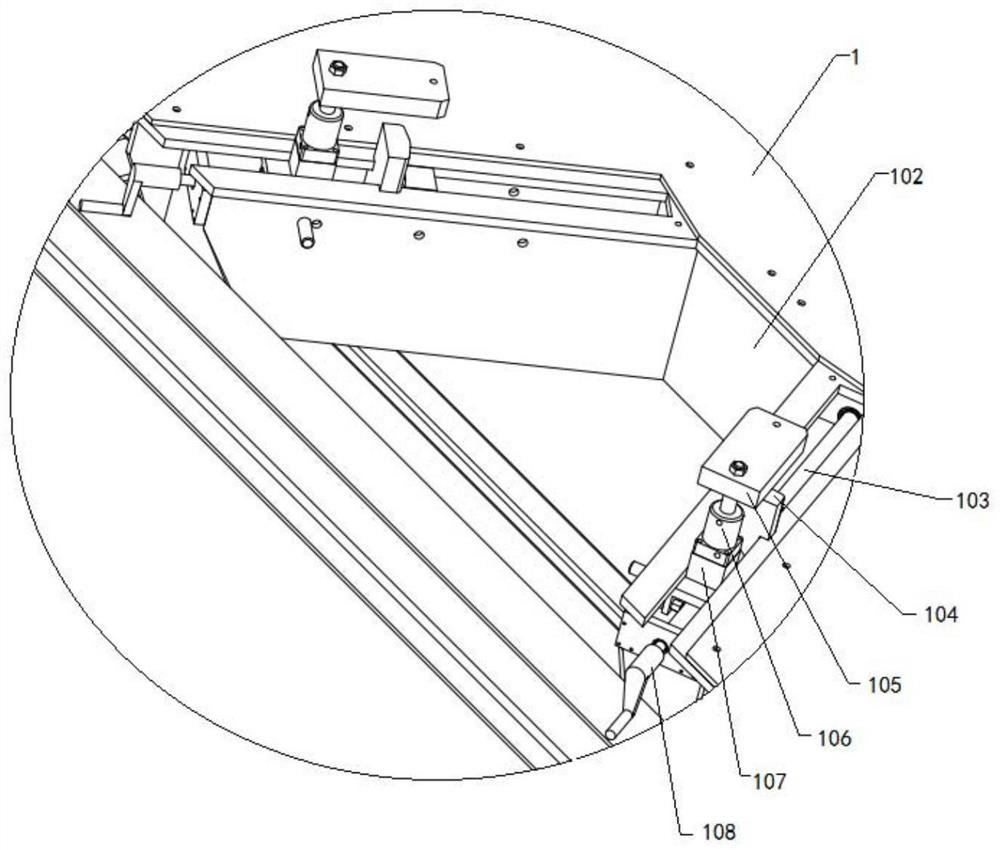

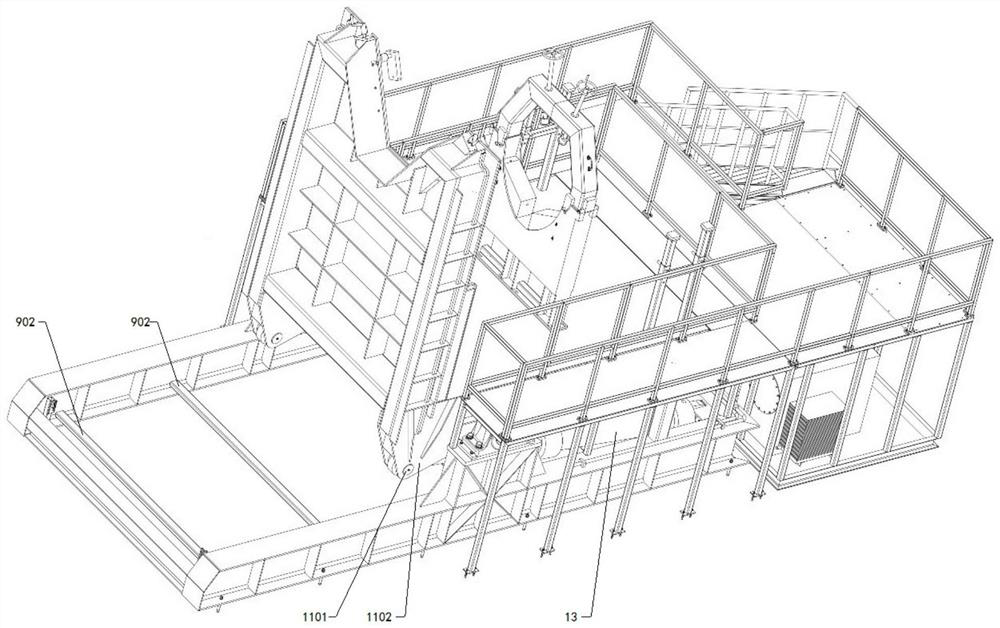

[0032] The state of the structure needs to be changed in the process of processing and assembling heavy and large mechanical structures. The method of crane hoisting and manual-assisted overturning of the structure has low efficiency and poor safety. The flipping device provided in this embodiment is intended to provide a flipping device with high efficiency and high safety.

[0033] Turning equipment, especially the turning equipment suitable for heavy and large mechanical structures, has a large area and high cost. Therefore, expanding the scope of application of the equipment to improve the utilization rate of the equipment and reducing the manufacturing cost from the side are also technical problems that need to be solved urgently. . For the flipping device provided in this embodiment, refer to Figure 5 and Image 6 , it is used to turn the main shaft 100 for wind turbines. It needs to face 7 specifications of the main shaft with bearing chamber 200 and without bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com