Method for improving photoelectric performance of perovskite

A technology of photoelectric performance and perovskite, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of difficult large-scale industrial production, difficult to control the thickness of two-dimensional perovskite, affecting device performance, etc., to improve quality control , convenient for large-scale industrial production, and the effect of high fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment relates to a kind of methylamine lead iodine (MAPbI 3 ) perovskite thin film is immersed in the method for forming two-dimensional perovskite passivation layer in the isopropanol solution of tetrabutylammonium iodide (TBAI) of 10mg / mL, described method comprises the steps:

[0053] 1) Dissolve 200mg tetrabutylammonium iodide in 20mL isopropanol to obtain solution A;

[0054] 2) methylamine lead iodide (MAPbI 3 ) The perovskite film is soaked in solution A for 5s;

[0055] 3) Remove isopropanol remaining on the surface of the film with an airflow, and anneal at 100° C. for 3 minutes.

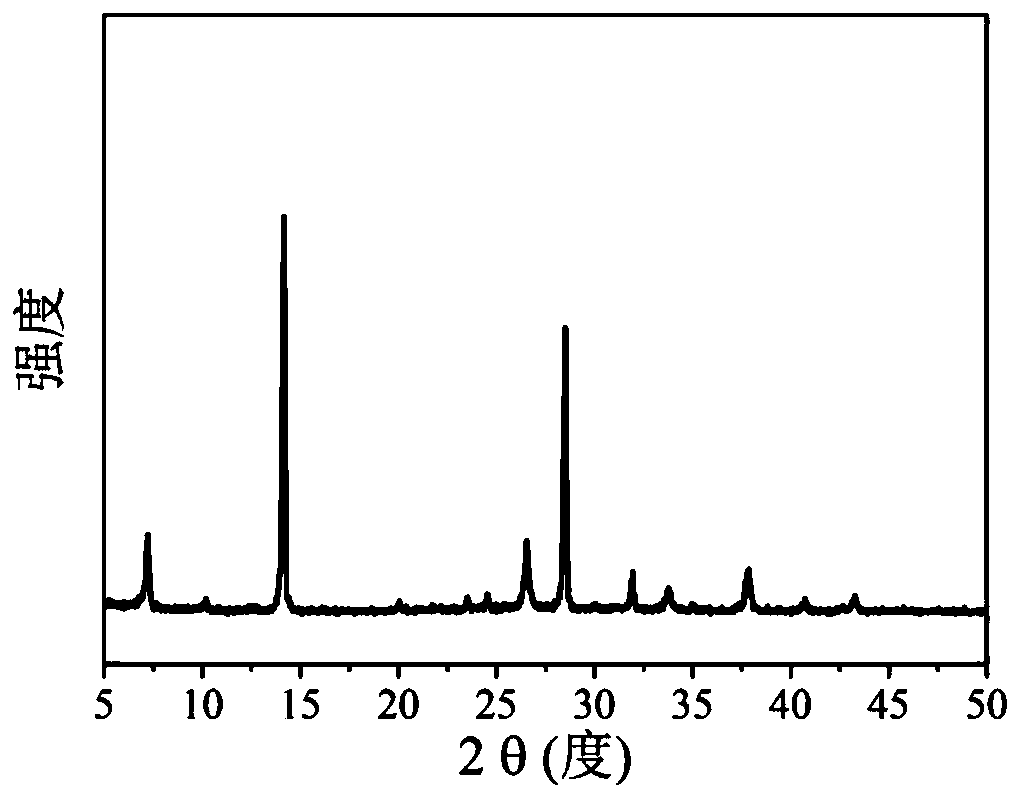

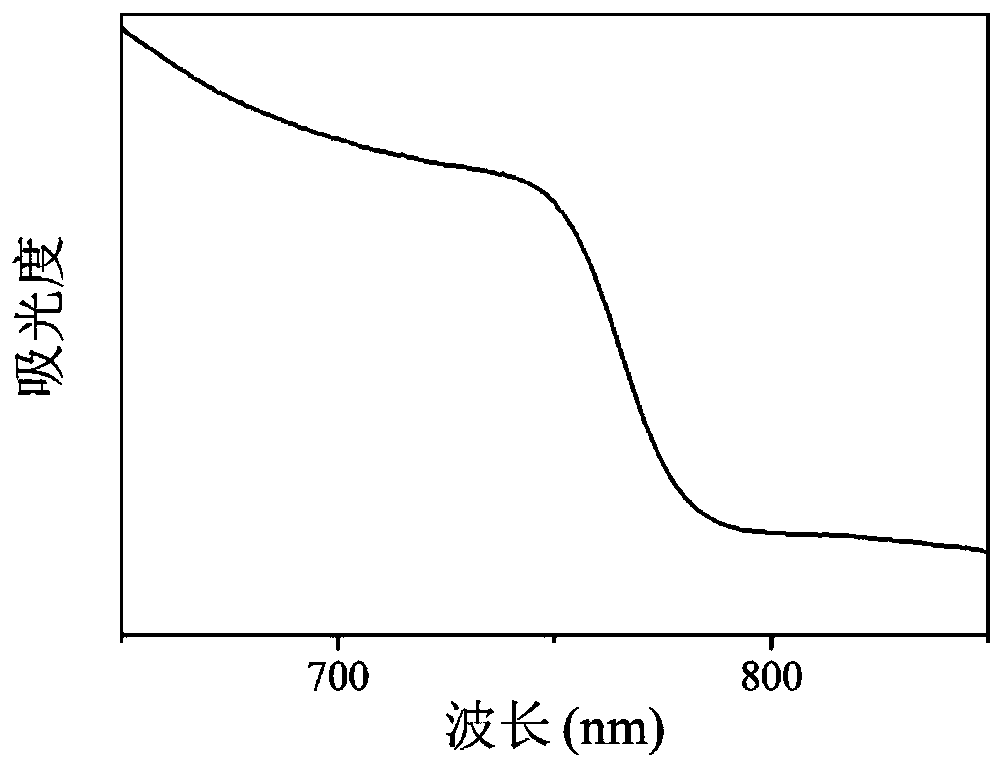

[0056] figure 1 Be the methylamine lead iodine (MAPbI) after the treatment of embodiment 1 3 ) X-ray diffraction spectrum of perovskite film, can find out that the MAPbI that embodiment 1 obtains therefrom 3 It maintains its original crystal structure, and the diffraction peak of two-dimensional perovskite appears at 7.2°; figure 2 Be the methylamine lead iodine (MAP...

Embodiment 2

[0058] The method of this embodiment is the same as in Example 1, except that the quaternary ammonium salt used in step 1) is benzyltrimethylammonium iodide, and the quality is 40 mg, and the soaking time in step 2) is 30 min. Figure 4 For the X-ray diffraction picture that embodiment 2 obtains, it can be seen that the MAPbI that embodiment 2 obtains 3 It maintains its original crystal structure, and the diffraction peak of 2D perovskite appears at 10.2°.

Embodiment 3

[0060] This embodiment relates to a kind of methylamine lead iodine (MAPbI 3 ) perovskite thin film is immersed in the method for forming two-dimensional perovskite passivation layer in the isopropanol solution of phenyltrimethylammonium iodide (PTAI) of 0.5mg / mL, described method comprises the steps:

[0061] 1) Dissolve 10mg of phenyltrimethylammonium iodide in 20mL of isopropanol to obtain solution A;

[0062] 2) methylamine lead iodide (MAPbI 3 ) Soak the perovskite film in solution A for 1h;

[0063] 3) Remove isopropanol remaining on the surface of the film with an airflow, and anneal at 100° C. for 3 minutes.

[0064] Figure 5 Be the methylamine lead iodine (MAPbI) after the processing of embodiment 3 3 ) X-ray diffraction spectrum of perovskite film, can find out that the MAPbI that embodiment 3 obtains therefrom 3 It maintains its original crystal structure, and the diffraction peak of two-dimensional perovskite appears at 7.1°; Figure 6 Be the methylamine lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com