Condenser type contact screen and its manufacture method

The invention relates to a technology of a capacitive touch screen and a manufacturing method, which is applied in the fields of electric digital data processing, photoengraving process of pattern surface, optics, etc., and can solve the problems of thick LCD touch screen, complicated calculation method, error-prone, etc., and achieves low cost, high production Process optimization, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

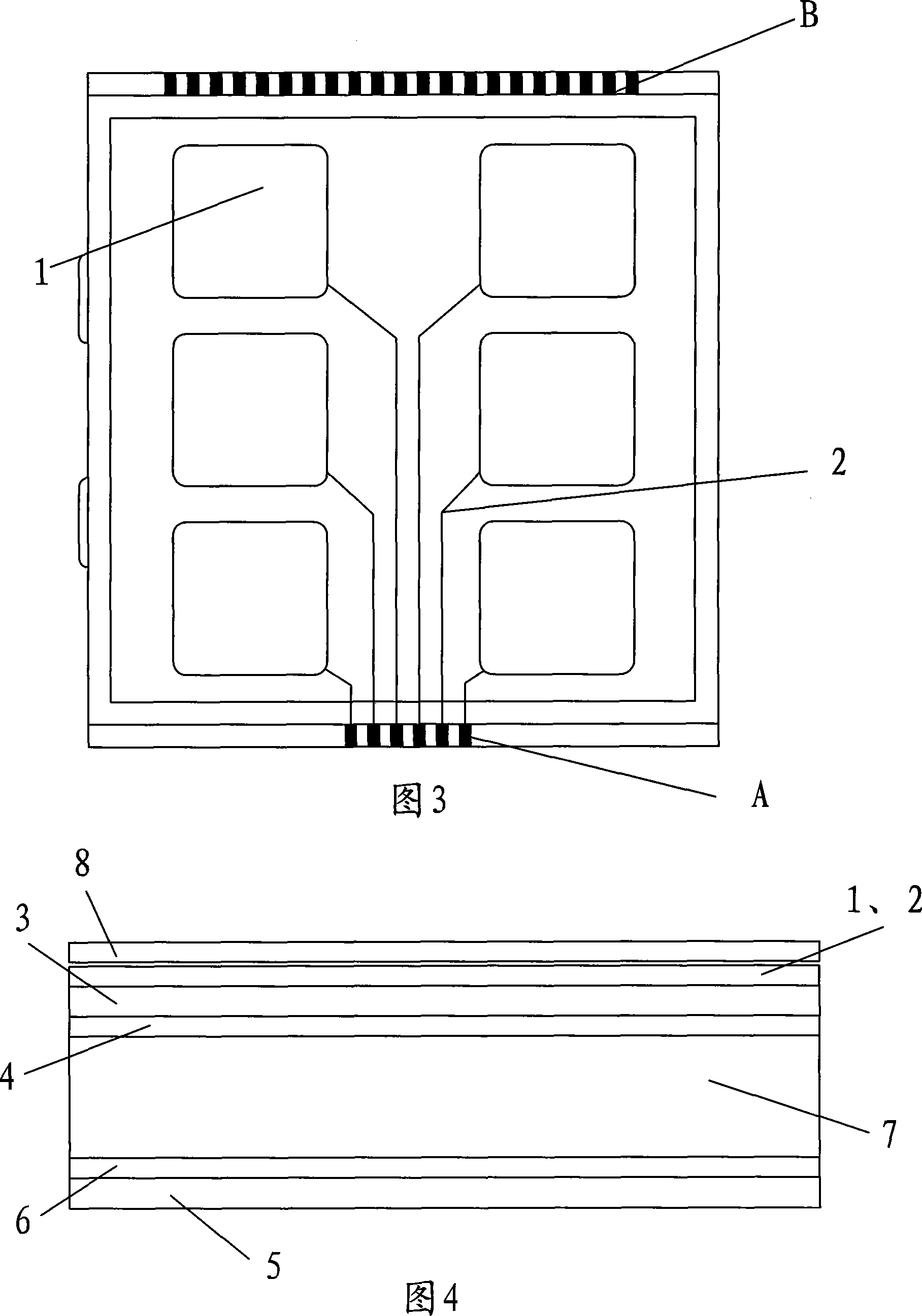

[0031] The capacitive touch screen of the present invention uses an exposure etching process to make required button shapes and lines on the ITO glass. The lead-out method of the touch screen can adopt methods such as FPC or pins or zebra strips. Use the exposure etching process to make the required button shape and circuit on the ITO glass.

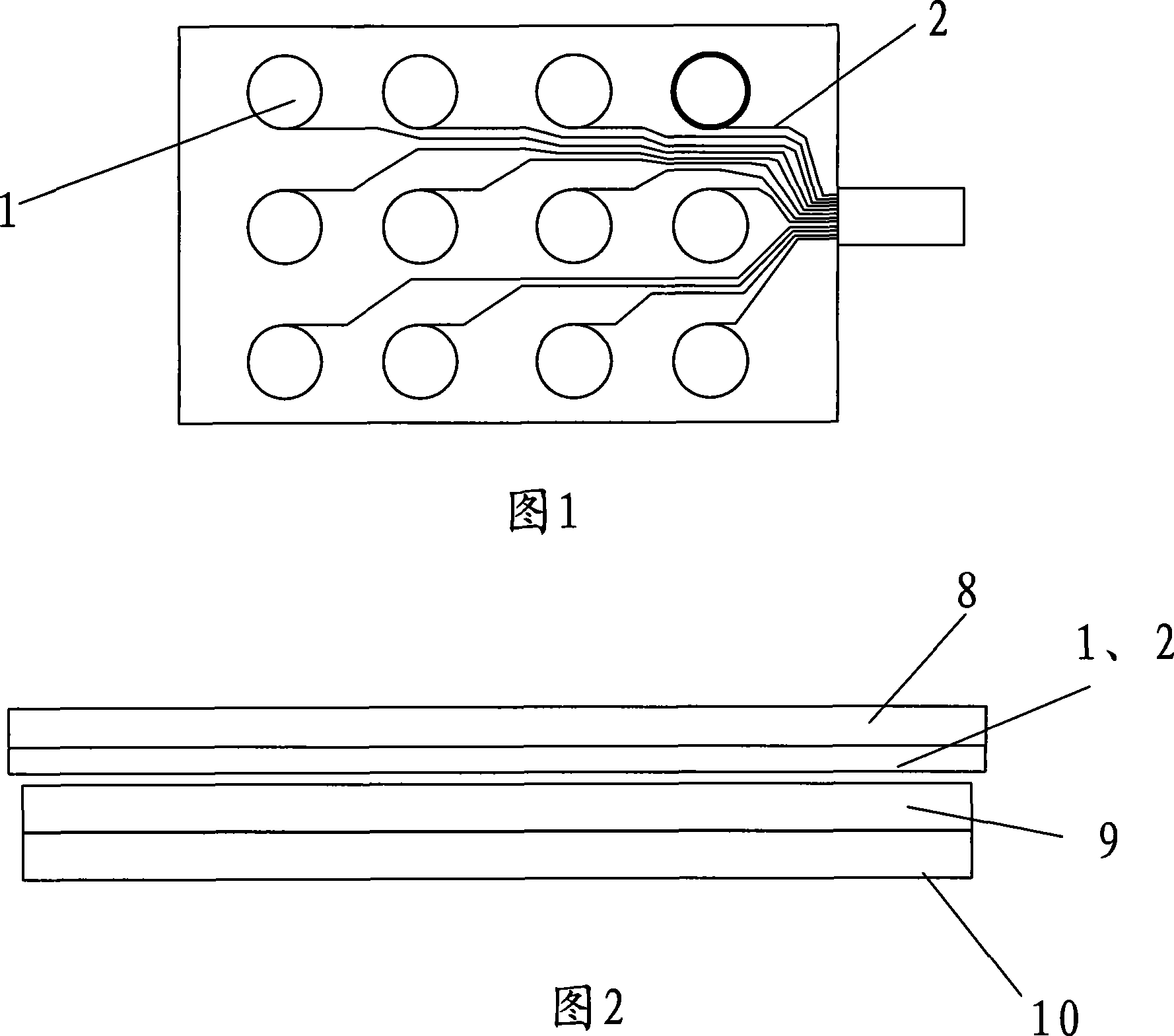

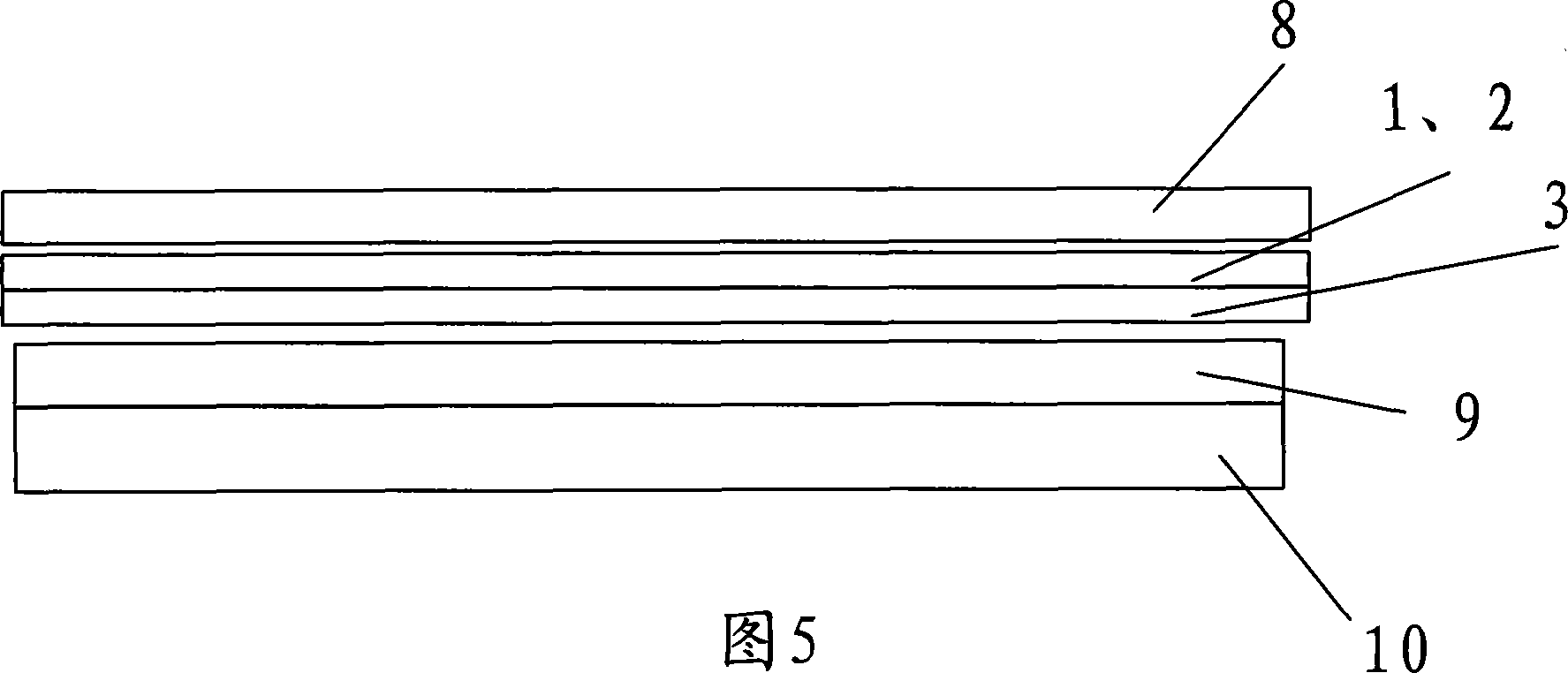

[0032] The structure of the first embodiment of the present invention is described in conjunction with FIG. 1 and FIG. 2. The capacitive touch screen of the present invention includes an indium tin oxide layer, a transparent protective layer 8 arranged above the indium tin oxide layer, and the indium tin oxide layer The shape of the key 1 is etched on the top, and each key 1 is led out by one or more etched lines 2 , and the key 1 is connected to the control circuit through the lines 2 . Line 2 can be led out by means of FPC or pins or zebra strips. A liquid crystal display 9 is provided below the buttons 1 and lines 2 , and a liquid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com