High-temperature bluing device for iron pan

An iron pan and baking blue technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of low efficiency, delay time, low degree of automation, poor fixing stability, etc., to achieve automatic switching, The effect of high automation intensity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

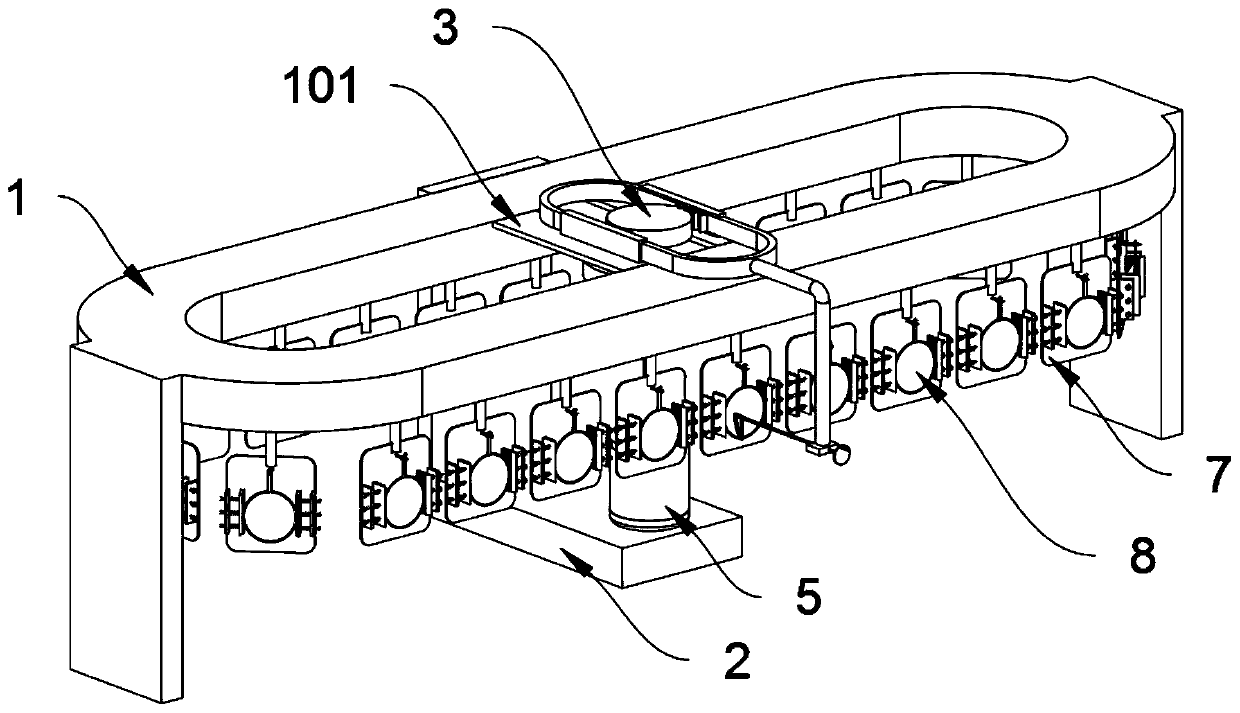

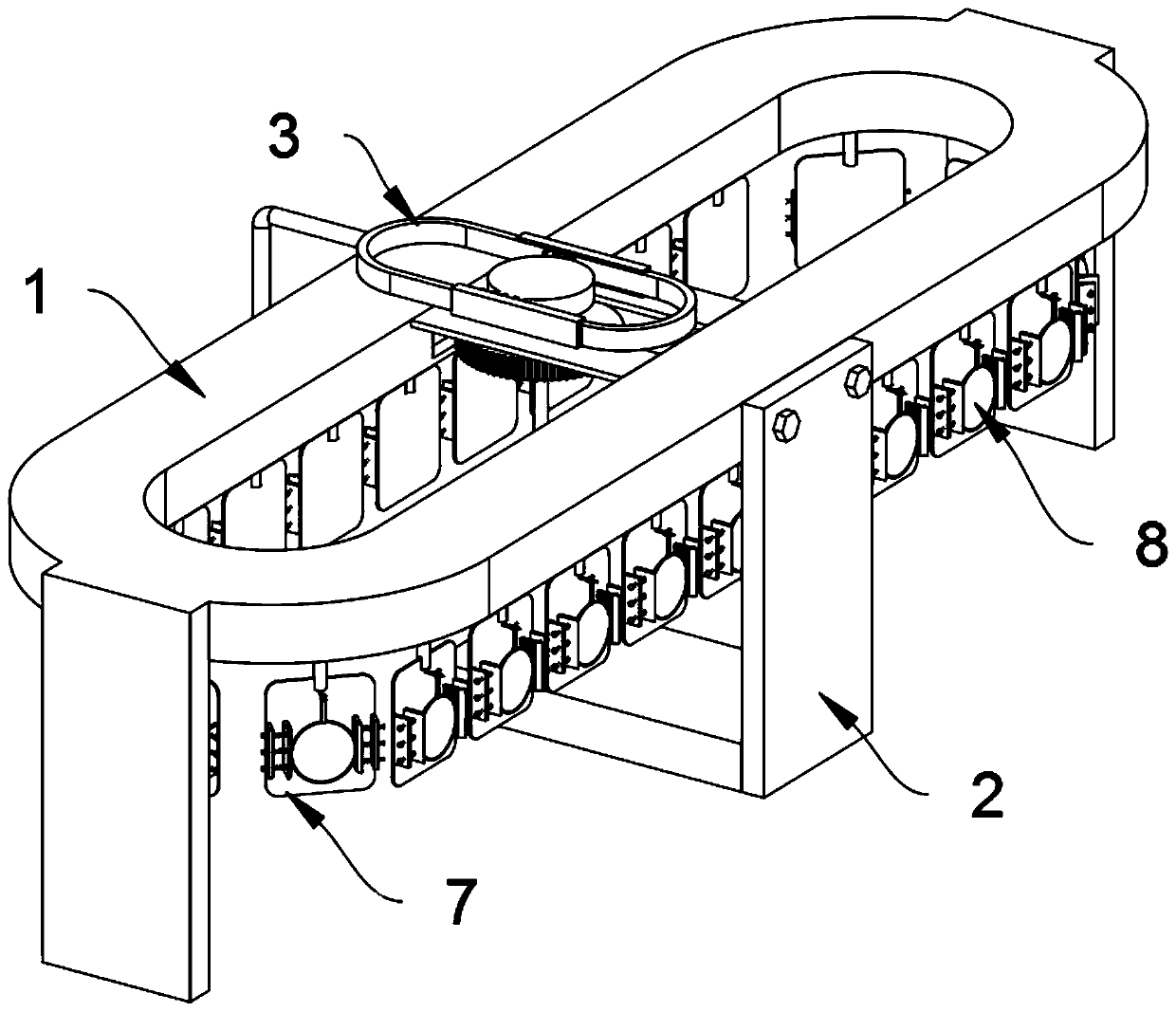

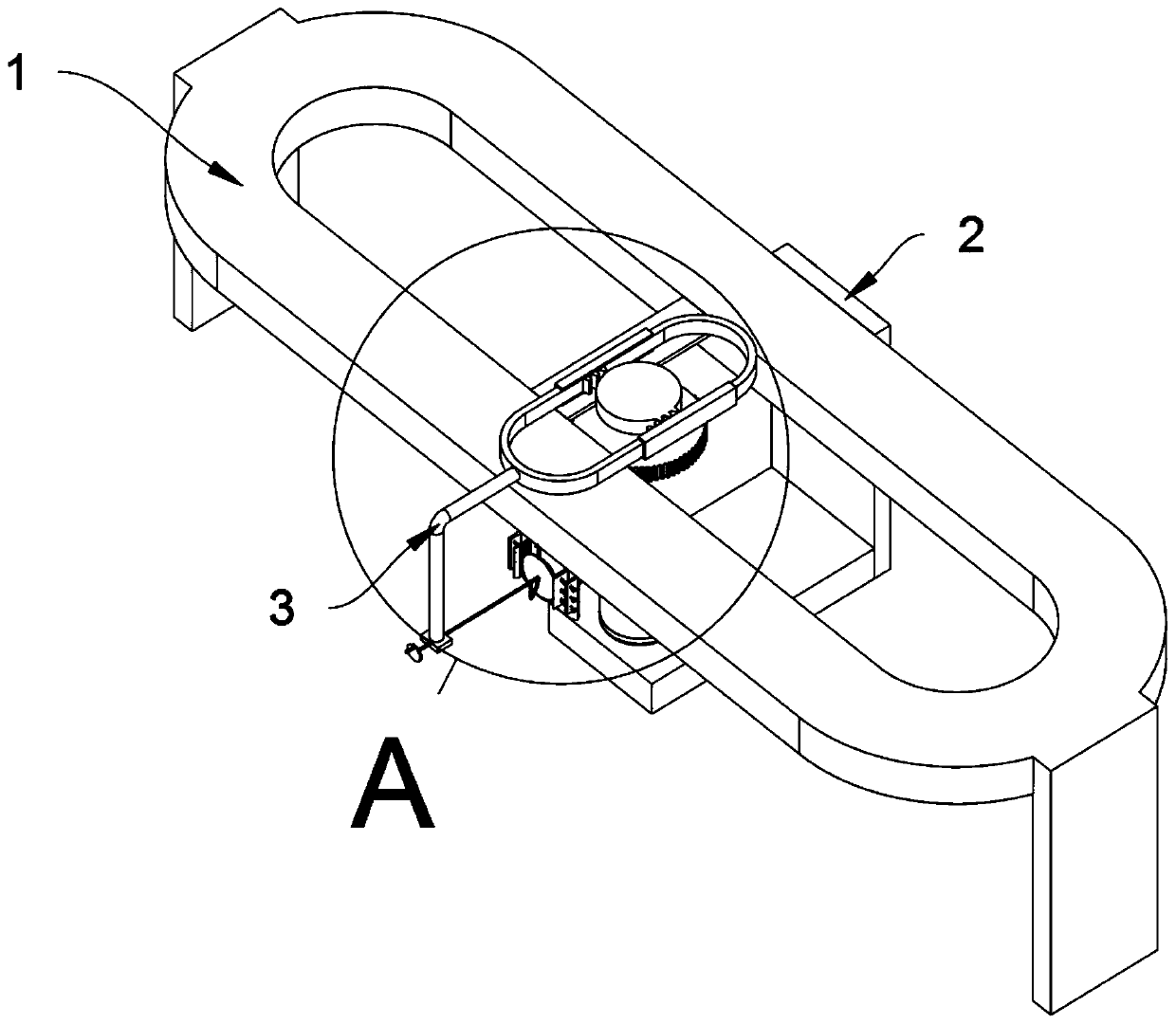

[0035] as attached figure 1 to attach Figure 10 Shown:

[0036] The invention provides a high-temperature blushing device for iron pans, comprising a circulating chain 1; a motor mounting seat 2 is fixedly connected to the left side of the bottom of the circulating chain 1 through bolts, and a servo motor 5 is fixedly connected to the top of the motor mounting seat 2; Two installation seat plates 101 are welded on the chain 1, and a nozzle seat adjustment structure 3 is welded in the middle of the top of the two installation seat plates 101; refer to image 3 ,4 , 5 and Figure 6 The nozzle seat adjustment structure 3 includes a sliding seat 301, a circular gear seat 302, an incomplete gear A303 and a nozzle seat connecting seat 304. There are two sliding seats 301, and the two sliding seats 301 are welded to the mounting seat plate 101 The top surface; the round tooth seat 302 is slidably connected to the sliding seat 301, and the round tooth seat 302 is symmetrically pro...

Embodiment 2

[0040] On the basis of embodiment 1, refer to as Figure 9 , also includes an iron pan mounting seat structure (7), the bottom of the circulating chain (1) is fixedly connected with an iron pan mounting seat structure (7), and an iron pan (8) is buckled on the iron pan mounting seat structure ), the iron pan mounting seat structure 7 includes a mounting seat main body 701, a rectangular plate 702, a splint 703, a limit sliding rod 704, an elastic member 705, a rubber pad 706 and a hook 707, and two rectangles are symmetrically welded on the mounting seat main body 701. plate 702, and three limit sliding rods 704 are slidably connected on each rectangular plate 702; a splint 703 is welded on the ends of the three limit sliding rods 704, and a splint 703 is sleeved on the limit sliding rod 704 for reset of the splint 703. The elastic part 705, the left and right sliding of the splint 703 and the suspension of the hook 707 during use can facilitate the fast clamping and fixing of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com