Integrated solid state fermentation reactor and application thereof

A solid-state fermentation and reactor technology, applied in the field of integrated solid-state fermentation reactors, can solve the problems of restricting the rapid development of solid-state fermentation technology, lack of mass transfer and heat dissipation, and narrow application scope, and achieves remarkable drying effect, uniform heating, and avoidance of impurities. The effect of bacterial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

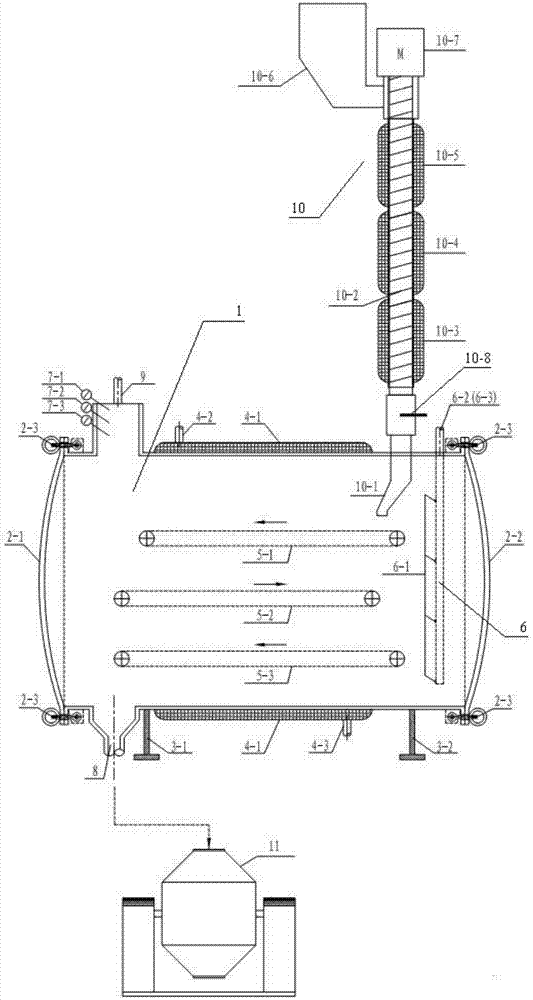

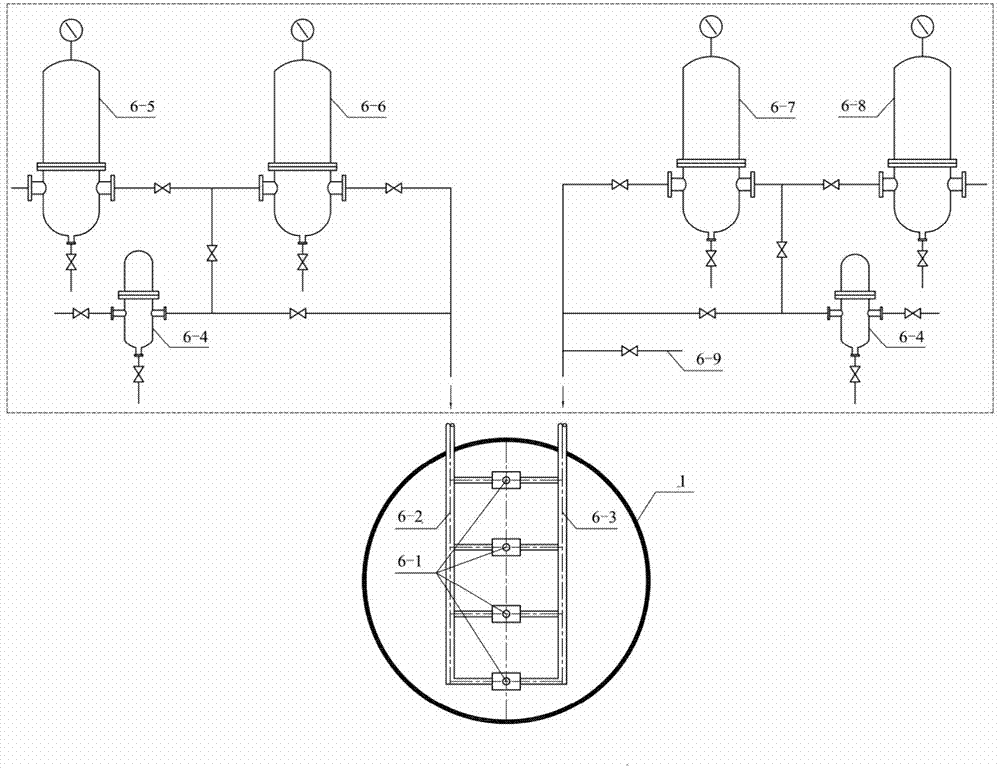

[0047] like figure 1 The solid-state fermentation belt reactor shown includes a fermenter 1, a medium preparation tank 10 and a conveyor belt system 11; wherein the fermenter 1 is a stainless steel horizontal fermenter, and the first support 3-1 at the bottom and the second The support 3-2 is fixed on the base 3. A jacket 4-1 is provided on the outer periphery of the fermenter, and the jacket 4-1 is provided with a heat exchange medium inlet 4-2 and a heat exchange medium outlet 4-3, and the heat exchange medium inlet 4-2 is arranged on the jacket 4 -1 is at the top, the heat exchange medium outlet 4-3 is located at the bottom of the jacket 4-1, and the heat exchange medium inlet 4-2 and the heat exchange medium outlet 4-3 are far apart in the horizontal direction. The heat exchange medium is water vapor and circulating cooling water.

[0048]A first movable top cover 2-1 and a second movable top cover 2-2 are arranged on both sides of the fermentation tank 1 in the horizont...

Embodiment 2

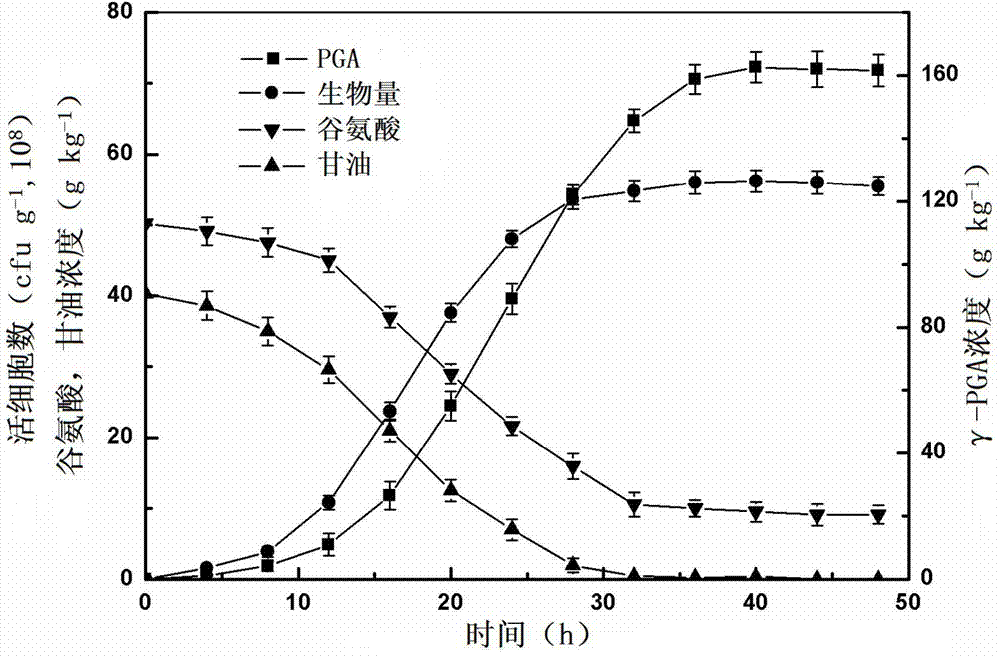

[0054] Embodiment 2: Aerobic microbial solid-state fermentation (taking Bacillus subtilis solid-state fermentation to produce gamma-polyglutamic acid agricultural fertilizer as an example)

[0055] γ-polyglutamic acid (γ-PGA) is a kind of homopolyamino acid synthesized by microorganisms. The basic skeleton is formed by linking L-glutamic acid and D-glutamic acid through γ-amide bonds. straight-chain molecules, with a relative molecular mass of up to 200×10 4 Da. Due to the existence of a large number of hydrogen bonds and hydrophilic free carboxyl groups in its structure, it has excellent moisture retention properties and has been widely used in agricultural fertilizers.

[0056] The microorganism fermented in the present embodiment is the Bacillus subtilis NX-2 ((bacteria strain preservation number: CGMCC 0833) that this laboratory has obtained authorization, directly uses microbial bacterial agent (5 * 10 10 cfu / g) inoculation, the inoculation amount is 25g / kg.

[0057] S...

Embodiment 3

[0061] Embodiment 3: aerobic microorganisms take solid-state fermentation of Bacillus subtilis phosphate-solubilizing bacteria bacterial agent as an example

[0062] Phosphorus is one of the essential nutrients for plant growth and development. Soil phosphorus deficiency directly affects the growth of crops and food production. In my country, the area of phosphorus-deficient cultivated land reaches 74%, and more than 95% of the phosphorus in the soil is in an invalid state, which is difficult to be absorbed. Plants directly absorb and utilize. There are many phosphorus-solubilizing microorganisms in the soil, which can degrade these insoluble phosphates into free forms for plant absorption and utilization. Therefore, it is necessary to develop phosphorus-solubilizing microorganisms, reduce the production cost of phosphate fertilizers, solve the pollution of phosphate fertilizers and improve the utilization rate of phosphorus. Research is necessary.

[0063] The phosphate-sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com