Automatic capping device for beverage production

An automatic and beverage technology, which is applied in the directions of tightly closing containers with lids, packaging, and application, can solve problems such as affecting product quality, difficult to ensure cleanliness and hygiene, and difficult for workers to withstand mass production tasks on production lines, achieving high automation strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

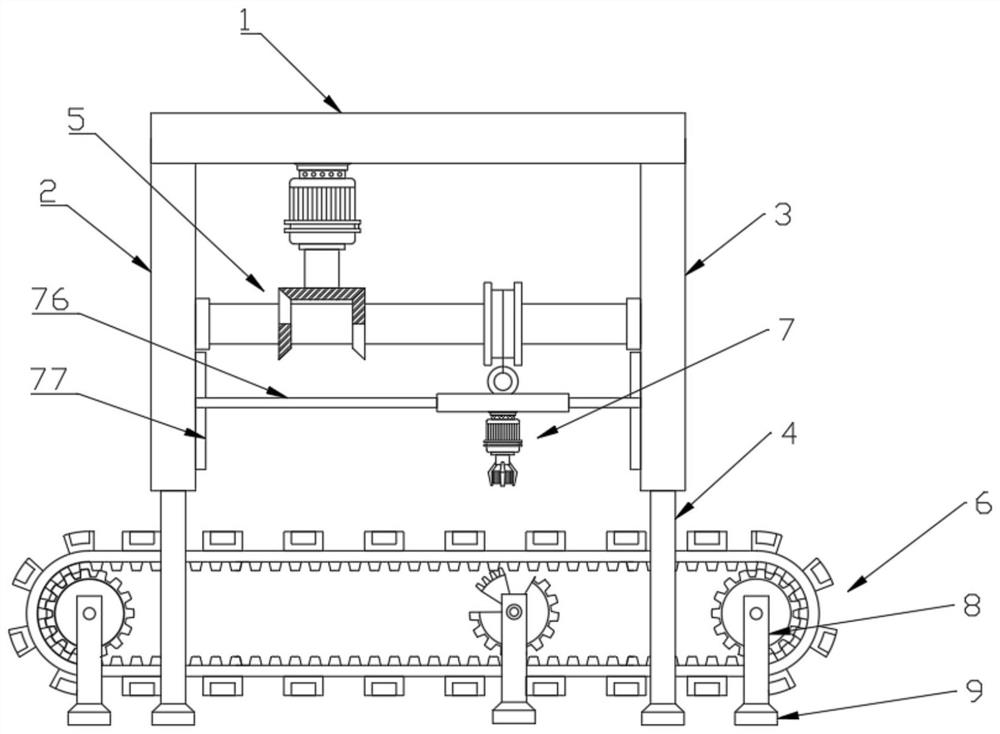

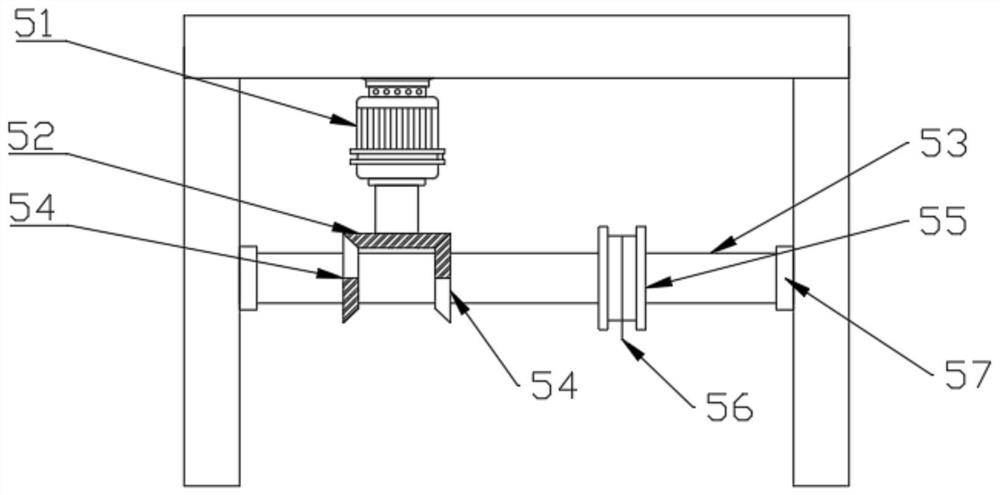

[0024] see Figure 1-5 , an automatic upper cover device for beverage production, comprising a beam plate 1, a left side plate 2, a right side plate 3, a support column 4, a drive mechanism 5, a transport mechanism 6 and an upper cover mechanism 7, the left side plate 2 and the The front and rear ends of the bottom of the right side plate 3 are fixedly connected with the support columns 4, and the top surfaces of the left side plate 2 and the right side plate 3 are fixedly connected to the left and right sides of the bottom surface of the beam plate 1;

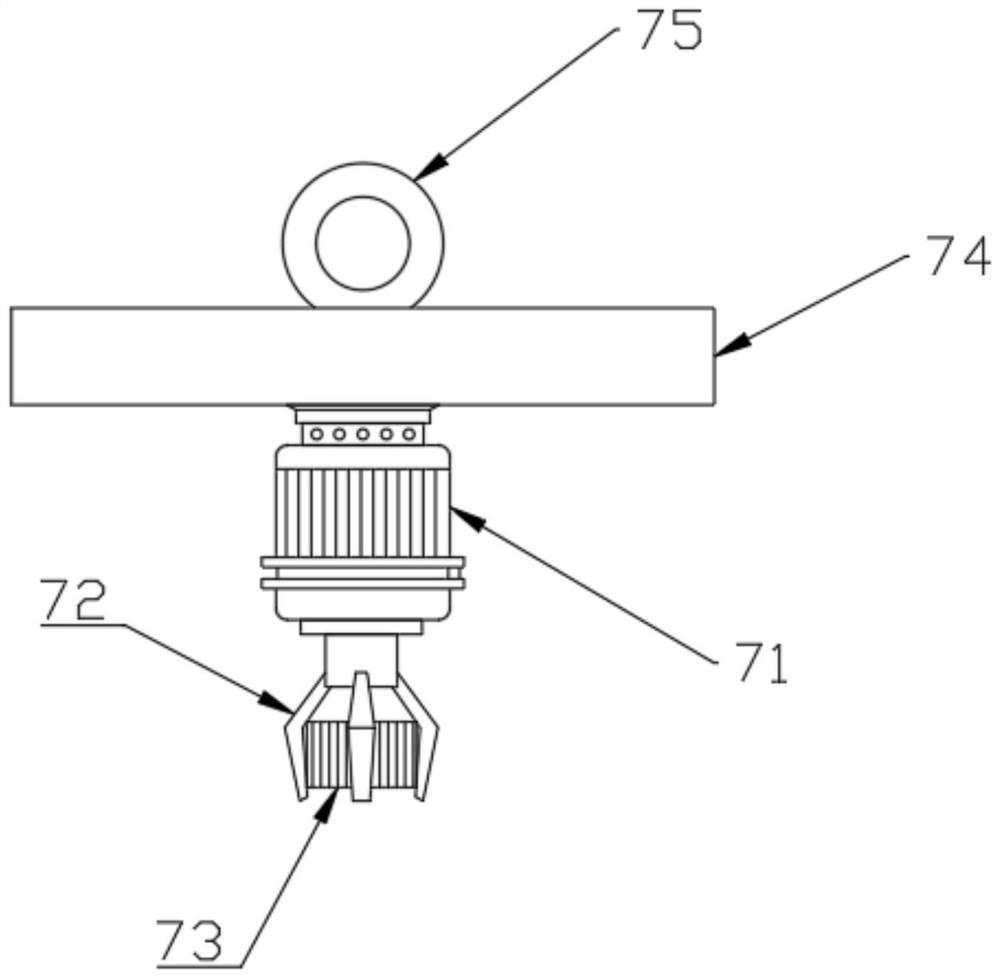

[0025] The upper cover mechanism 7 includes a second motor 71, a three-claw gripper 72, a bottle cap 73 and a fixed frame 74, the bottom surface of the fixed frame 74 is fixedly connected with the second motor 71, and the output shaft of the second electric motor The bottom end is provided with the three-claw grip 72, and the three-claw grip 72 is clamped with the bottle cap 73;

[0026] The transport mechanism 6 includes a c...

Embodiment 2

[0034] This embodiment is a further improvement made on the basis of Embodiment 1, specifically as follows:

[0035] see Figure 1-5 , the left and right sides of the fixed frame 74 are fixedly connected with a balance bar 76, and the end of the balanced bar 76 away from the fixed frame 74 is slidably installed on a slide rail 77, and the bottom surface of the slide rail 77 is fixedly connected with the left side On the side wall adjacent to the board 2 and the right side board 3 , the balance bar 76 acts as a balance guide to avoid shaking during the up and down reciprocating movement of the fixing frame 74 .

[0036] The bottom ends of the column 8 and the support column 4 are all fixedly connected with a shock-proof foot pad 9, and the shock-proof foot pad 9 has played a role of shock absorption and shock absorption, reducing the vibration generated by the device when the motor rotates far away, increasing the The overall stability of the device.

[0037] The last few point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com