Mining method with mining-dressing and filling treatment

A mining method and mine technology, applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of polluting the ecological environment, increasing the cost of equipment, spontaneous combustion of gangue, etc., and achieving a simple process system, less equipment water consumption, and sorting particle size. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

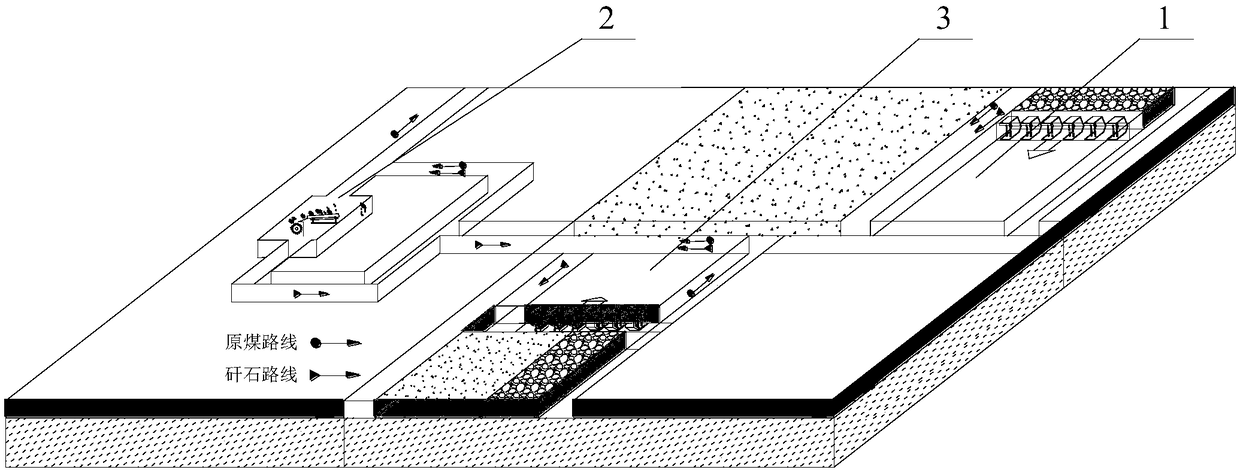

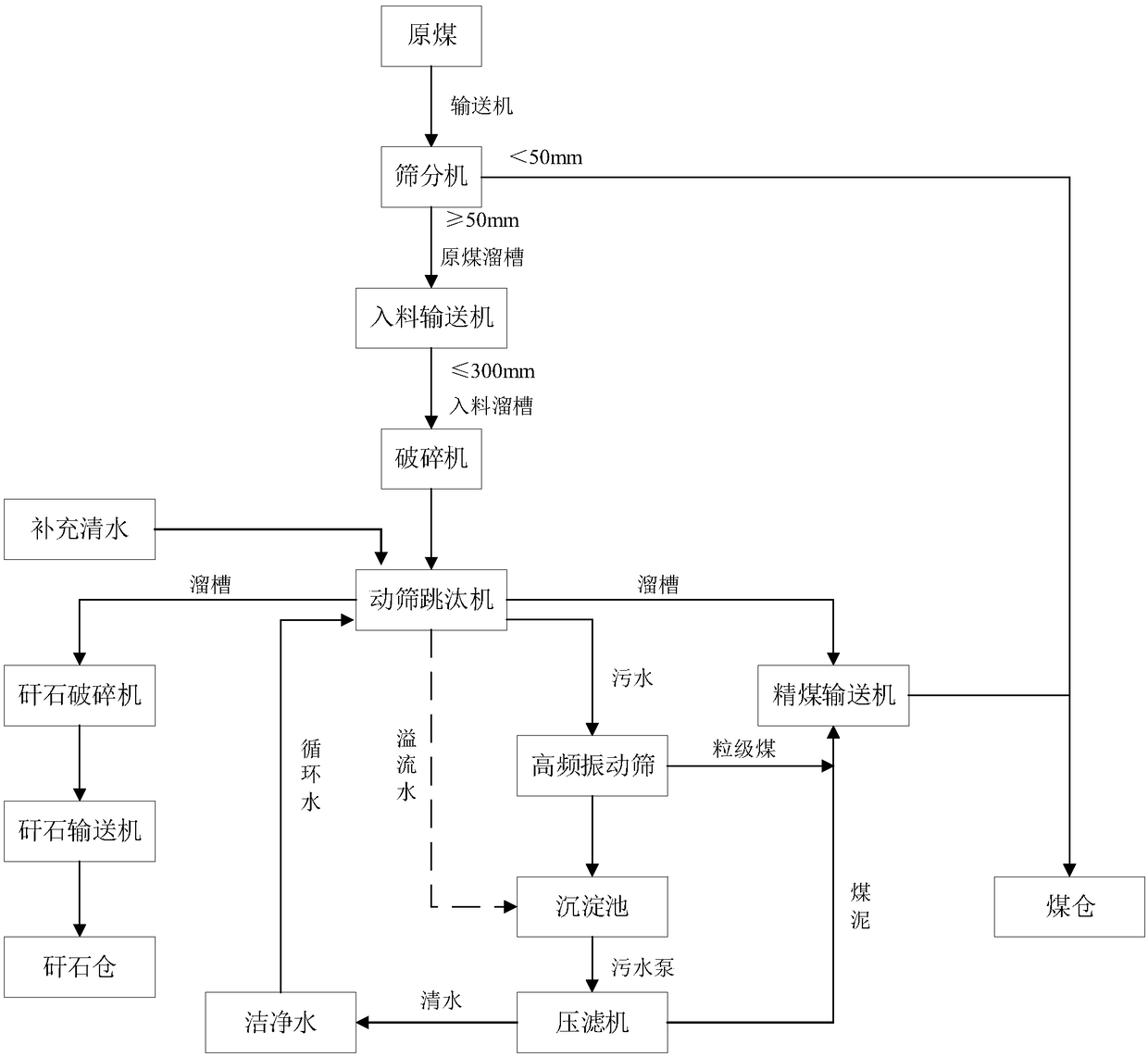

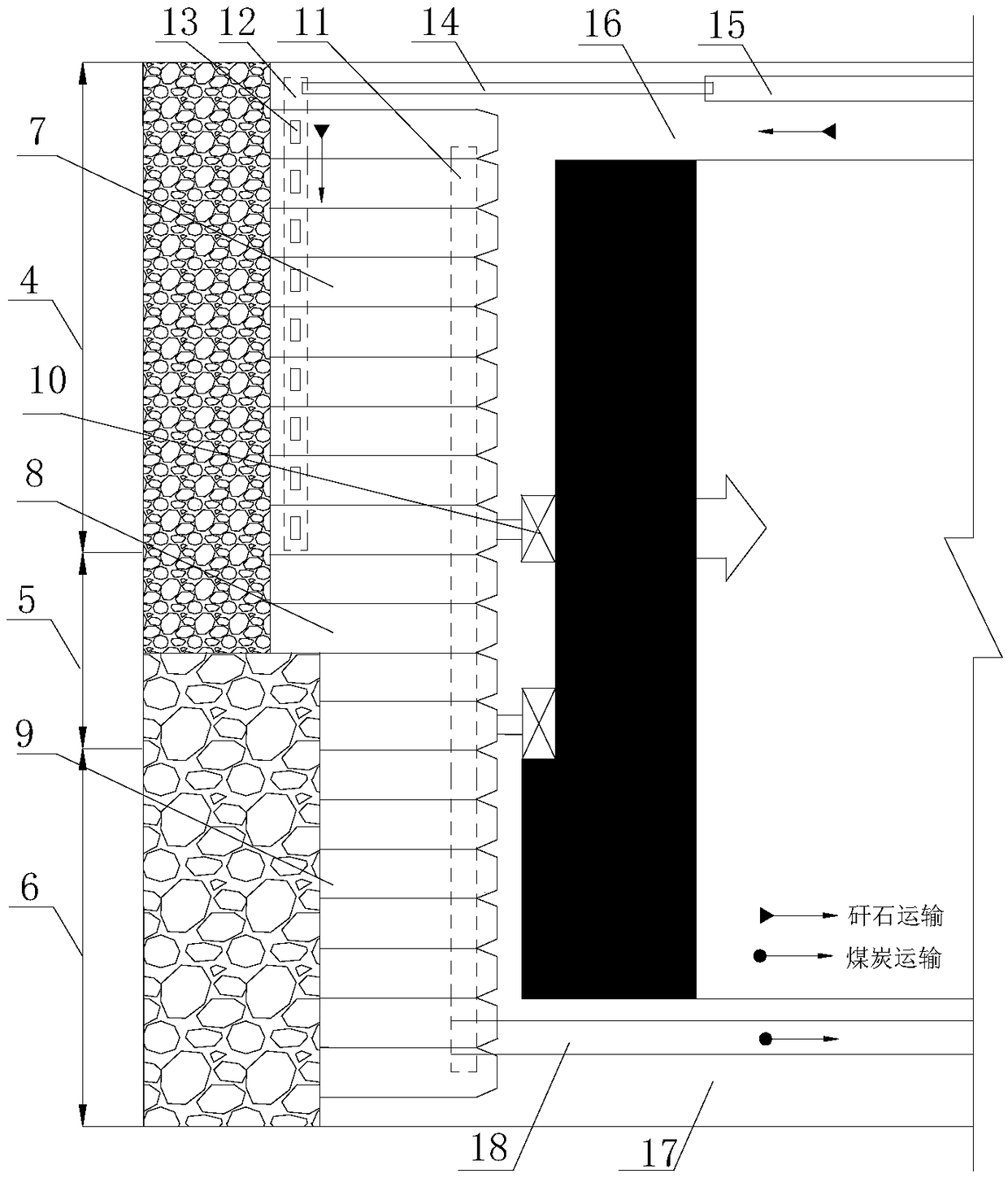

[0037] Such as figure 1 with Figure 4 As shown in the figure, a mining method for mining, filling and filling in mines, this method needs to arrange three systems underground, including a small amount of gangue mining system 1, a coal gangue sorting system 2, and a gangue filling and coal efficient recovery system 3, each system The working ability should meet the following principles: the designed filling capacity of gangue filling and high-efficiency coal recovery system > the sorting gangue capacity of the coal gangue sorting system > the gangue output capacity of the gangue small amount mining work system.

[0038] Specific steps are as follows,

[0039] The first step is to clearly design the main source of gangue in the mining face according to the geological conditions and occurrence characteristics of the coal seam;

[0040] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com