Pneumatic concentrating machine

A technology for wind-powered concentrators and concentrates, which is used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of high work intensity, irregular replacement of consumables, and low recovery rate, etc. To achieve the effect of large separation particle size range, strong separation process and large particle size range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

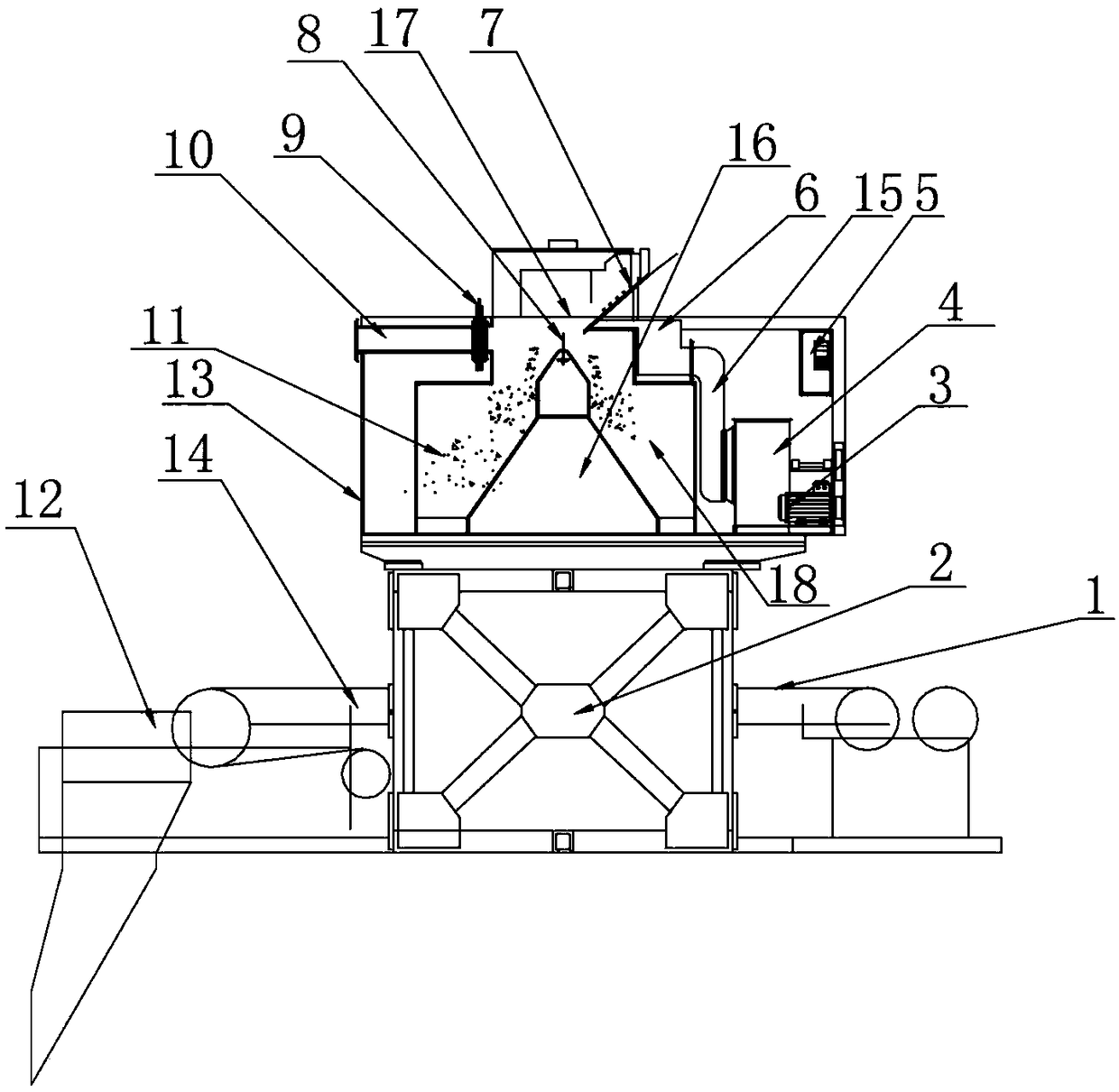

Embodiment 1

[0040] The wind power concentrator described in this embodiment is used for sorting all kinds of ores in the dressing plant, see figure 1, including tailings belt conveyor 1, bracket 2, motor 3, fan 4, frequency converter 5, air chamber 6, feeding regulating plate 7, material distribution regulating plate 8, grid 9, dust removal connecting pipe 10, concentrate buffer bin 11. Hopper 12, machine body 13, concentrate belt conveyor 14, air inlet pipe 15, conical distribution hopper 16, sorting chamber 17 and tailings buffer bin 18, the lower part of the body 13 is provided with a bracket 2, the body 13 A motor 3 is arranged inside, the motor 3 is connected to the fan 4 shaft, the motor 3 is connected to the frequency converter 5, the air outlet of the fan 4 communicates with the air chamber 6 through the air inlet pipe 15, and the air chamber 6 is located at One side of the sorting chamber 17, the grid 9 is located on the other side of the sorting chamber 17, the grid 9 is located...

Embodiment 2

[0057] The wind power concentrator described in this embodiment is used for waste recycling, including a tailings belt conveyor 1, a bracket 2, a motor 3, a fan 4, a frequency converter 5, an air chamber 6, a feeding adjustment plate 7, and a material distribution adjustment plate 8 , Grid 9, dust removal connecting pipe 10, concentrate buffer bin 11, hopper 12, body 13, concentrate belt conveyor 14, air inlet pipe 15, conical sub-hopper 16, separation chamber 17 and tailings buffer bin 18.

[0058] Compared with Embodiment 1, for the description of the structure of the wind-force concentrator in this embodiment, the similarities will not be repeated.

[0059] The use case 7 described below is a supplementary description of the second embodiment.

[0060] Scenario 7: Sorting and recycling of waste electronic devices

[0061] The resources that can be recovered from waste electronic devices mainly include inorganic materials and organic materials. Inorganic materials include ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com