Method for filling goaf by gangue

A goaf and gangue technology, which is applied in the direction of filling, mining equipment, earth cube drilling and mining, etc., can solve the problems of complex technology, many equipment, high cost, etc., and achieve the reduction of land occupation and pollution, reduction of lifting costs, and huge economic Effects of benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

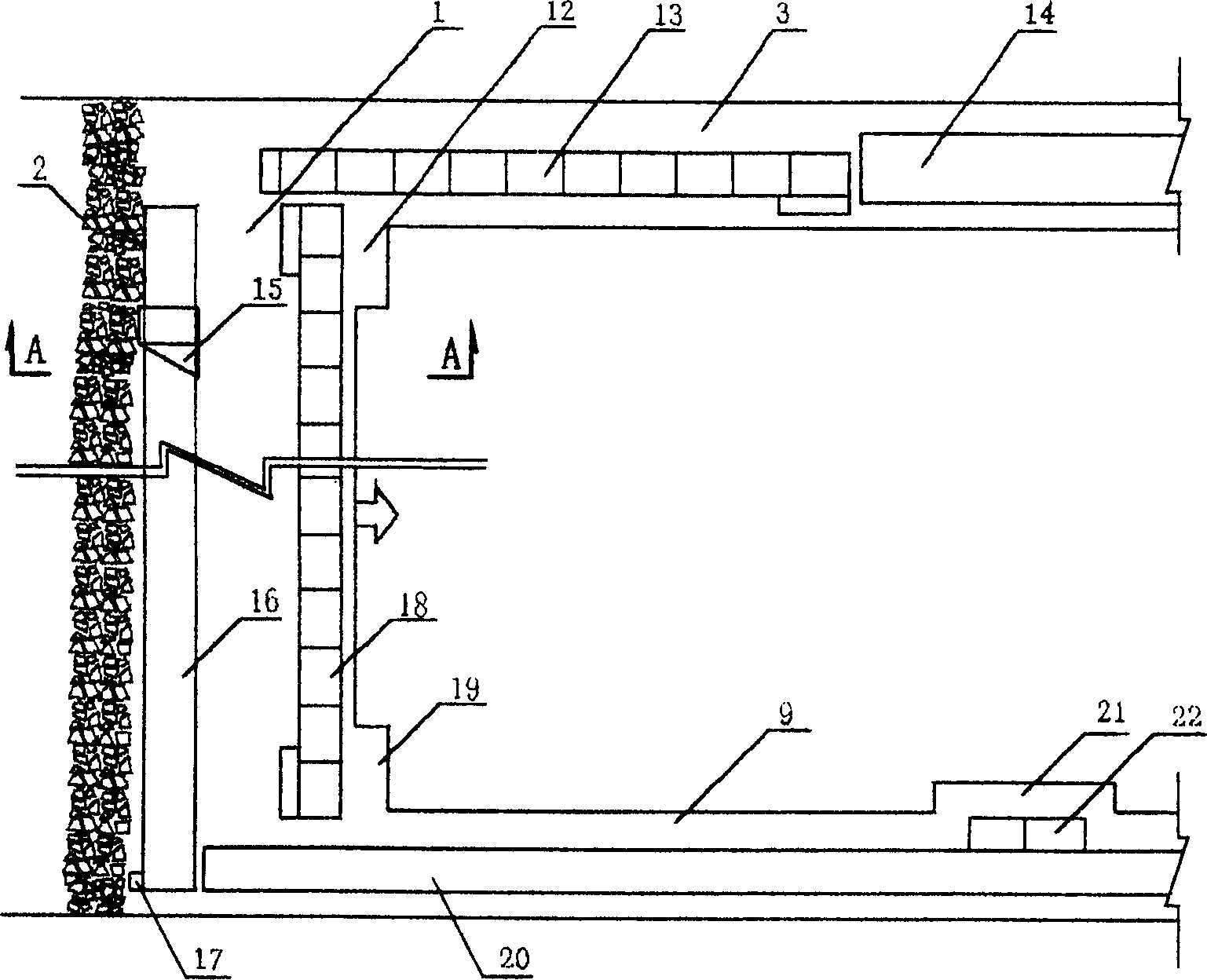

[0024] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0025] The method for filling the mined-out area with gangue of the present invention adopts the following technical measures:

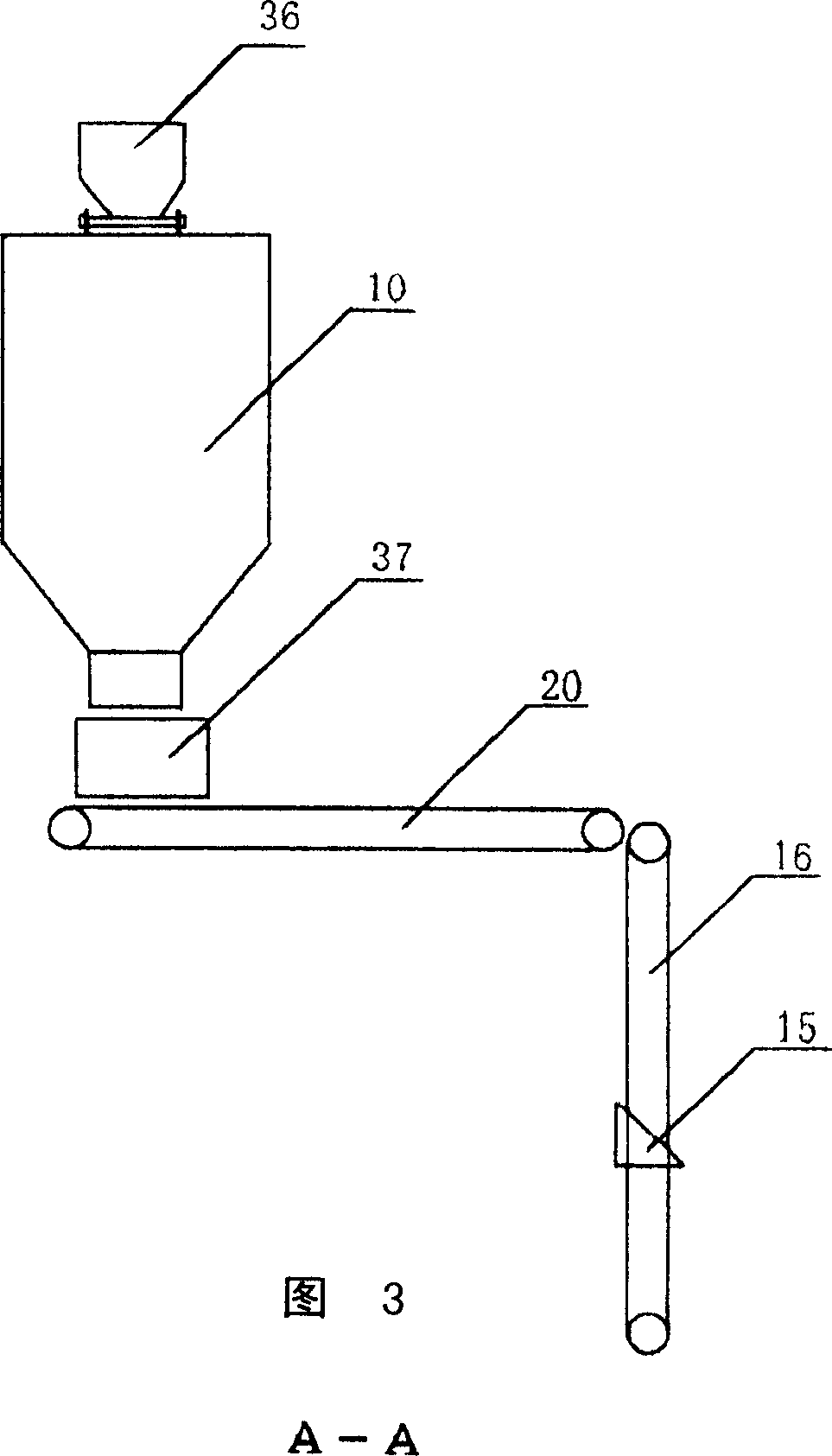

[0026] ① Build gangue bins (10) outside the mining face (1) to store gangue transported from underground or above the well.

[0027] ② Install the gangue belt conveyor (20) in the lane (9) on the mining face to transfer the gangue to the top of the mining face.

[0028] ③ The mining face (1) is supported by a bracket with a rear probe beam to reserve space for conveying and filling gangue.

[0029] 4. install a small belt conveyor (16) on one side of the gob in the mining face and under the back probe beam of the support.

[0030] 5. Install gangue unloading trolley (15) on small belt conveyor (16), unload gangue to goaf with unloading gangue trolley (15).

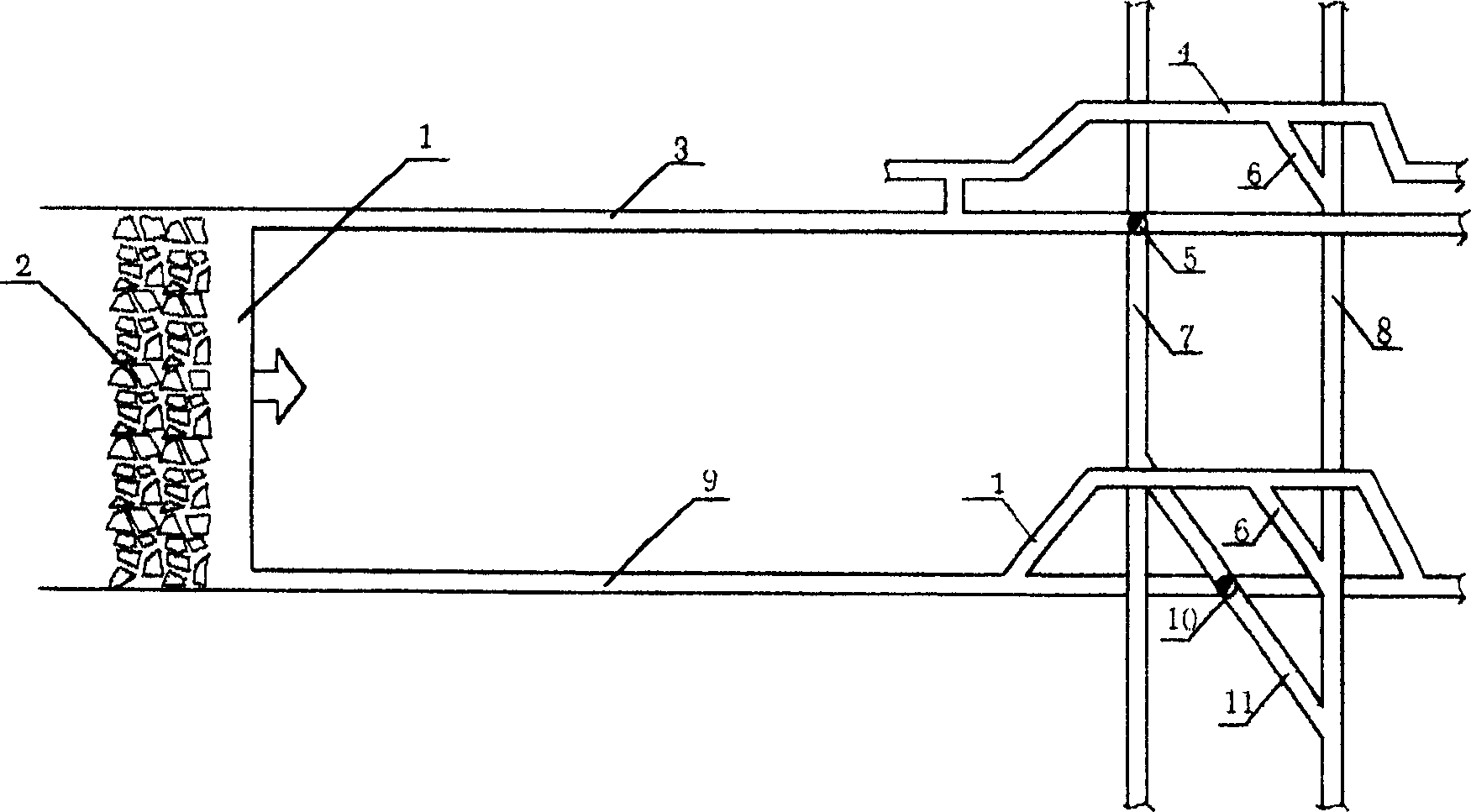

[0031] exist figure 1 shows the roadway layout of gangue fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com