Dust removal method for waste rock smashing in underground coal mine chamber

A chamber and gangue technology, which is applied in the field of dust reduction and operation chamber dust removal, can solve problems such as unsatisfactory effect, dust damage to workers, and difficulty in dust collection, and achieves significant economic benefits and promotion value, and is simple and easy to operate. The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

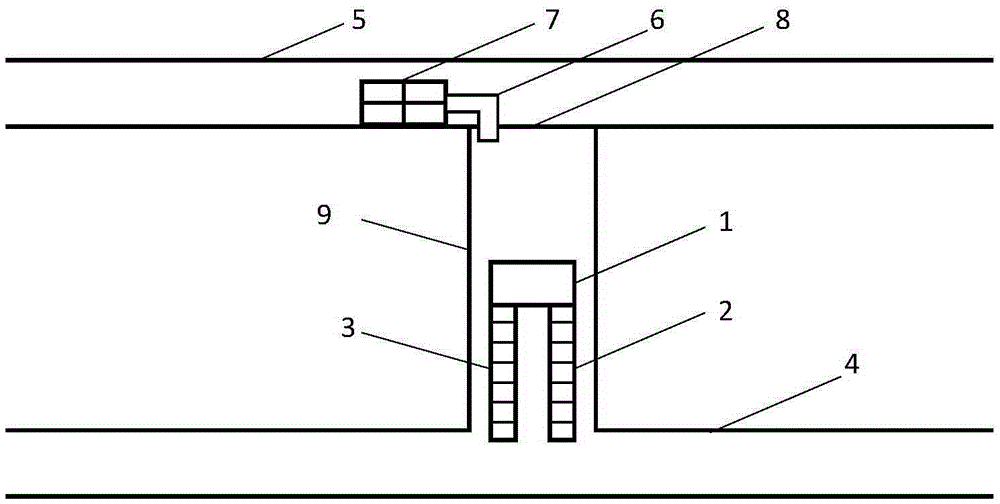

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] The dedusting method of gangue crushing in the coal mine underground chamber of the present invention, the specific steps are as follows:

[0018] a. The crushing chamber 9 connecting the air inlet lane 4 and the air return lane 5 is constructed between the air inlet lane 4 and the air return lane 5;

[0019] b. Install an exhaust fan 7 in the air return lane 5, so that the air duct 6 of the exhaust fan 7 is connected with the crushing chamber 9;

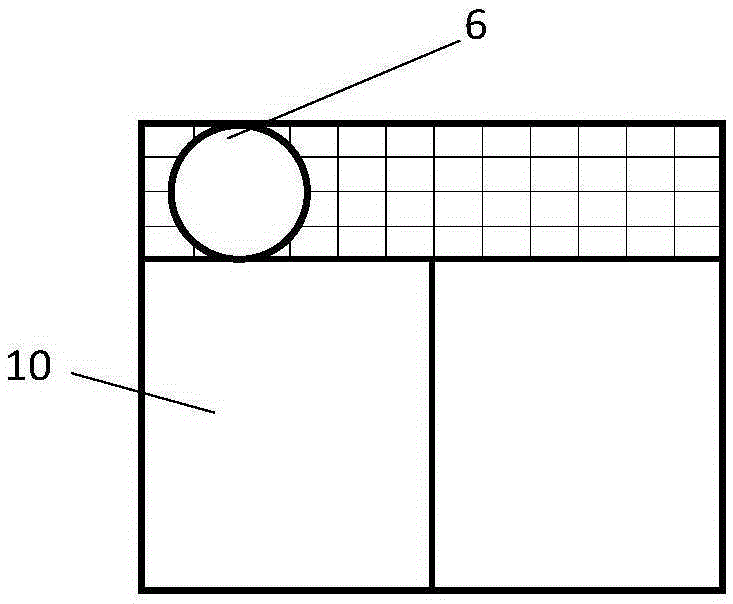

[0020] c. Install an adjusting door 8 on the side where the crushing chamber 9 is connected to the return air lane 5; Hole, air duct 6 is closely combined with circular hole, and the bottom is the left and right sliding door 10 that cooperates with upper part.

[0021] d. Install a crushing machine 1 in the crushing chamber 9, and the side where the crushing chamber 9 is connected to the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com