Integrated house

A technology for integrating houses and roof panels, applied in the direction of architecture and building structure, can solve the problems of single building structure, complex overall construction process, etc., achieve thin thickness, simple and fast assembly operation, excellent thermal insulation, sound insulation and energy-saving structure. effect of material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

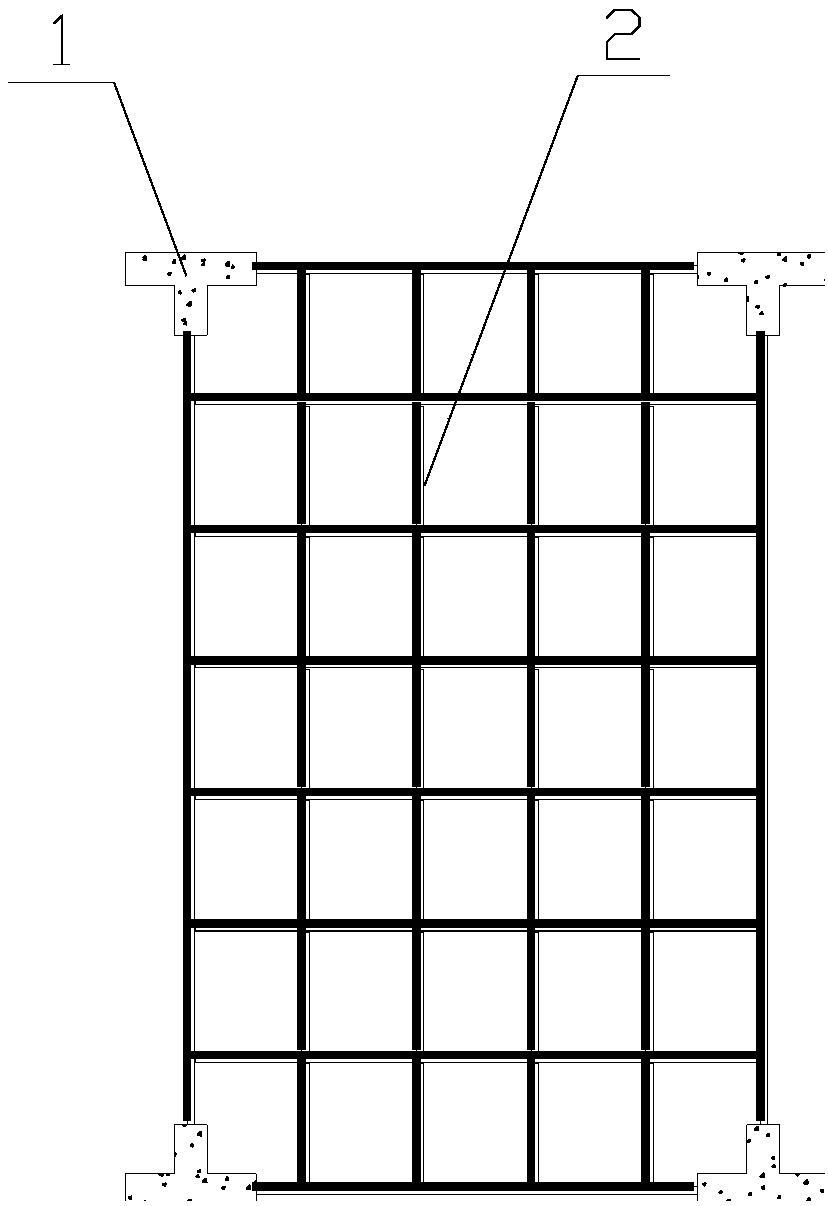

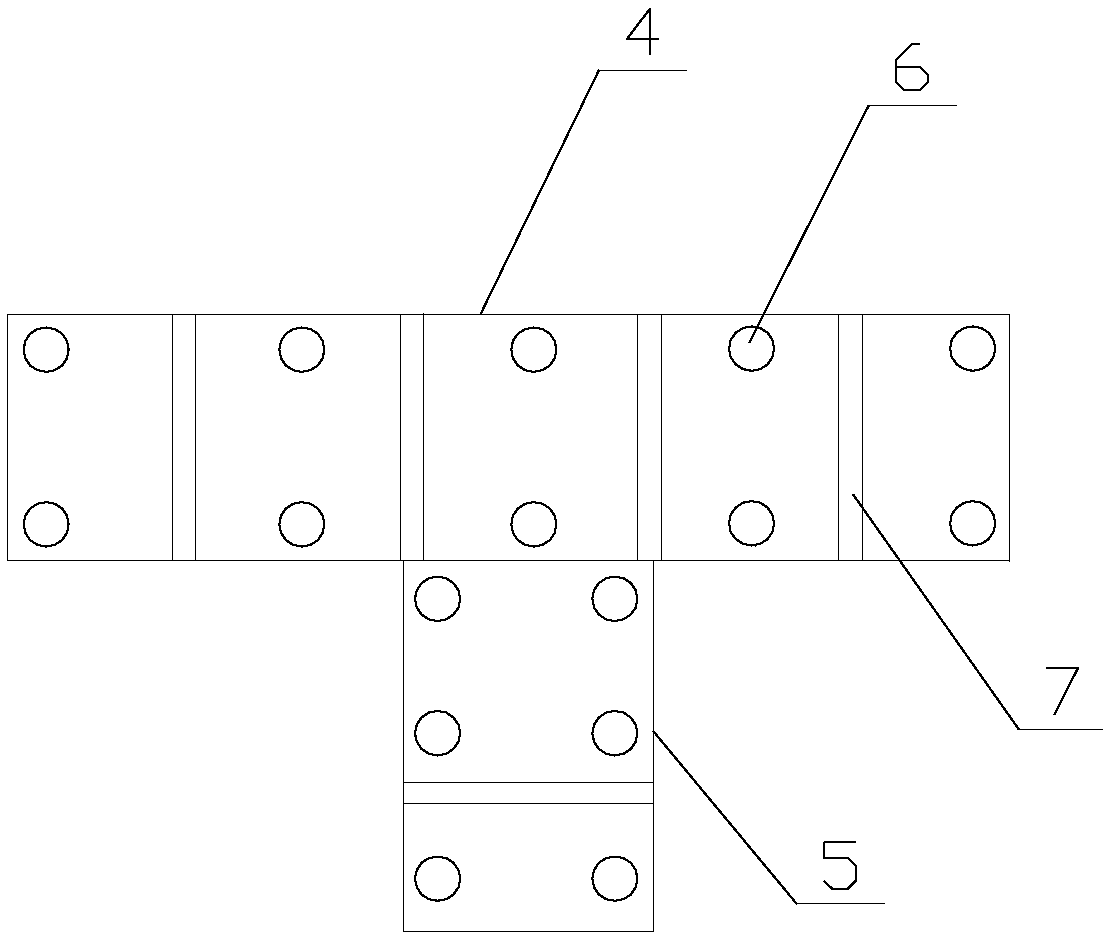

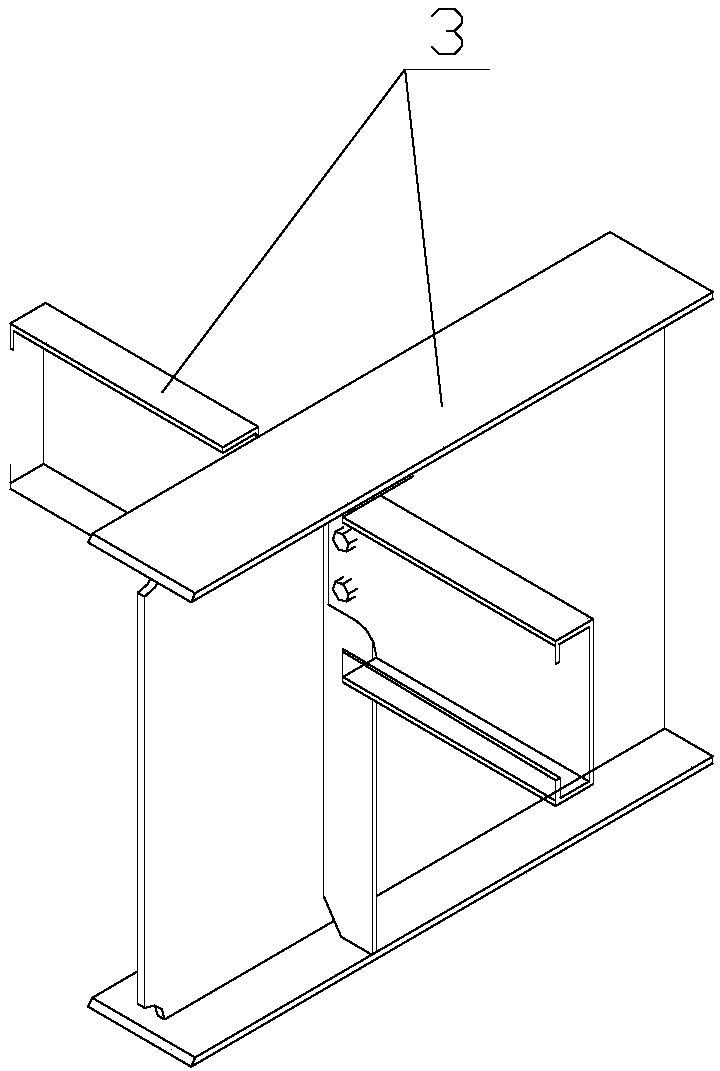

[0032] Such as Figures 1 to 11 As shown, an integrated house includes a light steel frame 9, which is assembled into a multi-layer structure aligned up and down, and the four corners of the light steel frame 9 are provided with support columns 10, and each layer of light steel frame 9 is The floor system and load-bearing wall 11 are provided, and the exterior wall system is installed around the light steel skeleton 9. The bottom of the light steel skeleton 9 is a building foundation frame 12, and the outer edge of the building foundation frame 12 is provided with a building skeleton guide rail 13, and the building foundation frame 12 also edge connectors 14 are provided;

[0033] Roof, the roof is set on the top of the light steel skeleton 9, the roof is composed of roof frame 15 and roof panel 16, and a photovoltaic power generation system and a photovoltaic heating system are also installed on the roof;

[0034] Floor-to-floor system, the floor-to-floor system includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com