Hierarchical synchronous hydraulic jacking process for large-tonnage ocean engineering structure

A technology for marine engineering and structures, applied in the direction of lifting devices, etc., can solve the problems of increasing the construction period of deck sheets, reducing the utilization rate of the site, and low hoisting efficiency of cranes, etc. The effect of a small stabilizing factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

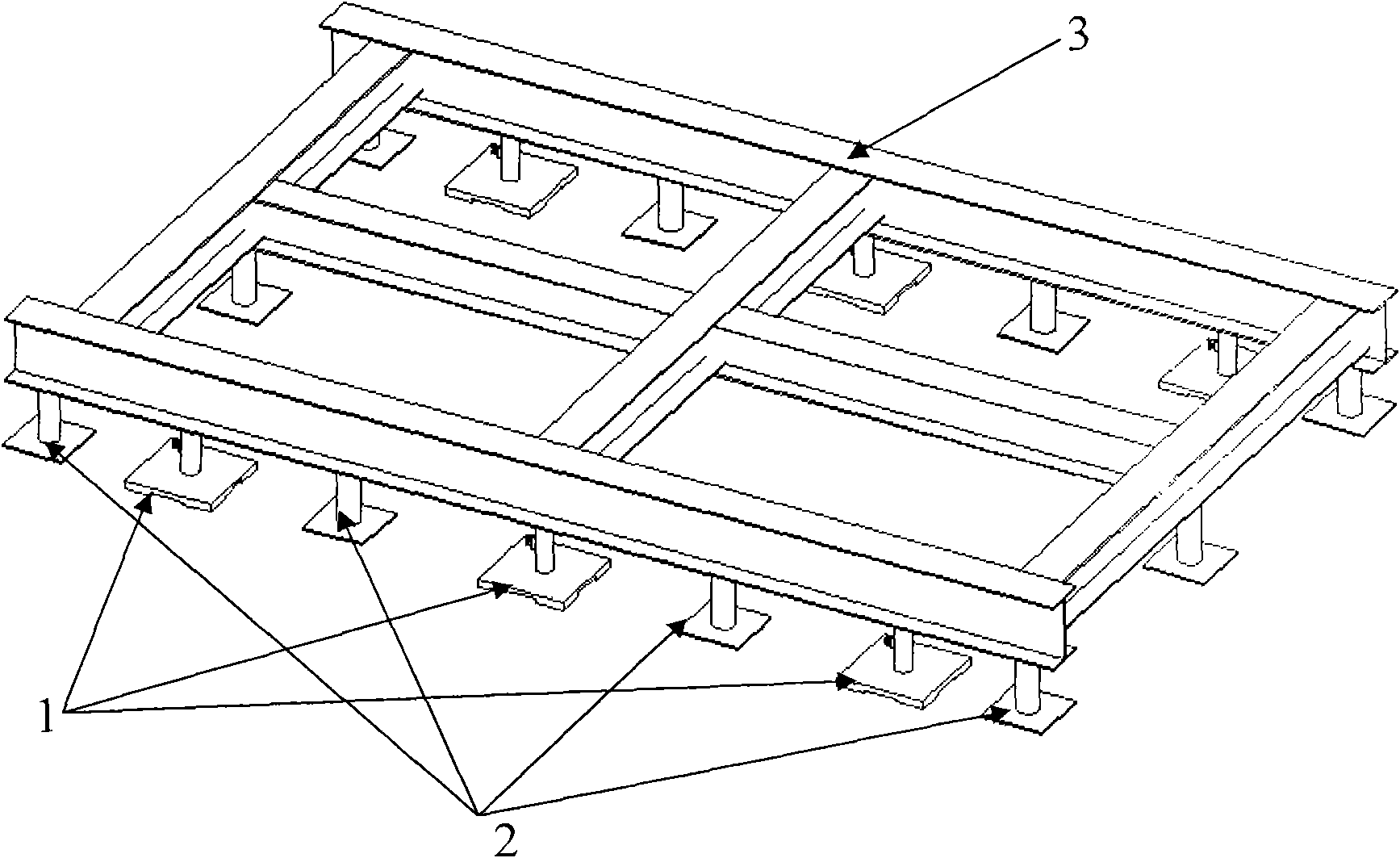

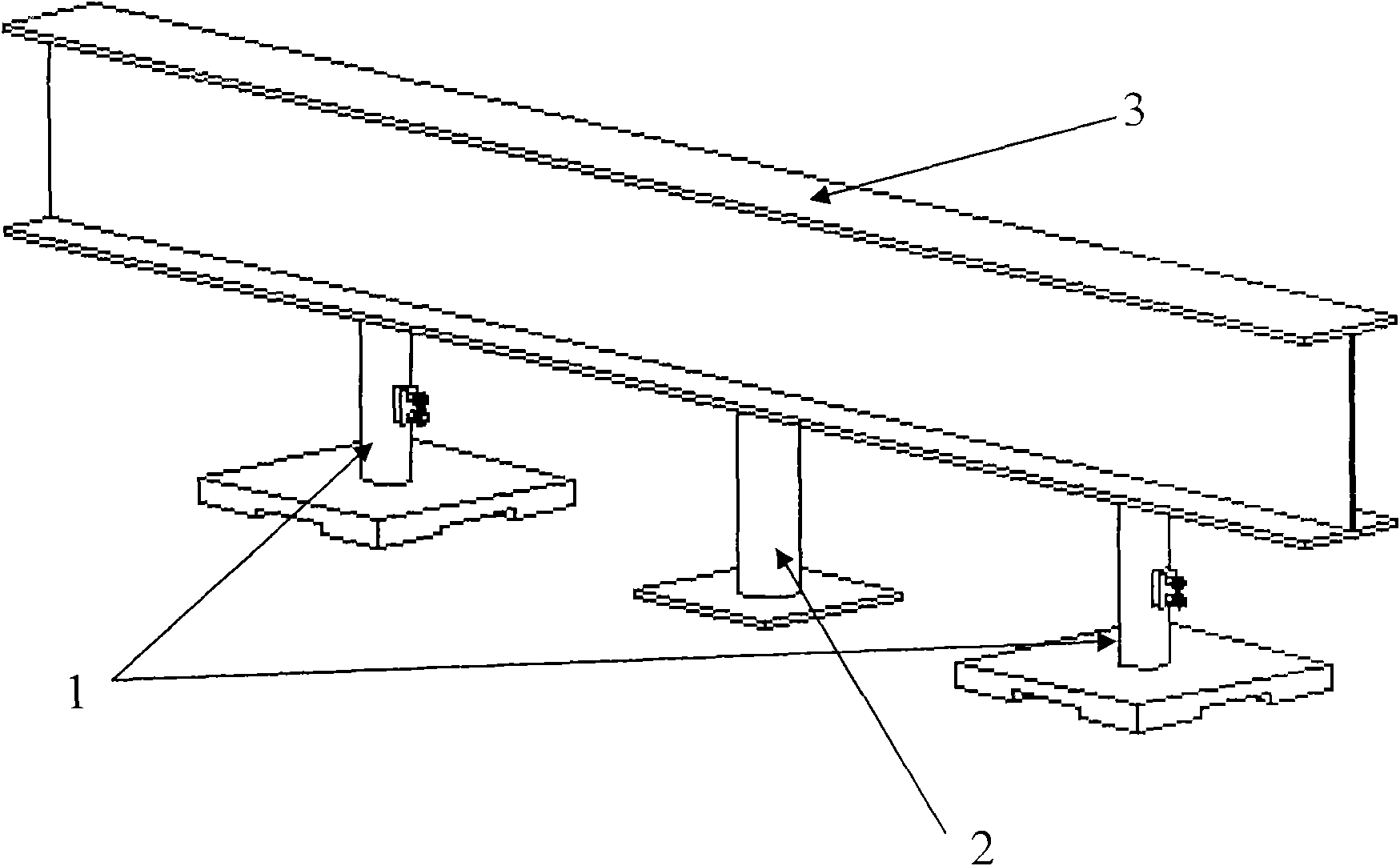

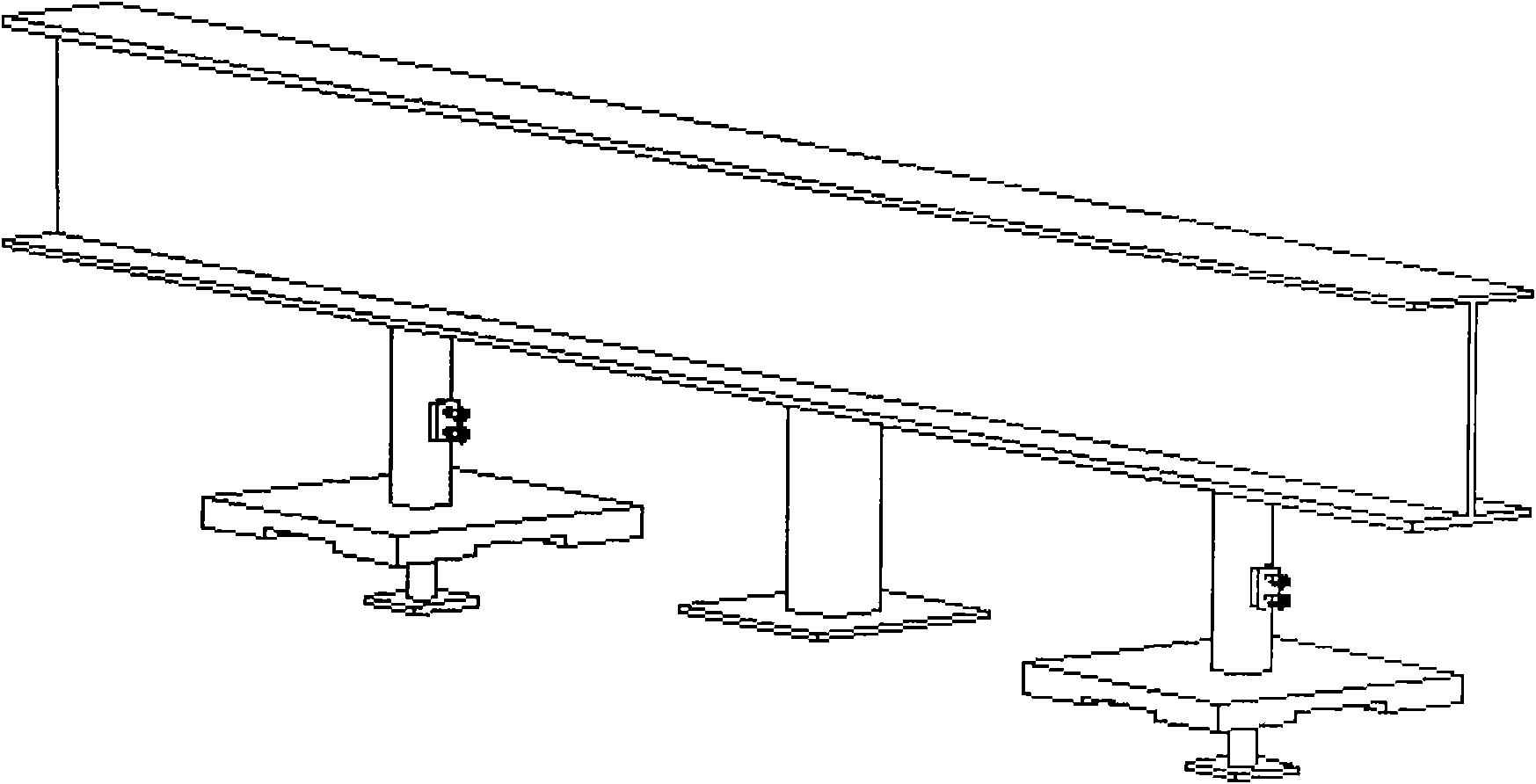

[0036] Such as figure 1 , figure 2 As shown, in the present invention, after the site prefabrication is completed, the deck piece is lifted by a graded synchronous hydraulic jacking system and then transported by a flatbed truck. The process is divided into the following steps:

[0037] Step 1: Arrange several hydraulic jacks 1 and several temporary protection supports 2 evenly under the structure, and connect the synchronous oil pump and hydraulic jack 1 through oil pipes;

[0038] (1) According to the characteristics of the structure-deck piece 3, through calculation, determine the number of jacks 1 and the location of jacks 1, as well as the number and location of temporary protective supports 2, and combine several hydraulic jacks 1 and temporary protective supports 2. According to the calculation, the structure is evenly arranged under the structure; then, the hydraulic jack 1 is connected and debugged with the synchronous oil pump through the oil pipe.

[0039] (2) In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com