Precast beam precise lifting device and method thereof

A lifting device and prefabricated beam technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of reserved holes, high hoisting costs, dense steel bars, etc., to ensure safety and reliability, use and Simple and convenient operation, simple and precise hoisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

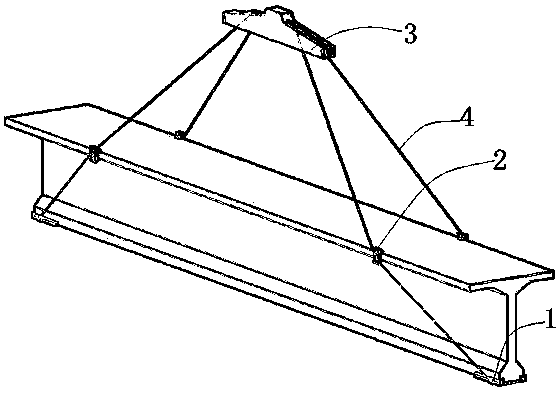

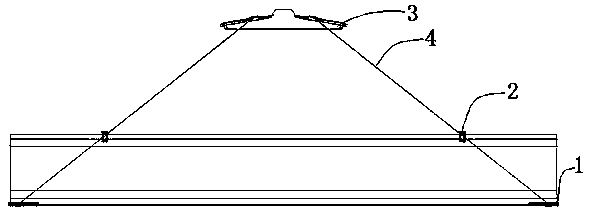

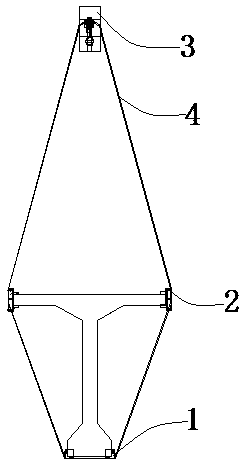

[0046] This embodiment provides a prefabricated beam precise lifting device, such as Figure 1-7 As shown, the device is used for hoisting prefabricated beams, including supporting parts 1, buffer plates 2, pole beams 3 and steel wire ropes 4; during hoisting, supporting parts 1 are arranged at the corners of the bottom of prefabricated beams, and buffer plates 2 is set on the flange of the prefabricated beam, while the shoulder beam 3 is located at the lifting point, and the steel wire rope 4 is wound and tightened on the supporting member 1, the buffer plate 2 and the shoulder beam 3, thereby hoisting the prefabricated beam.

[0047] The advantage is that the device is simple to manufacture, can be recycled, and is suitable for different beam lengths. At the same time, the hoisting is simple and precise. The construction personnel can complete the precise hoisting only through simple operations, completely solving the problem of "top-heavy" when hoisting beams. Phenomenon. ...

Embodiment 2

[0060] This embodiment is similar to the first embodiment, the difference lies in the structure of the support plate 13 and the position adjustment device 5 of the shoulder beam 3 .

[0061] Specifically, such as Figure 1-7 As shown, the positioning device 5 also includes an elastic member 53, the elastic member 53 includes a fixed end and a movable end, the elastic member 53 is connected with the other end of the first slider 11 or the second slider 31 through the movable end, and its main The function is to buffer or drive the sliding of the first slider 11 or the second slider 31 on the chute. In this embodiment, the elastic member 53 is a spring.

[0062] More specifically, for a better user experience, the specific structure of the positioning device 5 in this embodiment is provided. Specifically, the elastic member 53 in the positioning device 5 is a spring, and the positioning assembly 51 includes bolts, nuts and threaded boxes. In terms of the supporting member 1, ...

Embodiment 3

[0066] Such as Figure 8 As shown, this embodiment provides a method for precise lifting of prefabricated beams, which is applied to precise lifting devices for prefabricated beams, including:

[0067] S1. Installation of supporting member 1: Install supporting member 1 at the four end corners of the beam rib of the prefabricated beam, and attach the limiting plate 12 and the supporting plate 13 to the beam rib;

[0068] S2. Position adjustment of the first slider 11: Pass the two steel wire ropes 4 under the two ends of the beam rib of the prefabricated beam respectively, and lock them in the slot 6 of the first slider 11 of the two supporting parts 1 at the same end of the beam rib Firstly, adjust the position of the first slider 11 on the supporting member 1 according to the length of the prefabricated beam and use the adjustment ruler, and then position the first slider 11 through the positioning assembly 51;

[0069] S3. Installation of the buffer plate 2: Determine the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com