Preparation method of high-temperature-resisting filtration-loss reducer for drilling fluid

A filtrate reducer and anti-high temperature technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of drilling fluid flocculation and stratification, malignant fluid loss, stuck pipe, etc., and achieve temperature and salt resistance Outstanding calcium intrusion ability, good adsorption performance, and the effect of reducing filtration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

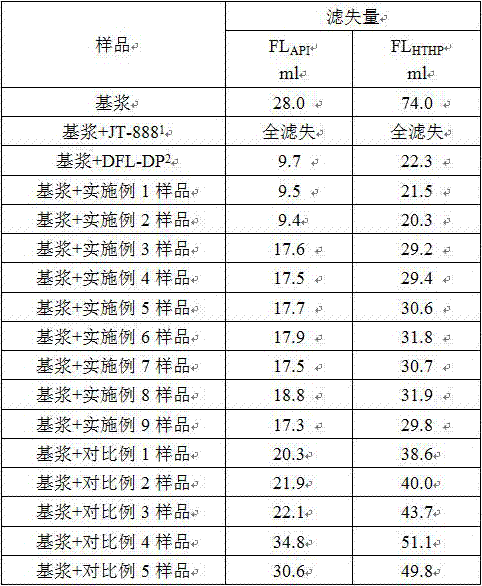

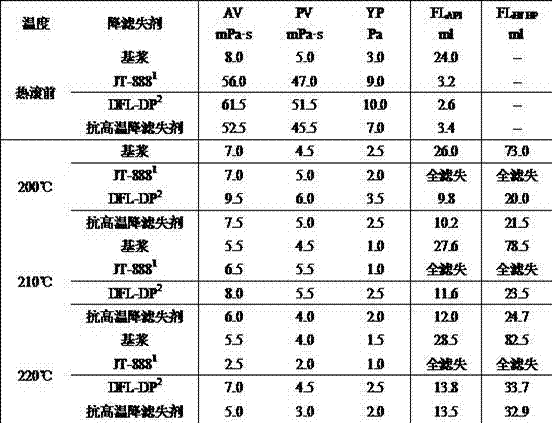

Examples

Embodiment 1

[0011] Mix 35 parts of 2-acrylamide-2-methylpropanesulfonic acid AMPS and 25 parts of acrylic acid AA, add appropriate amount of potassium hydroxide to adjust its pH to 7~8, add 32 parts of acrylamide AM and 8 parts of N-ethylene Base pyrrolidone NVP and stir well. Add 0.2 parts of disodium edetate to the mixed monomer solution, and transfer the mixed solution into the reaction kettle after completely dissolving. Add 1 part of chitosan-Mn-bentonite material while stirring, then fill with nitrogen and heat up. press n 过硫酸钠 :n 亚硫酸钠 =1.2:1 Weigh 0.3 parts of the monomer mass to make a solution, slowly add it into the reactor alternately, keep the reaction temperature in the reactor at 30°C and stir at 300r / min for 8 hours, when the liquid viscosity in the reactor reaches 500cp above, and when the solution turns light yellow, the material is discharged and cooled to obtain a high temperature resistant fluid loss reducer.

[0012] The preparation method of the above-mentioned c...

Embodiment 2

[0021] Mix 42 parts of 2-acrylamide-2-methylpropanesulfonic acid AMPS and 30 parts of acrylic acid AA, add appropriate amount of potassium hydroxide to adjust its pH to 7~8, add 25 parts of acrylamide AM and 7 parts of N-vinyl Pyrrolidone NVP was stirred well. Add 0.2 parts of disodium edetate to the mixed monomer solution, and transfer the mixed solution into the reaction kettle after completely dissolving. Add 2 parts of chitosan-Mn-bentonite material while stirring, then fill with nitrogen and heat up. press n 过硫酸钠 :n 亚硫酸钠 =1.2:1 Weigh 0.3 parts of the monomer mass to form a solution, slowly add it into the reactor alternately, keep the reaction temperature in the reactor at 35°C and stir at 300r / min for 8 hours, when the liquid viscosity in the reactor reaches 500cp above, and when the solution turns light yellow, the material is discharged and cooled to obtain a high temperature resistant fluid loss reducer.

Embodiment 3

[0023] Mix 45 parts of 2-acrylamide-2-methylpropanesulfonic acid AMPS and 25 parts of acrylic acid AA, add appropriate amount of potassium hydroxide to adjust its pH to 7~8, add 25 parts of acrylamide AM and 5 parts of N-vinyl Pyrrolidone NVP was stirred well. Add 0.2 parts of disodium edetate to the mixed monomer solution, and transfer the mixed solution into the reaction kettle after completely dissolving. Add 2 parts of chitosan-Mn-bentonite material while stirring, then fill with nitrogen and heat up. press n 过硫酸钠 :n 亚硫酸钠 =1.2:1 Weigh 0.3 parts of the monomer mass to make a solution, slowly add it into the reactor alternately, keep the reaction temperature in the reactor at 40°C and stir at 300r / min for 8 hours, when the liquid viscosity in the reactor reaches 500cp above, and when the solution turns light yellow, the material is discharged and cooled to obtain a high temperature resistant fluid loss reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com