Preparation method of AA (acrylic acid)/AM (acrylamide)/AMPS (2-acrylamido-2-methylpropane sulfonic acid)/MAH (maleic anhydride)-beta-CD (cyclodextrin) quaternary oil displacement agent

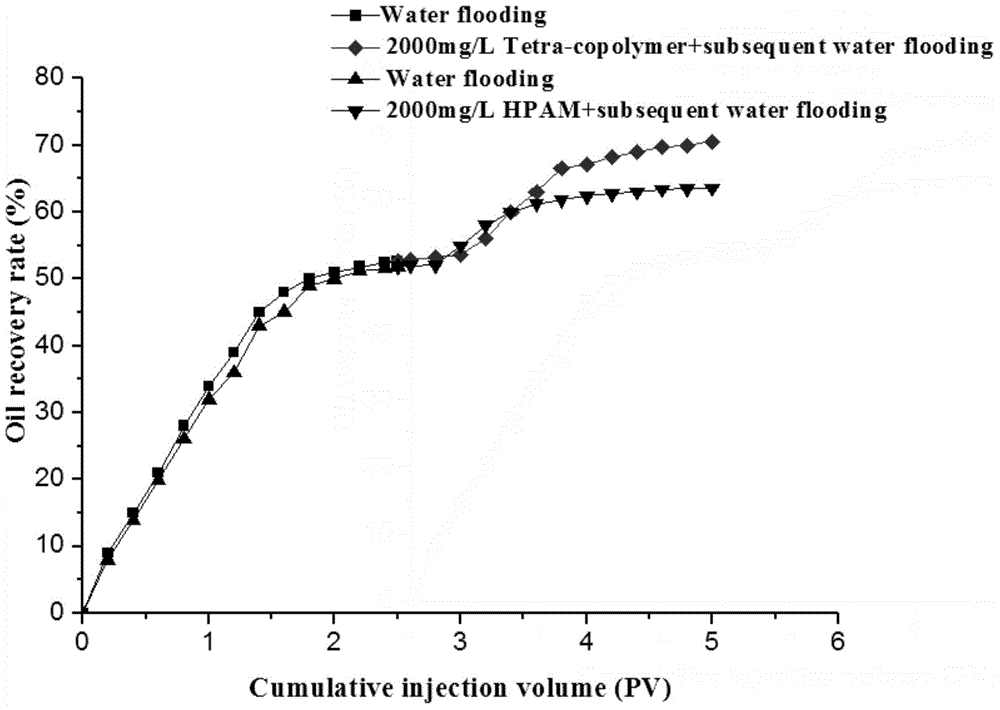

An oil displacement agent, disodium ethylenediamine tetraacetate technology, applied in the field of preparation of AA/AM/AMPS/MAH-β-CD quaternary oil displacement agent, can solve the problem of complex and costly modification of cyclodextrin substances Advanced problems, to achieve the effect of enhanced oil recovery, low cost, and remarkable oil displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of AA / AM / AMPS / MAH-β-CD quaternary oil displacement agent of the present invention is as follows:

[0030] (1) Prepare modified cyclodextrin, dissolve β-cyclodextrin and maleic anhydride in DMF, the weight ratio of cyclodextrin and maleic anhydride is 3:6, and the weight-to-volume ratio of cyclodextrin and DMF is 3: 40g / ml; then stirred and reacted at 70°C for 15 hours, cooled the reaction product to room temperature and added chloroform to form a white precipitate, filtered the precipitate and washed it with acetone, and dried the filter cake in an oven to obtain maleic anhydride modified β-cyclodextrin;

[0031] (2) Add acrylic acid, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid and maleic anhydride-β-cyclodextrin prepared in step (1) into the reactor, react under nitrogen protection, add Adjust the pH to 6-8 with sodium hydroxide, then add the initiator ammonium persulfate-sodium bisulfite and disodium ethylenediaminetetraacetic acid (E...

Embodiment 2

[0038] The preparation method of AA / AM / AMPS / MAH-β-CD quaternary oil displacement agent of the present invention is as follows:

[0039] (1) Prepare modified cyclodextrin, dissolve β-cyclodextrin and maleic anhydride in DMF, the weight ratio of cyclodextrin and maleic anhydride is 8:3, and the weight-to-volume ratio of cyclodextrin and DMF is 8:20g / ml; then stirred and reacted at 90°C for 5 hours, cooled the reaction product to room temperature and added chloroform to form a white precipitate, filtered the precipitate and washed it with acetone, and dried the filter cake in an oven to obtain maleic anhydride modified β-cyclodextrin;

[0040] (2) Add acrylic acid, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid and maleic anhydride-β-cyclodextrin prepared in step (1) into the reactor, react under nitrogen protection, add Adjust the pH to 7-9 with sodium hydroxide, then add the initiator ammonium persulfate-sodium bisulfite and disodium ethylenediaminetetraacetic acid (EDT...

Embodiment 3

[0047] The preparation method of AA / AM / AMPS / MAH-β-CD quaternary oil displacement agent of the present invention is as follows:

[0048] (1) Prepare modified cyclodextrin, dissolve β-cyclodextrin and maleic anhydride in DMF, the weight ratio of cyclodextrin and maleic anhydride is 5.68:4.9, and the weight-to-volume ratio of cyclodextrin and DMF is 5.68:30g / ml; then stirred and reacted at 80°C for 10 hours, cooled the reaction product to room temperature and added chloroform to form a white precipitate, filtered the precipitate and washed with acetone, dried the filter cake in an oven to obtain maleic anhydride modified β-cyclodextrin;

[0049] (2) Add acrylic acid, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid and maleic anhydride-β-cyclodextrin prepared in step (1) into the reactor, react under nitrogen protection, add Adjust the pH to 8-10 with sodium hydroxide, then add the initiator ammonium persulfate-sodium bisulfite and disodium ethylenediaminetetraacetic acid (ED...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com