Double electron type polymerizable surfactant monomer, and preparation method and applications thereof

A surfactant, electronic technology, applied in the field of oilfield chemistry, can solve the problems of poor sand suspension ability, low cost, low yield and purity, high cost of fracturing fluid, low cost, good viscoelasticity and temperature and salt resistance. , Solve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

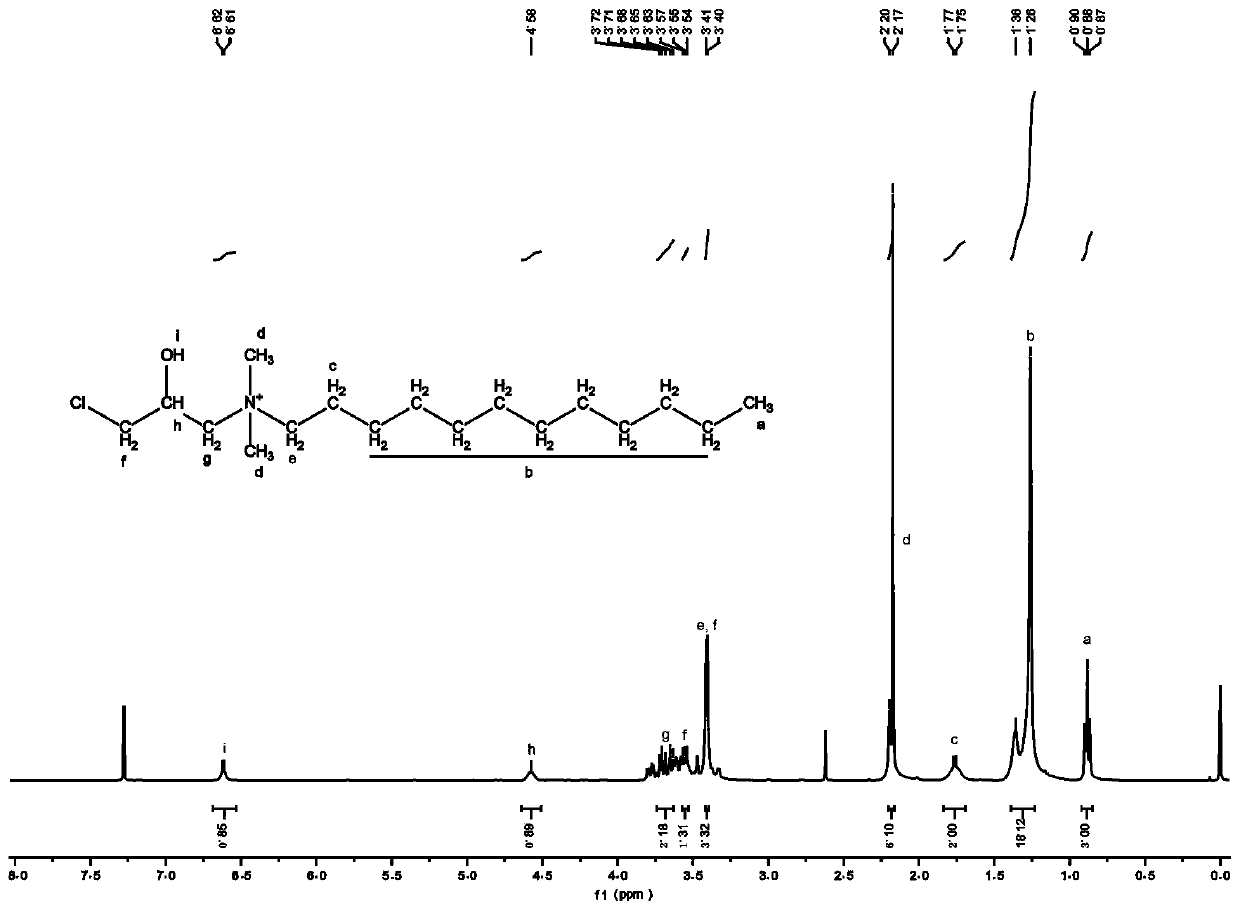

[0030] First, 100 mmol of dodecyl dimethyl tertiary amine was dissolved in ethanol, then 120 mmol of 37% hydrochloric acid was added to the round bottom flask, and stirred at room temperature for 5 min to completely dissolve the hydrochloric acid into the solution. Then, 200 mmol of epichlorohydrin was added into the flask, and the temperature was raised to 55° C. for 6.0 hours of reaction. After the reaction is completed, the ethanol and the remaining epichlorohydrin are removed by rotary evaporation, and finally a light yellow viscous paste is obtained, which is placed in a dry bottle for later use, and is recorded as EPT-12. The nuclear magnetic spectrum is as follows: figure 1 shown.

Embodiment 2

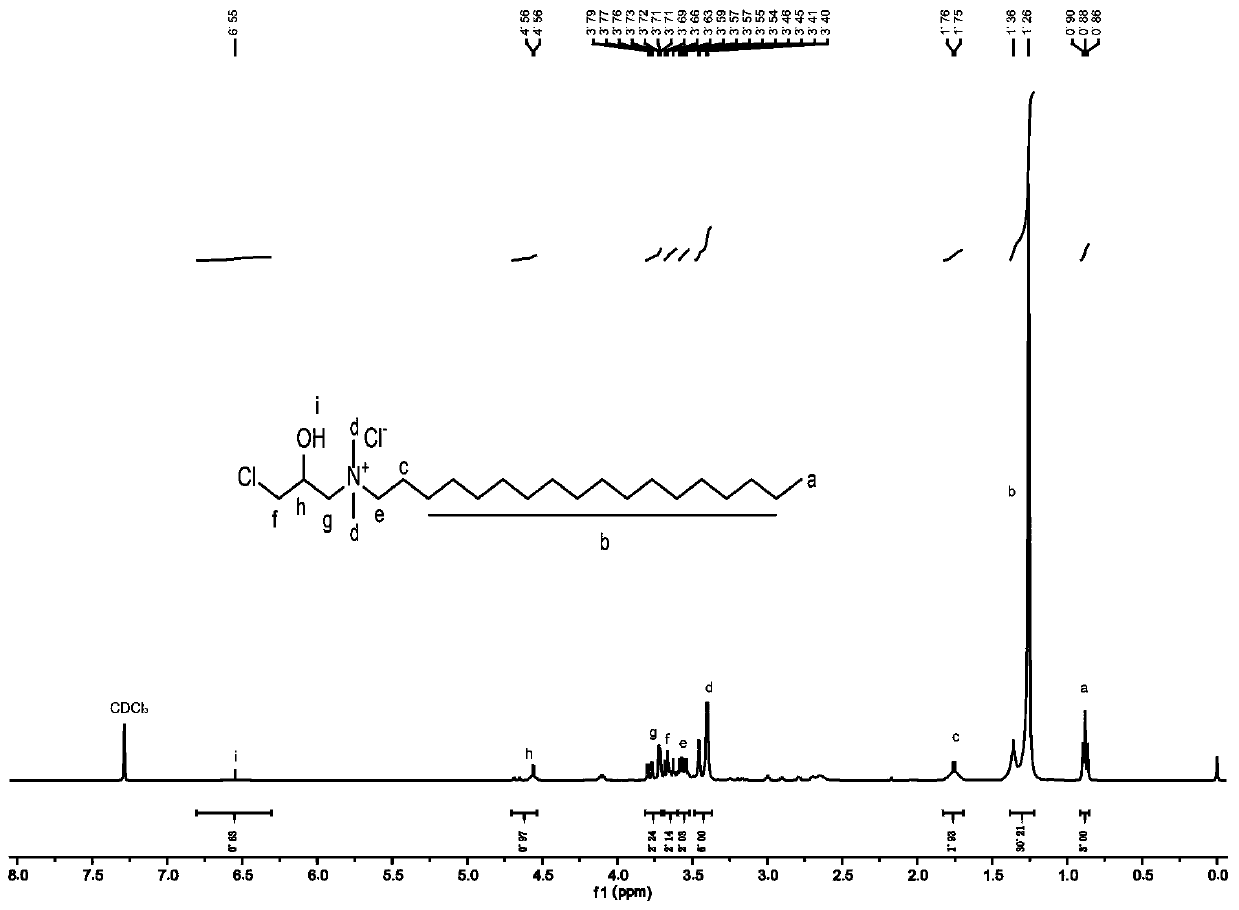

[0032] First, 100 mmol of octadecyl dimethyl tertiary amine was dissolved in ethanol, then 140 mmol of 37% hydrochloric acid was added to the round bottom flask, and stirred at room temperature for 10 min to completely dissolve the hydrochloric acid into the solution. Next, 160 mmol of epichlorohydrin was added into the flask, and the temperature was raised to 60° C. for 4.0 hours of reaction. After the reaction was completed, the ethanol and the remaining epichlorohydrin were removed by rotary evaporation, and finally a light yellow viscous paste was obtained, which was placed in a dry bottle for later use, recorded as EPT-18, and the nuclear magnetic spectrum was as follows: figure 2 shown.

Embodiment 3

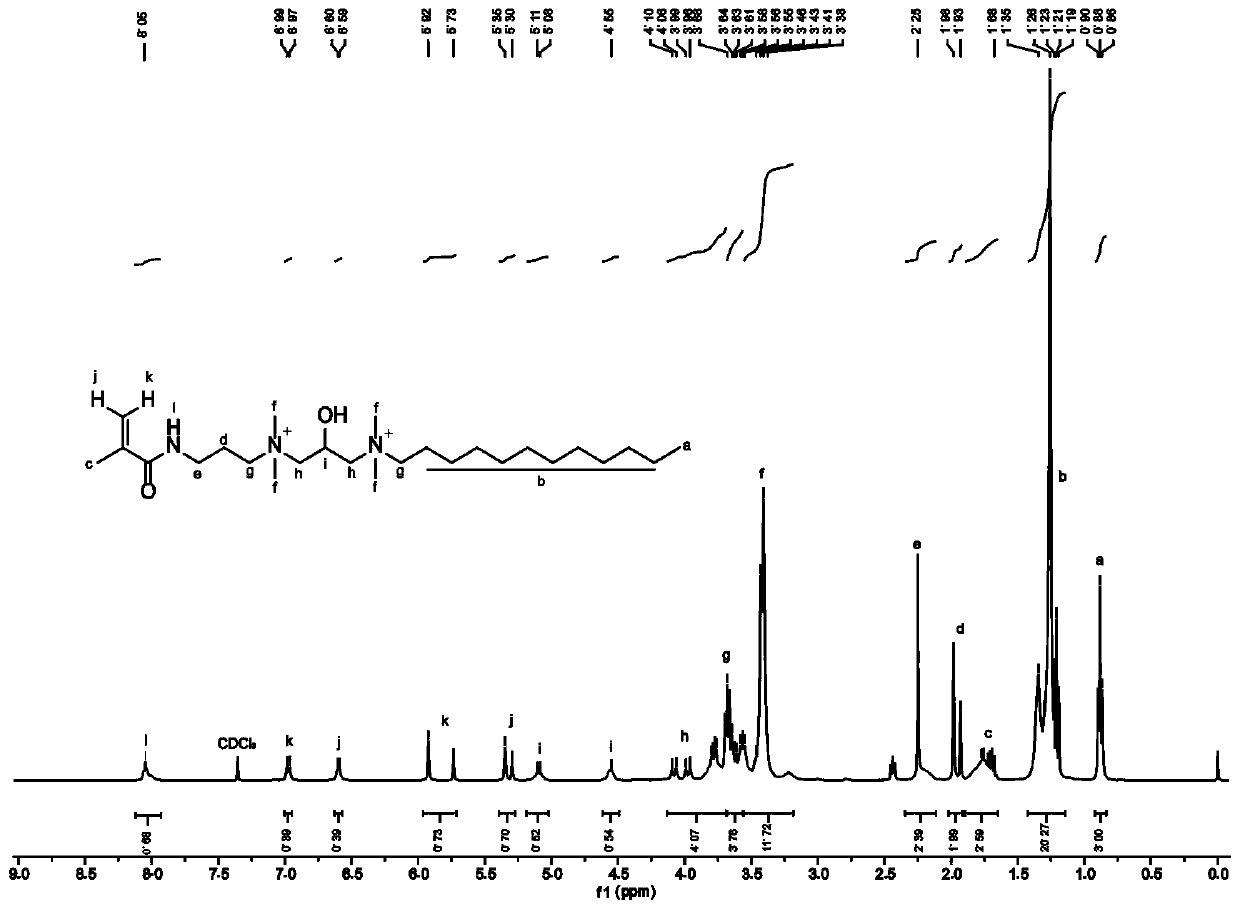

[0034] First, 100 mmol of EPT-12 and 120 mmol of N-dimethylaminopropyl methacrylamide were dissolved in ethanol, followed by a reaction at 55° C. for 10 h. After the reaction is finished, the solvent is removed by rotary evaporation, and a light yellow viscous liquid will be obtained, which is denoted as DMEPT-12, and the nuclear magnetic spectrum is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com