A kind of anti-high temperature delayed gel breaker and preparation method thereof

A gel breaker and anti-high temperature technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of short delay time and achieve the effects of slowing down the temperature rise, simple preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Based on this, the second aspect of the embodiment of the present invention provides a preparation method of a high-temperature resistant delayed gel breaker using nano-silica as the shell material. The preparation method uses orthosilicate as a precursor and adopts a sol-gel method Preparation of nano-silica-coated anti-high temperature delayed breaker. Specifically, the preparation method comprises: dispersing persulfate and / or peroxide and surfactant into absolute ethanol to obtain an absolute ethanol dispersion, and then adding orthosilicate and ammonia water to the absolute ethanol dispersion , react at a temperature of 0°C to 40°C for 0.5 to 12 hours, filter, wash and dry to obtain a high-temperature resistant compound with persulfate and / or peroxide as the core material and nano-silicon dioxide as the shell material. Delayed breaker.

[0033] The above preparation method has a simple process and is easy to control, and the obtained high-temperature delayed gel-b...

Embodiment 1

[0043] This embodiment provides a high temperature resistant delayed gel breaker with a core-shell structure using nano-silicon dioxide as the shell material and ammonium persulfate as the core material.

[0044] The preparation method of this high temperature resistant delayed gel breaker is as follows:

[0045] Disperse 1 g of ammonium persulfate and 0.5 g of polyvinylpyrrolidone into 0.1 liter of absolute ethanol to obtain an absolute ethanol dispersion, and then add 10 ml of NH 3 Ammonia water with a mass percentage of 25% to 28% and 6 ml of ethyl orthosilicate were reacted at 25° C. for 4 hours. After the reaction was completed, the crude product was obtained by filtration, and the crude product was washed and dried to obtain the high temperature resistant delayed breaker of this embodiment.

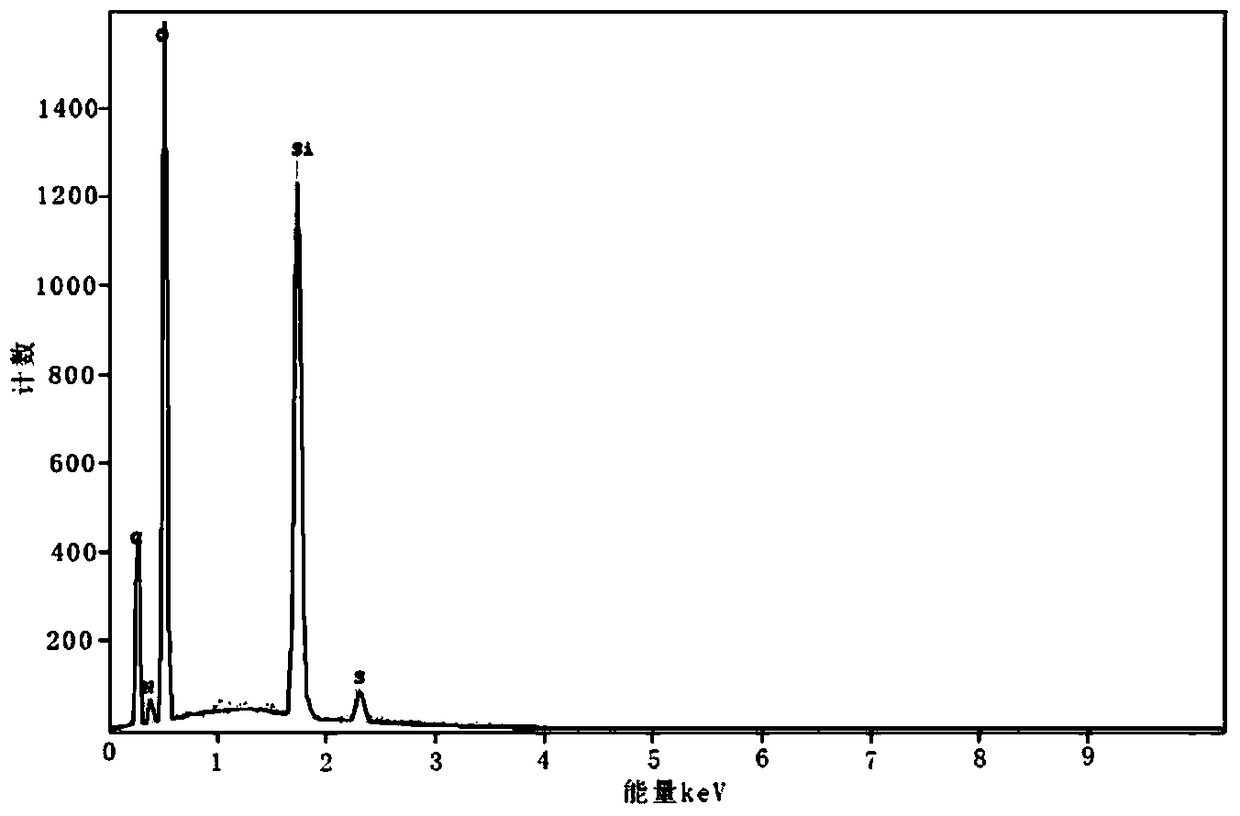

[0046] Depend on figure 1 It can be seen that the peak of sulfur element comes from the core of ammonium persulfate with core-shell structure, and the peak of silicon element come...

Embodiment 2

[0049] This embodiment provides a high temperature resistant delayed gel breaker with a core-shell structure using nano-silicon dioxide as the shell material and ammonium persulfate as the core material.

[0050] The preparation method of this high temperature resistant delayed gel breaker is as follows:

[0051] Disperse 4 grams of ammonium persulfate and 0.3 grams of polyvinylpyrrolidone into 0.2 liters of absolute ethanol to obtain an absolute ethanol dispersion, then add 50 ml of NH 3 Ammonia water with a mass percentage of 25% to 28% and 70 ml of ethyl orthosilicate were reacted at 20° C. for 8 hours. After the reaction was completed, the crude product was obtained by filtration, and the crude product was washed and dried to obtain the high temperature resistant delayed breaker of this embodiment.

[0052] The morphology of the high temperature resistant delayed breaker obtained in this example is basically the same as that in Example 1. The delayed breaker can remain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com