High temperature resistant organic zirconium crosslinking agent and preparation method thereof, a fracturing fluid jelly and preparation method thereof

A zirconium crosslinking agent, high temperature resistant technology, applied in the field of oil drilling, can solve the problems affecting the performance of the crosslinking agent, fast crosslinking speed, low solubility, etc., to achieve delayed crosslinking performance, stable jelly performance, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

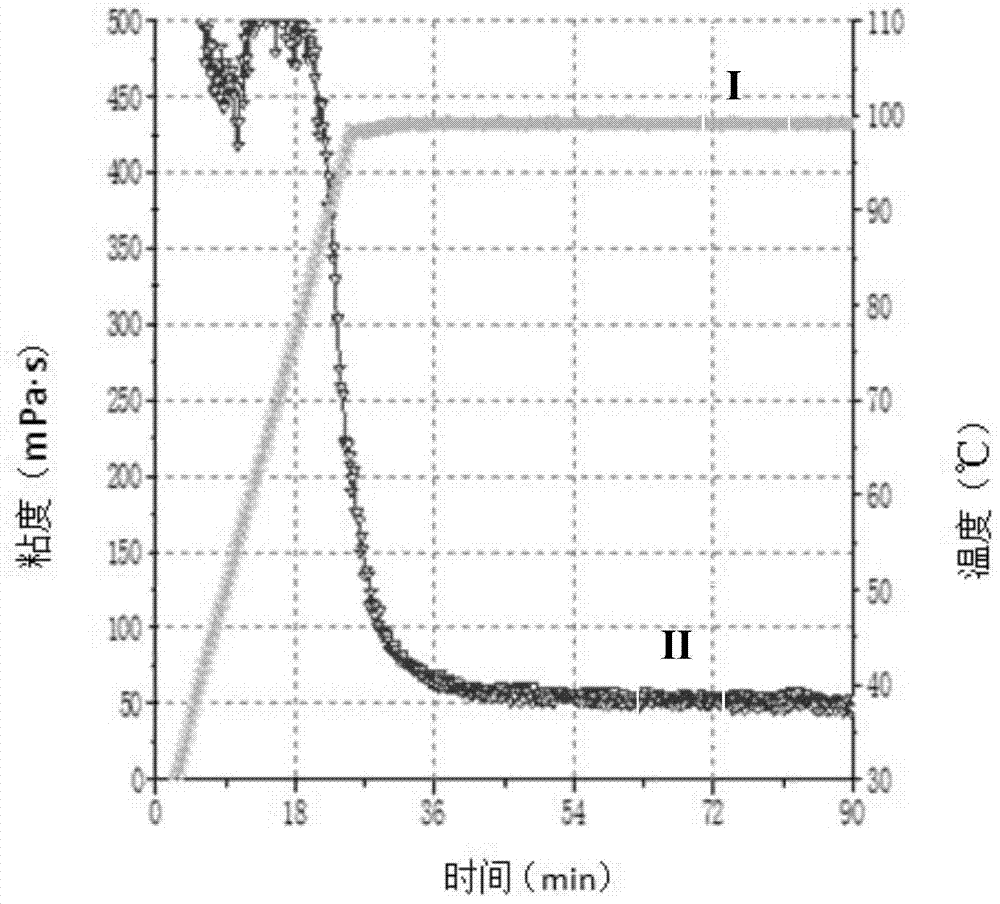

Embodiment 1

[0036] The mass percentage of each reaction raw material is water: glycerol: zirconium oxychloride: sodium hydroxide: lactic acid: sodium gluconate: N, N ~ methylenebisacrylamide: butyl phosphate = 50:15:5: 15:5:3:2:5.

[0037] (1) First add water into the reactor, and adjust the temperature of the reactor to 55°C, then add the solvent glycerol while stirring, and stir for 0.5h;

[0038] (2) Keep the temperature of the reaction kettle constant, add zirconium oxychloride into the kettle, stir to make it fully dissolved in the solvent, add NaOH to adjust the pH value to 8, and hydrolyze for 1 hour;

[0039] (3) After all the raw materials in the reactor are dissolved, adjust the temperature of the reactor to 80°C, add ligand lactic acid, sodium gluconate and cross-linking agent N,N-methylenebisacrylamide into the solution, and stir until completely Dissolve and heat complexation reaction for 2.5h;

[0040] (4) Raise the temperature of the reaction kettle to 90° C., add the hig...

Embodiment 2

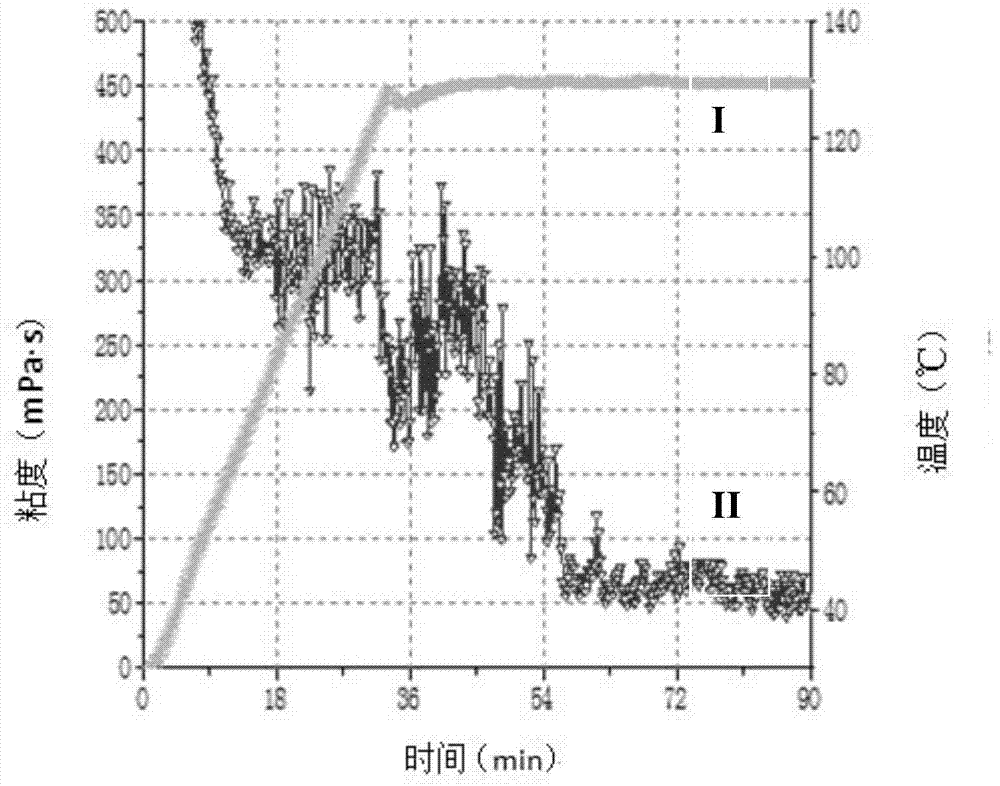

[0042] The mass ratio of each reaction raw material: water: ethylene glycol: zirconium tetrachloride: sodium hydroxide: triethanolamine: sodium gluconate: N, N ~ methylene bisacrylamide: butyl triester phosphate: potassium chloride is 40 :15:6:18:3:5:5:4:4.

[0043] (1) First add water to the reactor, and adjust the temperature of the reactor to 60°C, then add the solvent ethylene glycol while stirring, and stir for 1 hour;

[0044] (2) The temperature of the reaction kettle remains constant, and zirconium tetrachloride is added in the kettle, stirred to make it fully dissolved in the solvent, and NaOH is added to adjust the pH value to be 7.5, and the hydrolysis reaction is 0.5h;

[0045] (3) After all the raw materials in the reactor are dissolved, adjust the temperature of the reactor to 75°C, add the ligand triethanolamine, sodium gluconate and cross-linking agent N,N-methylenebisacrylamide into the solution, and stir until Dissolve completely, heat complexation reaction ...

Embodiment 3

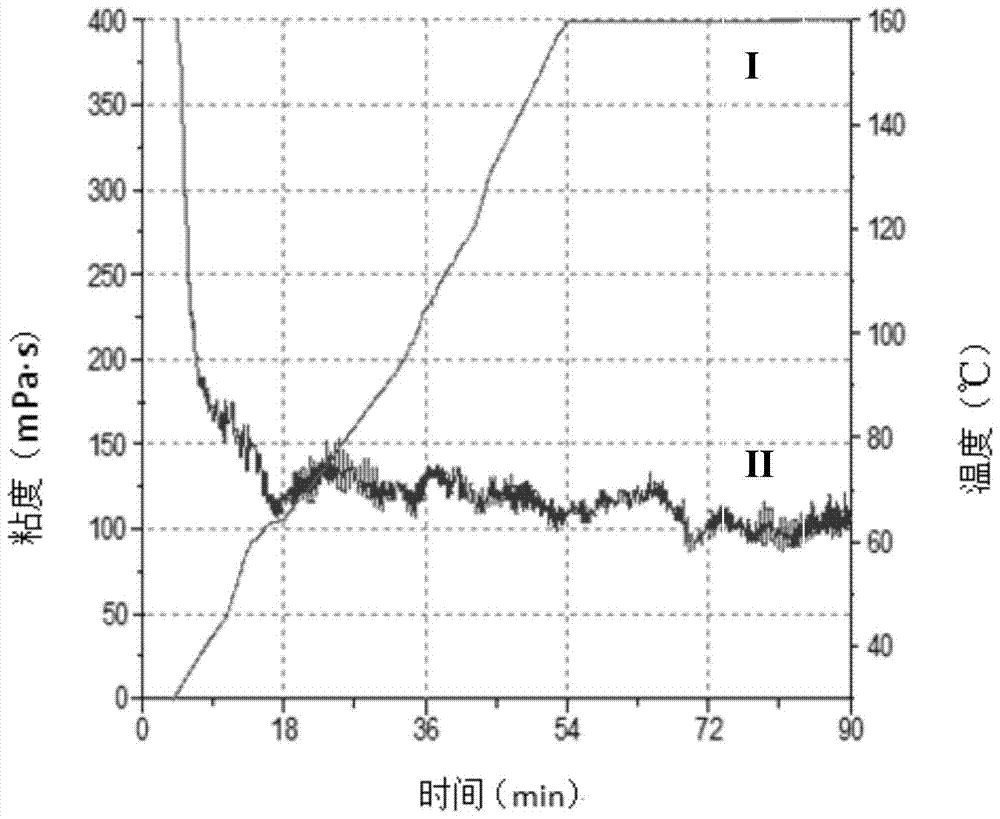

[0048] The mass percent of each reaction raw material is water: mannitol: zirconium tetrachloride: sodium hydroxide: bishydroxyethylglycine: sodium gluconate: N, N-methylenebisacrylamide: sodium thiosulfate=45:15 :7:20:3:5:3:2.

[0049] (1) First add water into the reactor, and adjust the temperature of the reactor to 50°C, then add the solvent mannitol while stirring, and stir for 1 hour;

[0050] (2) The temperature of the reaction kettle remains constant, and zirconium tetrachloride is added in the kettle, stirred to make it be fully dissolved in the solvent, and NaOH is added to adjust the pH value to be 8.5, and the hydrolysis reaction is 0.5h;

[0051] (3) After all the raw materials in the reactor are dissolved, adjust the temperature of the reactor to 70°C, and add ligand bishydroxyethylglycine, sodium gluconate and cross-linking agent N,N-methylenebisacrylamide to the solution , stirred until completely dissolved, and heated for complexation reaction for 2.5h;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com