Reutilization method and treatment device for flow-back fracturing fluid

A technology of fracturing flowback fluid and treatment equipment, which is applied in chemical instruments and methods, degassed water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as inoperability and complicated treatment process, and achieve economical installation Compared with the cost of disassembly, the process flow is short, and the effect of avoiding pipeline layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

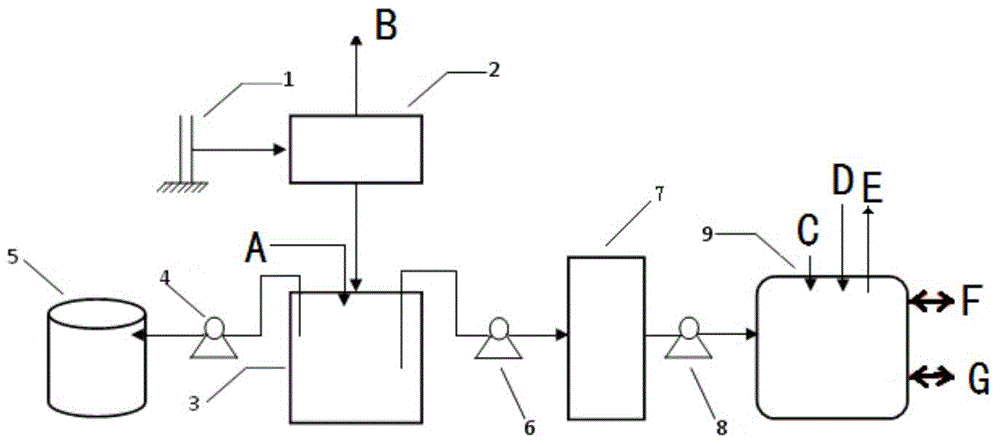

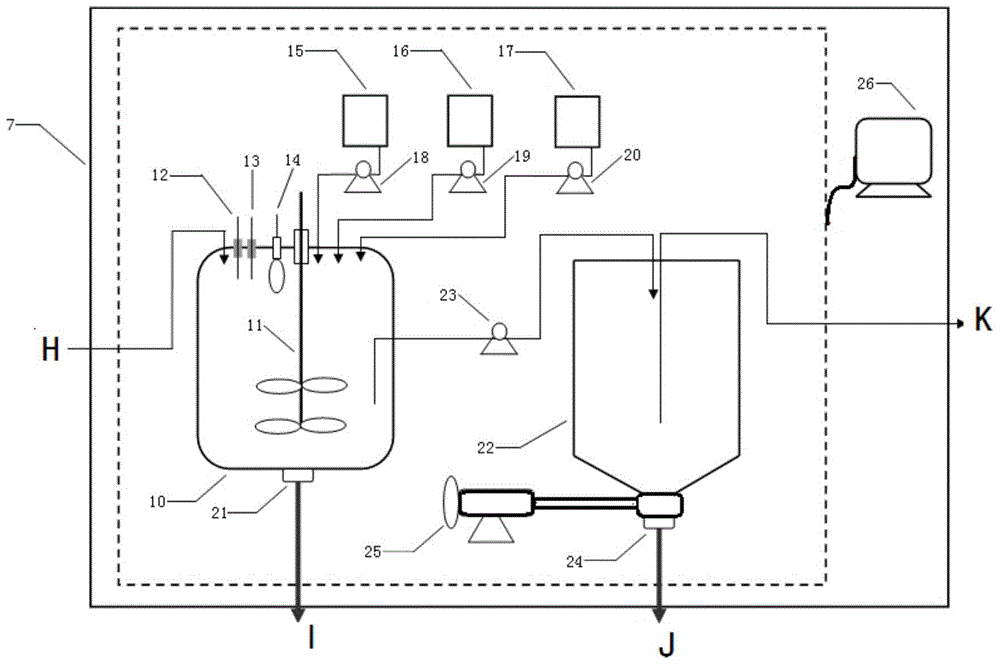

[0039] Embodiment one: if figure 1 , figure 2 As shown, a fracturing flowback fluid reuse method and treatment device.

[0040] Flowback well 1; gas-liquid separation device 2; settling tank 3; lift pump A4; oil storage tank 5; lift pump B6; fracturing flowback fluid treatment device 7; lift pump C8; fracturing fluid distribution tank 9; Flocculation tank 10; agitator 11; online pH meter 12; online TSS (total suspended solids) meter 13; ultraviolet sterilizer 14; chemical tank A15; chemical tank B16; chemical tank C17; metering pump A18; metering pump B19; Pump C20; slag outlet A21; centrifugal device 22; lift pump D23; slag outlet B24; motor 25; control system 26.

[0041] Terminal A is for adding demulsifier, terminal B is for gas combustion device combustion, terminal C is for adding bactericide, terminal D is for adding lost additives, terminal E is for repeated use of fracturing construction, terminal F is for residual concentration analysis of additives, terminal G F...

Embodiment 2

[0068] (1) The fracturing flowback fluid is discharged from the flowback well 1, and is separated from the gas and liquid by the gas-liquid separation device 2, the gas is burned in the gas combustion device, and the liquid enters the settling tank 3;

[0069] (2) There is oil and emulsion in the fracturing flowback fluid, add a measured amount of demulsifier to the liquid inlet of the settlement tank 3 to separate the oil and water after the emulsion is demulsified;

[0070] (3) Turn on the lifting pump A4, pump the separated oil into the oil storage tank 5, and pump the separated oil into the oil storage tank 5 1 to 3 times a day;

[0071] (4) The fracturing flowback fluid is naturally settled in the settlement tank 3 for one day, and the sand, cuttings and large particles of mechanical impurities in the flowback fluid are settled at the bottom of the tank;

[0072] (5) Turn on the lift pump B6 to pump the upper layer liquid in the settling tank 3 into the fracturing flowbac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com