Gel breaking and emulsion breaking oil-in-water emulsification fracturing fluid

A technology of oil-in-water and fracturing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems affecting the smooth flowback of fracturing fluid, and achieve good comprehensive performance of liquid, good anti-swelling effect, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

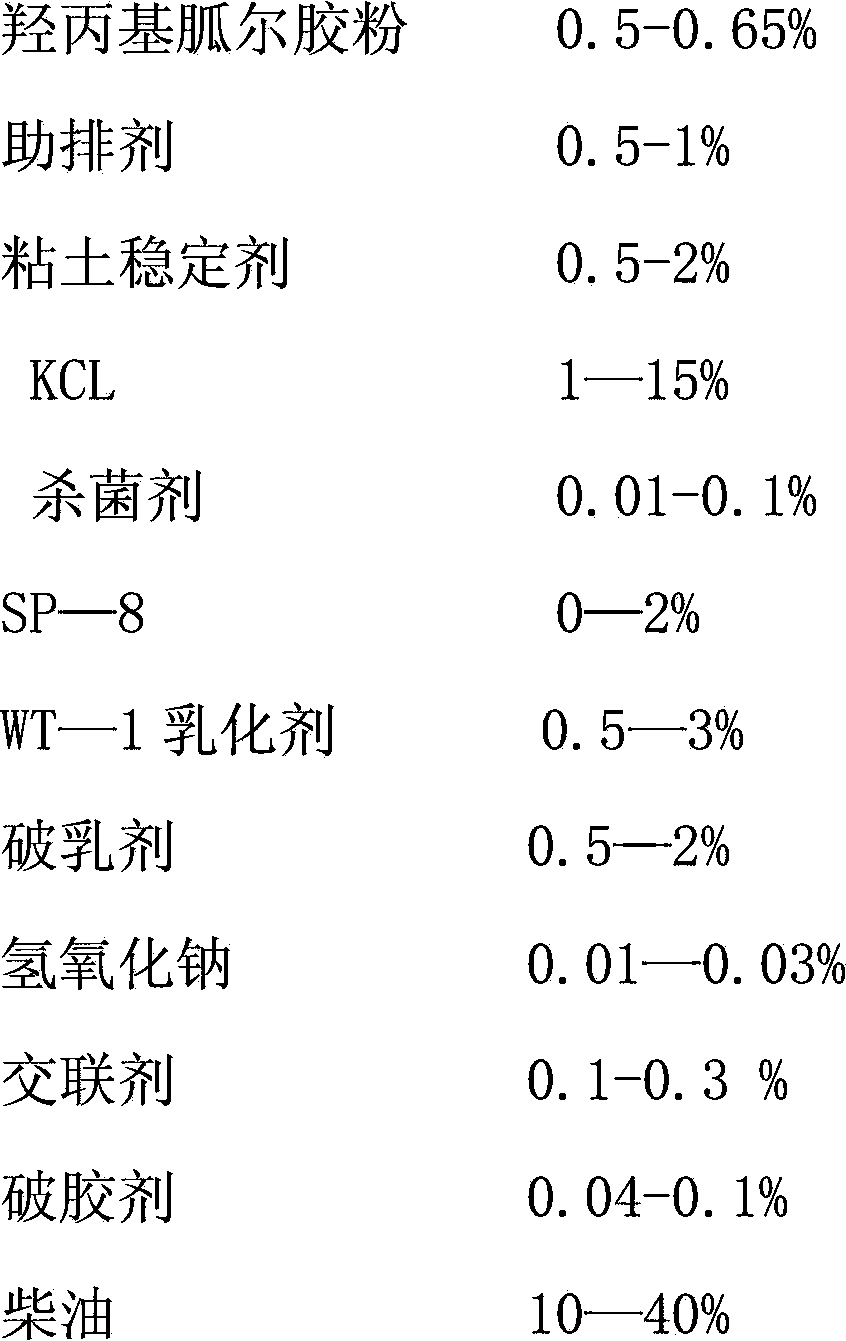

[0021] ① Formula of emulsified stock solution at 60°C: 0.5% HPGUR powder, 10% KCL, 0.5% XJHX-08, 1% ZJ-07 drainage aid, 0.3% KNF fungicide, 0.5% SP-80, 1% PR-1 and 0.02% sodium hydroxide.

[0022] ②Preparation method: Take 1000ml of water and place it in a 1000ml Wuyin mixer, add 100g of KCL, stir to dissolve, add 5.0g of hydroxypropyl guanidine gum powder, stir for 2 minutes to dissolve and increase viscosity, then add 2ml of XJHX-08, 10ml of ZJ -07 drainage aid, 3ml KNF bactericide, 5ml SP-80 emulsifier, 10ml PR-1 demulsifier, 0.2g sodium hydroxide, stir evenly, place in a 1000ml beaker and let it stand for 4 hours to make a base liquid for later use.

[0023] ③Crosslinking liquid formula: 1.5% YGB organic boron crosslinking agent + 0.6% sodium persulfate; take 100ml of water and put it in a 200ml beaker, add 1.5ml of YGB organic boron crosslinking agent, add 0.6g of sodium persulfate, stir Evenly, make a cross-linking solution for later use.

[0024] ④Cross-linking ratio:...

Embodiment 2

[0027] ① 70°C emulsified stock solution formula: 0.55% HPGUR powder + 10% KCL + 0.5% XJHX-08 + 1% ZJ-07 drainage aid + 0.3% KNF fungicide + 0.5% OP-10 + 1% WT-1 + 0.5% KXDT-1+0.024% sodium hydroxide

[0028] ②Preparation method: Take 1000ml of water and put it in a 1000ml Wuyin mixer, add 100g of KCL, stir to dissolve, add 5.5g of hydroxypropyl guanidine gum powder, stir for 2 minutes to dissolve and increase viscosity, then add 2ml of XJHX-08, 10ml of ZJ -07 drainage aid, 3ml KNF bactericide, 5ml OP-10, 10WT-1 emulsifier, 5ml KXDT-1 demulsifier, 0.24g sodium hydroxide, stir evenly, place in a 1000ml beaker and let it stand for 4 hours to make the base liquid for use.

[0029] ③Crosslinking liquid formula: 1.5% YGB organic boron crosslinking agent + 1% HT stabilizer + 0.25% sodium persulfate; take 100ml of water and put it in a 200ml beaker, add 1.5g of YGB organic boron crosslinking agent, add HT Stabilizer 1g, add sodium persulfate 0.25g, stir evenly, make cross-linking li...

Embodiment 3

[0033] ① 85°C emulsified stock solution formula: 0.65% HPGUR powder + 10% KCL + 0.5% XJHX-08 + 1% ZJ-07 drainage aid + 0.3% KNF fungicide + 1% OP-10 + 3% WT-1 + 1% KXDT-1+0.026% sodium hydroxide

[0034] ②Preparation method: Take 1000ml of water and place it in a 1000ml Wuyin mixer, add 100g of KCL, stir to dissolve, add 6.5g of hydroxypropyl guanidine gum powder, stir for 2 minutes to dissolve and increase viscosity, then add 2ml of XJHX-08, 10ml of ZJ -07 drainage aid, 3ml KNF bactericide, 10ml OP-10, 30WT-1 emulsifier, 10ml KXDT-1 demulsifier, 0.26g sodium hydroxide, stir evenly, place in a 1000ml beaker and let it stand for 4 hours to make the base liquid for use.

[0035] ③Crosslinking liquid formula: 2% YGB organic boron crosslinking agent + 2% HT stabilizer + 0.2% sodium persulfate; take 100ml of water and put it in a 200ml volume beaker, add 2g of YGB organic boron crosslinking agent, add HT to stabilize Add 2g of sodium persulfate, add 0.2g of sodium persulfate, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com