A kind of fracturing fluid thickener and its preparation and application

A fracturing fluid thickener and fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as low viscosity, restricted fracturing scale, poor temperature resistance, etc., to achieve viscosity increase Good effect, improved yield, fast dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

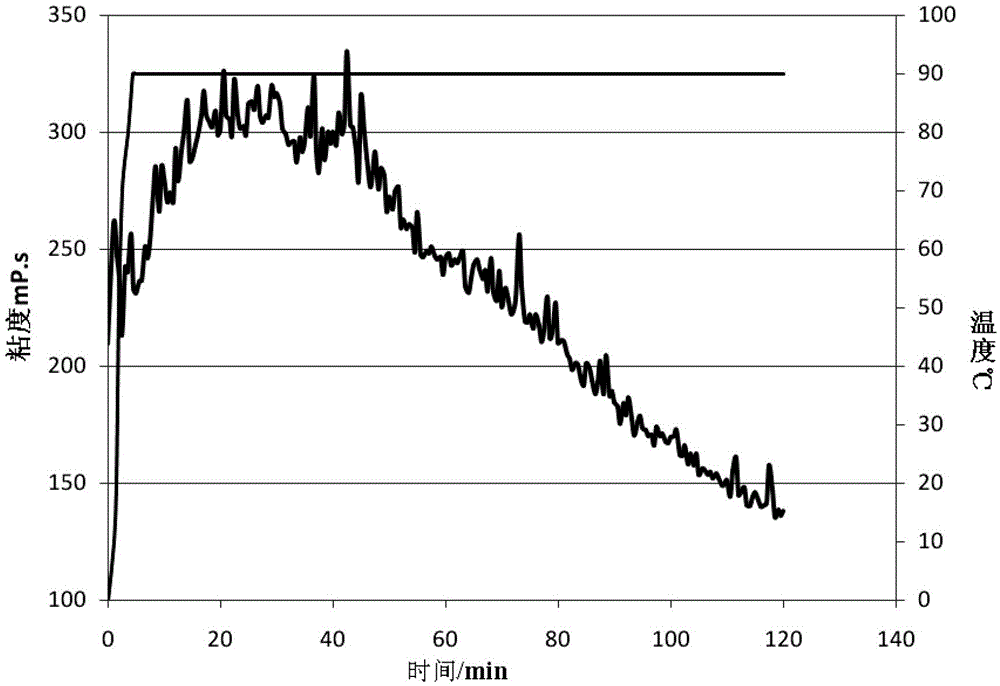

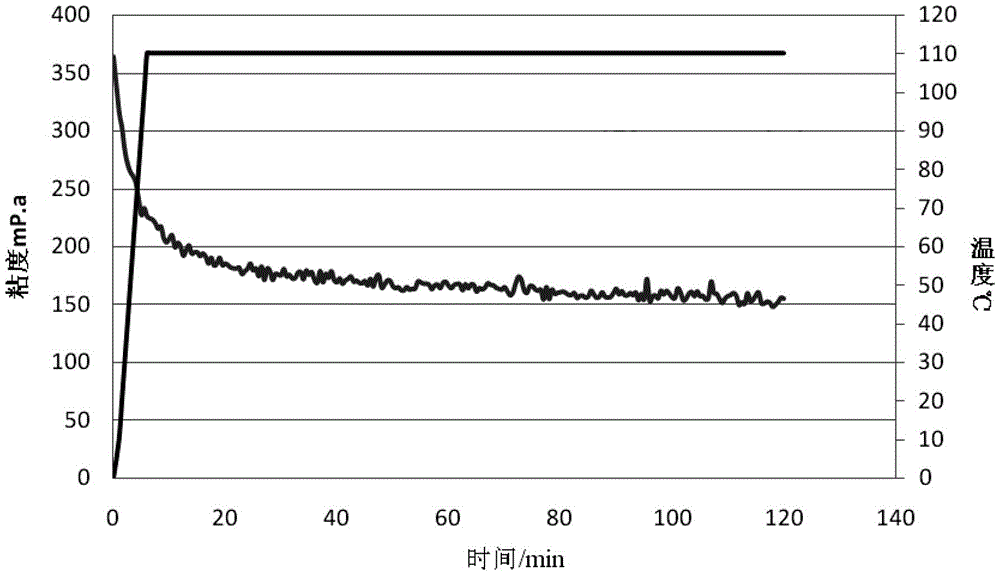

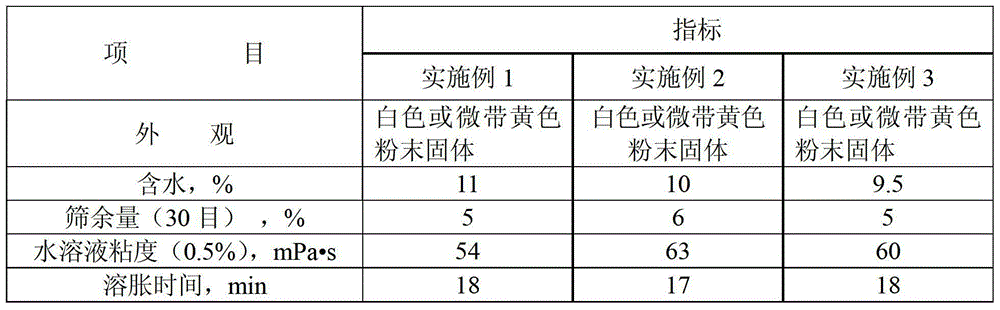

Examples

Embodiment 1

[0044] Preparation:

[0045] (1) Add 12g of acrylic acid monomer and 132g of water into a 500ml three-necked flask, start stirring and slowly add 6g of sodium carbonate, the feeding speed is based on the fact that the bubbles generated by the reaction do not overflow the three-necked flask, and stir for 20 minutes until fully dissolved;

[0046] (2) Slowly add 6g of 2-acrylamido-2-methylpropanesulfonic acid and stir for 20 minutes until fully dissolved;

[0047] (3) Add 30g of acrylamide monomer and 2g of dimethyl diallyl ammonium chloride (60% aqueous solution), stir for 20 minutes until fully dissolved; stir evenly, maintain the system temperature at 40 degrees, and pass nitrogen gas for 20 minutes;

[0048](4) Add 12ml of 1% potassium persulfate solution, continue to pass nitrogen for 30 minutes, stop stirring, and react for 4 hours to obtain a gel;

[0049] (5) The reaction product in step (4) is pulverized, dried and granulated to obtain the thickener.

Embodiment 2

[0051] (1) Add 16g of acrylic acid monomer and 118g of water into a 500ml three-necked flask, start stirring and slowly add 9g of sodium carbonate, the feeding speed is based on the fact that the bubbles generated by the reaction do not overflow the three-necked flask, and stir for 20 minutes until fully dissolved;

[0052] (2) Slowly add 10g of 2-acrylamido-2-methylpropanesulfonic acid, stir for 20min until fully dissolved;

[0053] (3) Add 35g of acrylamide monomer and 4g of dimethyl diallyl ammonium chloride (60% aqueous solution), stir for 20 minutes until fully dissolved; stir evenly, maintain the system temperature at 40 degrees, and pass nitrogen gas for 20 minutes;

[0054] (4) Add 8ml of 1% potassium persulfate solution, continue to pass nitrogen for 30 minutes, stop stirring, and react for 4 hours to obtain a gel;

[0055] (5) The reaction product in step (4) is pulverized, dried and granulated to obtain the thickener.

Embodiment 3

[0057] (1) Add 20g of acrylic acid monomer and 96g of water into a 500ml three-necked flask, start stirring and slowly add 12g of sodium carbonate, the feeding speed is based on the fact that the bubbles generated by the reaction do not overflow the three-necked flask, and stir for 20 minutes until fully dissolved;

[0058] (2) Slowly add 16g of 2-acrylamido-2-methylpropanesulfonic acid and stir for 20 minutes until fully dissolved;

[0059] (3) Add 40g of acrylamide monomer and 8g of dimethyl diallyl ammonium chloride (60% aqueous solution), stir for 20 minutes until fully dissolved; stir evenly, maintain the system temperature at 40 degrees, and pass nitrogen gas for 20 minutes;

[0060] (4) Add 8ml of 1% potassium persulfate solution, continue to pass nitrogen for 30 minutes, stop stirring, and react for 4 hours to obtain a gel;

[0061] (5) The reaction product in step (4) is pulverized, dried and granulated to obtain the thickener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com