A kind of fracturing fluid crosslinking agent and its preparation and application

A technology of cross-linking agent and fracturing fluid, which is applied to chemical instruments and methods, drilling compositions and other directions, can solve the problems of cumbersome procedures, unfavorable construction, combined with the description of reaction methods, etc., and achieves simple preparation process and improved economic benefits. , the effect of low price of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

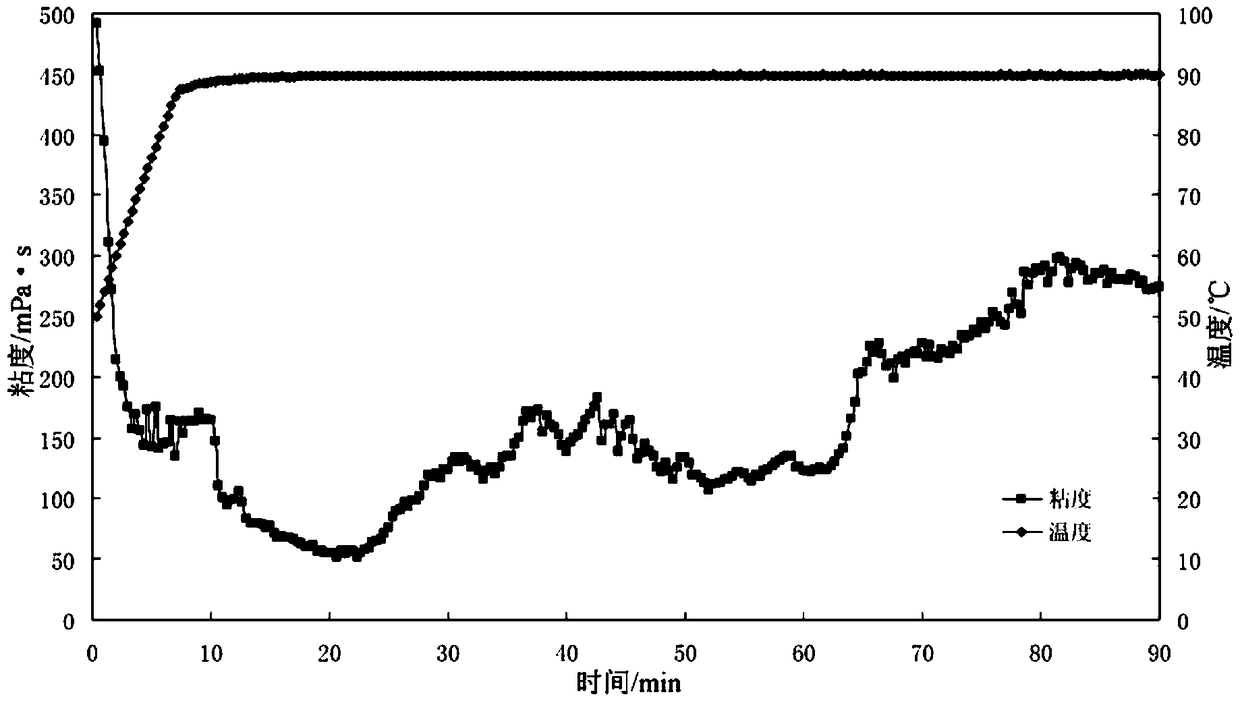

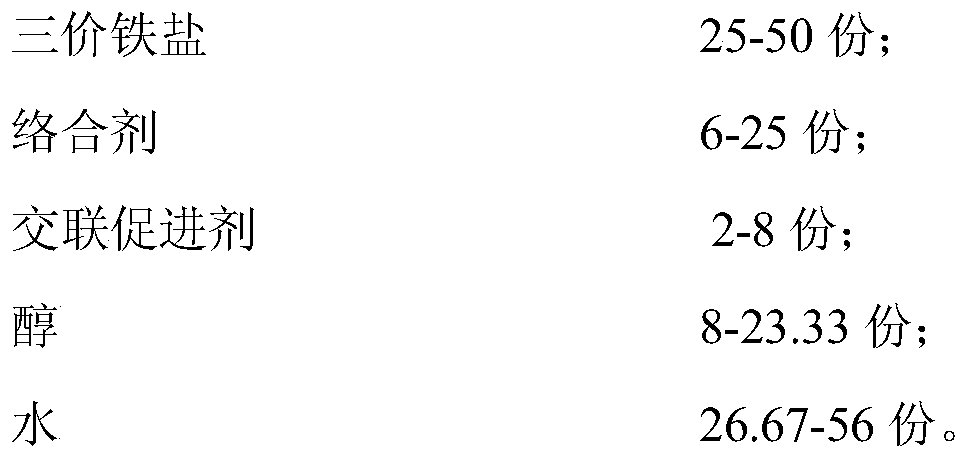

Embodiment 1

[0045] Mix 9 parts of ethylene glycol with 27 parts of water to form a composite solvent, place it in a 250ml four-neck flask equipped with a mechanical stirrer, a condenser, and a thermometer, then add 30 parts of iron sulfate and 7 parts of triethanolamine in sequence at 60°C The reaction was carried out for 4 hours. After the reaction was completed, it was left to stand. When the temperature dropped to about 30°C, 3 parts of fatty alcohol polyoxyethylene ether AEO-09 were added and stirred evenly to obtain a crosslinking agent.

Embodiment 2

[0047] Mix 16 parts of glycerol with 52 parts of water to form a composite solvent, place it in a 250ml four-neck flask equipped with a mechanical stirrer, a condenser, and a thermometer, then add 50 parts of iron nitrate and 7 parts of triethanolamine in sequence at 60°C The reaction was carried out for 4 hours. After the reaction was completed, it was left to stand. When the temperature dropped to about 30° C., 8 parts of polyoxyethylene fatty acid ester (produced by Haian Petrochemical Factory in Jiangsu Province) were added and stirred evenly to obtain a crosslinking agent.

Embodiment 3

[0049] Mix 18 parts of glycerol with 35 parts of water to form a composite solvent, place it in a 250ml four-necked flask equipped with a mechanical stirrer, a condenser, and a thermometer, then add 40 parts of iron sulfate and 21 parts of ethanolamine in sequence at 60°C React for 4 hours, let stand after the reaction, and when the temperature drops to about 30°C, add 5 parts of alkylphenol polyoxyethylene ether (OP-10, produced by Shenzhen Qiyanglong Technology Co., Ltd.), and stir evenly to obtain a crosslinking agent .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com