Method for preparing fracturing fluid by utilizing polymer type fracturing flow-back fluid

A technology of fracturing flowback fluid and fracturing fluid, which is applied in the direction of drilling composition, chemical instruments and methods, and special compound water treatment, which can solve pollution and other problems, achieve pollution, improve effect, and increase biological activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

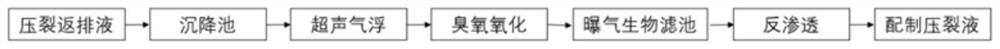

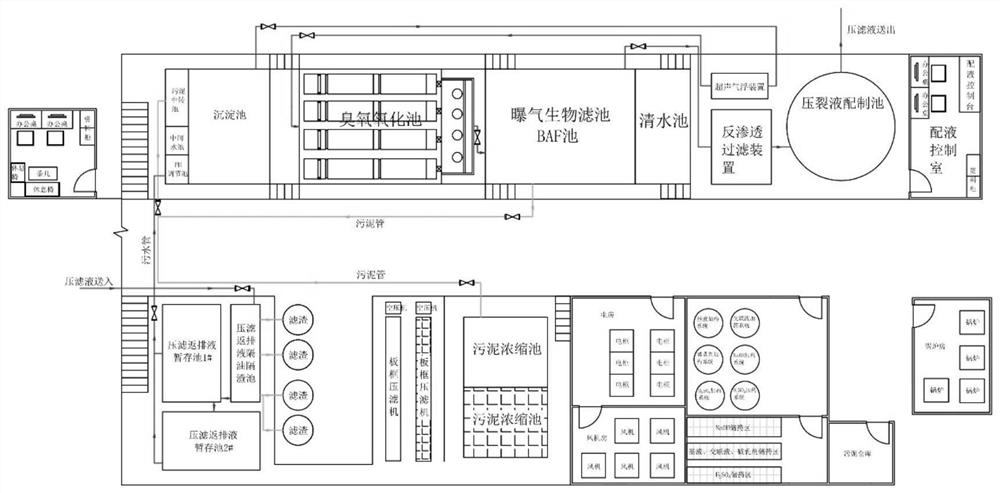

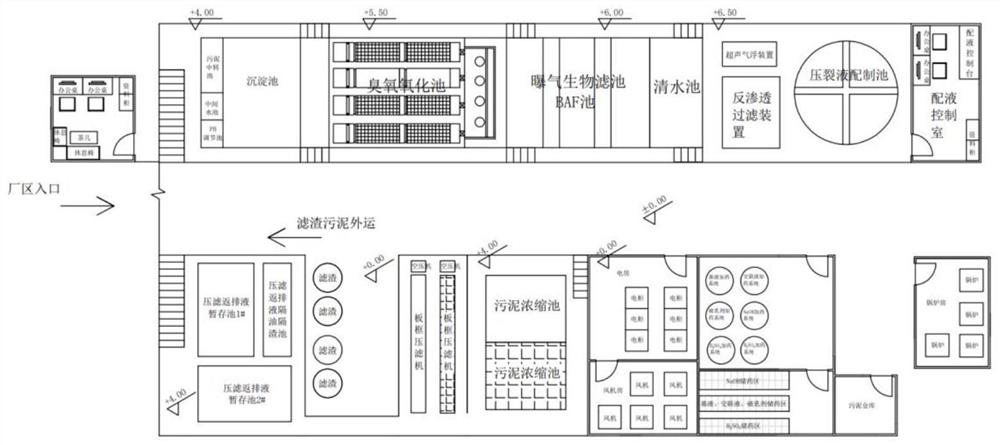

[0021] Specific embodiment one: In this embodiment, a method for preparing fracturing fluid by using polymer-type fracturing flowback fluid is carried out according to the following steps:

[0022] 1. Inject the fracturing flowback fluid into the sedimentation tank, and after 12-18 hours of natural settlement, pump it into the ultrasonic air flotation device, ultrasonically float it for 30-60 minutes under the ultrasonic power of 200-400W, and then pump it into the ozone catalytic oxidation tank , treated with ozone for 2-4 hours at an ozone mass concentration of 40-80mg / L, and then pumped into the biological aerated filter. Osmotic filtration and high-pressure reverse osmosis filtration with an operating pressure of 10-13 MPa to obtain the fracturing flowback fluid after reverse osmosis treatment, adding nano-zinc oxide to the biological aerated filter tank, the addition amount of nano-zinc oxide is 0.02- 0.04g / L; when carrying out ozone catalytic oxidation in the ozone catal...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: In step 1, the fracturing flowback fluid is injected into the settling tank, and it settles naturally for 12 hours.

[0035] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the pump is pumped into the ultrasonic air flotation device, and the ultrasonic air flotation is carried out for 30 minutes under the ultrasonic power of 200W; Hydrogen peroxide and ozone are introduced, and the dosage of hydrogen peroxide is 0.5L / t.

[0037] Other steps are the same as those in Embodiment 1 or 2.

[0038] Hydrogen peroxide is a strong oxidizing agent that can degrade some organic pollutants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com