Model sticky dyed parent-child clothing dyed with indigo blue and made of beautiful skin velvet antibacterial shell fabric

A technology of antibacterial fabric and skin-beautifying velvet, applied in the field of clothing design, can solve the problems of synthetic dye pollution, anti-dye paste easy to fall, anti-dye paste easy to fall off, etc., achieve loose clothing, strengthen antibacterial and antibacterial performance, solid good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] garment dyeing process

[0125] 1. Plate making

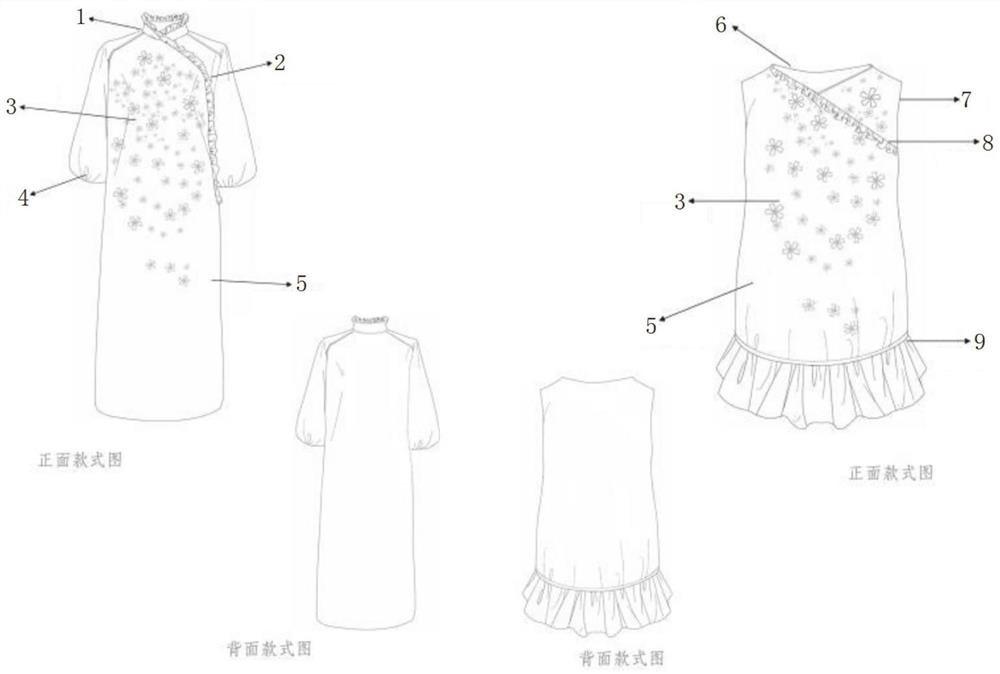

[0126] According to the style of women's clothing, the board is made on the skin-friendly fleece fabric and sewed.

[0127] 2. Fabric desizing

[0128] (1) Put water into the pot, add 20g of edible alkali and 20g of salt respectively, and stir until it melts.

[0129] (2) Add the fabric and boil, turn to 80°C and cook for 90 minutes. After cooking, wring out the fabric, change the water in the pot and cook for 60 minutes.

[0130] (3) Wash the boiled fabric repeatedly until the clear water is no longer yellow.

[0131] 3. Production of type paste dyeing resist paste

[0132] (1) Make anti-dyeing paste

[0133] ① Prepare soybean powder and lime powder in a ratio of 4:6, and the ratio of water to mixed powder is 1:1.

[0134] ②Through the soybean powder and lime powder through a fine sieve of 60 mesh and 80 mesh respectively.

[0135] ③Slowly add water to the mixed powder and stir until it hangs down slightly.

[0...

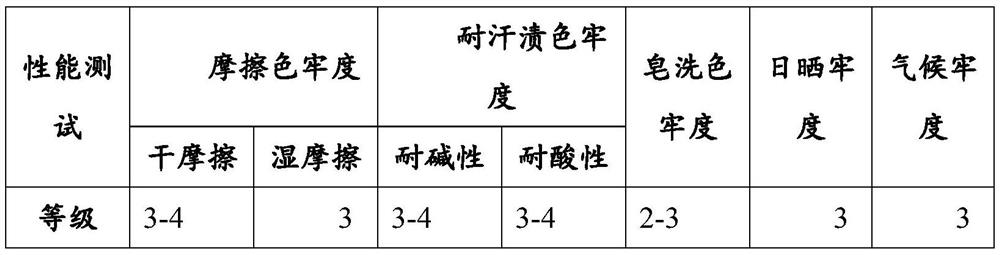

Embodiment 2

[0164] Garment dyeing process is substantially the same as Example 1, and the difference is that 5. (2) "color fixation" processing steps are as follows:

[0165] HTF-148 formaldehyde-free color-fixing agent: the water ratio is 1:120, pour 50ml of formaldehyde-free color-fixing agent into a container, then pour 6000ml of water and stir evenly, put the dyed fabric into the container, and let it stand for 45 minutes Take it out and clean it.

[0166] The performance test results are shown in Table 2:

[0167] Table 2

[0168]

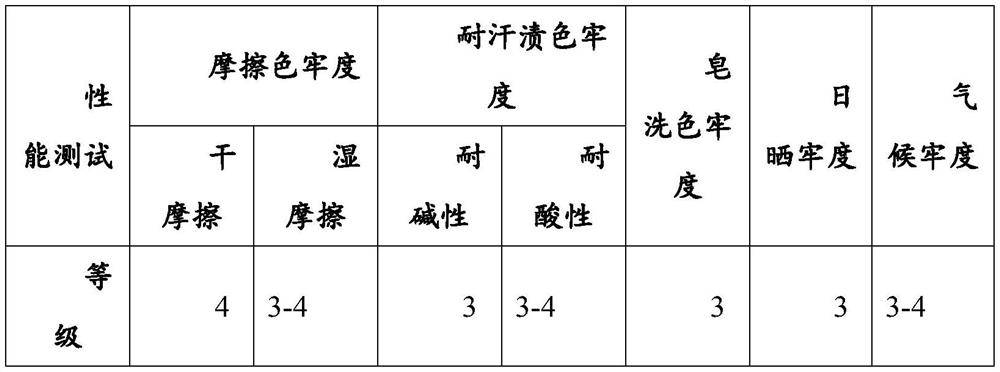

Embodiment 3

[0170] Garment dyeing process is substantially the same as Example 1, and the difference is that 5. (2) "color fixation" processing steps are as follows:

[0171] Vinegar: HTF-148 formaldehyde-free color fixing agent: water is 0.5:0.5:120, pour 50ml of edible white vinegar into a container, then pour 6000ml of water and stir evenly, put the dyed fabric into the container and let it stand for 20 minutes Then take it out and clean it. Pour 50ml of formaldehyde-free color-fixing agent into the container, then pour 6000ml of water and stir evenly, put the dyed fabric into the container, let it stand for 45 minutes, take it out and clean it.

[0172] The performance test results are shown in Table 3:

[0173] table 3

[0174]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com