Direct discharge treatment method for high-salinity fracturing flow-back fluid

A fracturing flowback fluid and treatment method technology, applied in mining wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as poor treatment effect and secondary pollution treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

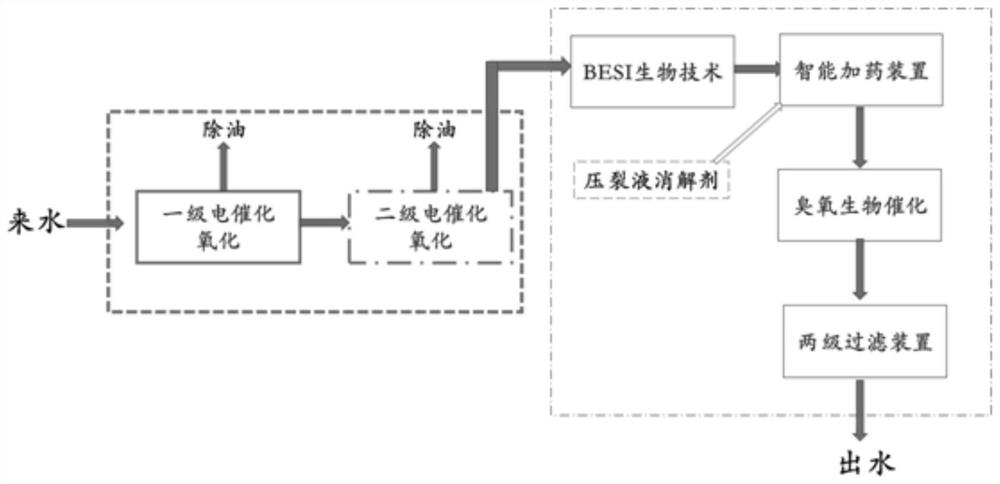

[0017] Specific implementation mode 1: In this implementation mode, a direct discharge treatment method of high-salinity fracturing flowback fluid is carried out according to the following steps:

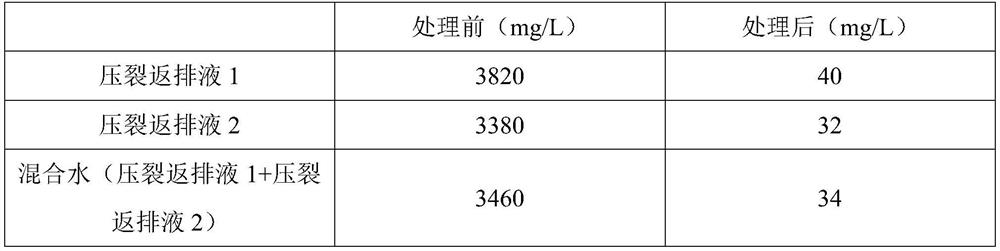

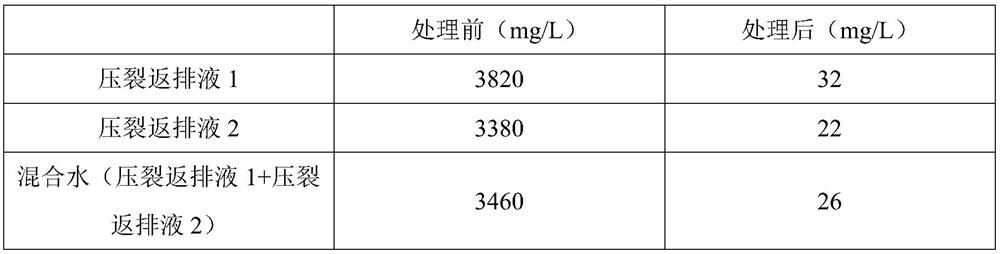

[0018] The fracturing flowback fluid is subjected to the first-level electrocatalytic oxidation treatment and the second-level electrocatalytic oxidation treatment in sequence to obtain the fracturing flowback fluid after the electrocatalytic oxidation treatment, and the fracturing flowback fluid after the electrocatalytic oxidation treatment is subjected to BESI biological treatment to obtain the fracturing flowback fluid after BESI biological treatment, and then add fracturing fluid digestion agent to the fracturing flowback fluid after BESI biological treatment, and react for 20-50 minutes to obtain the fracturing flowback fluid after chemical treatment The dosing amount of the fracturing fluid digestion agent is 10-40mg / L; then the fracturing flowback fluid after the chemical tre...

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that when the fracturing flowback fluid is subjected to the first-level electrocatalytic oxidation treatment and the second-level electrocatalytic oxidation treatment, the air flotation treatment is carried out at the same time, and the water that rises to the fracturing is removed. Oil droplets on the surface of the flowback fluid.

[0028] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the sulfur electron acceptor is sodium sulfate, sodium sulfite or sodium thiosulfate.

[0030] Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com