Abrasive jetting device and method for abrasive jetting flow and jetting perforation and multiple fracturing

A spraying device and abrasive technology, which is applied in the direction of spraying device, liquid spraying device, mining fluid, etc., can solve the problem that the fracturing fluid and proppant cannot enter the fractured layer, so as to improve the isolation effect and avoid sand card effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

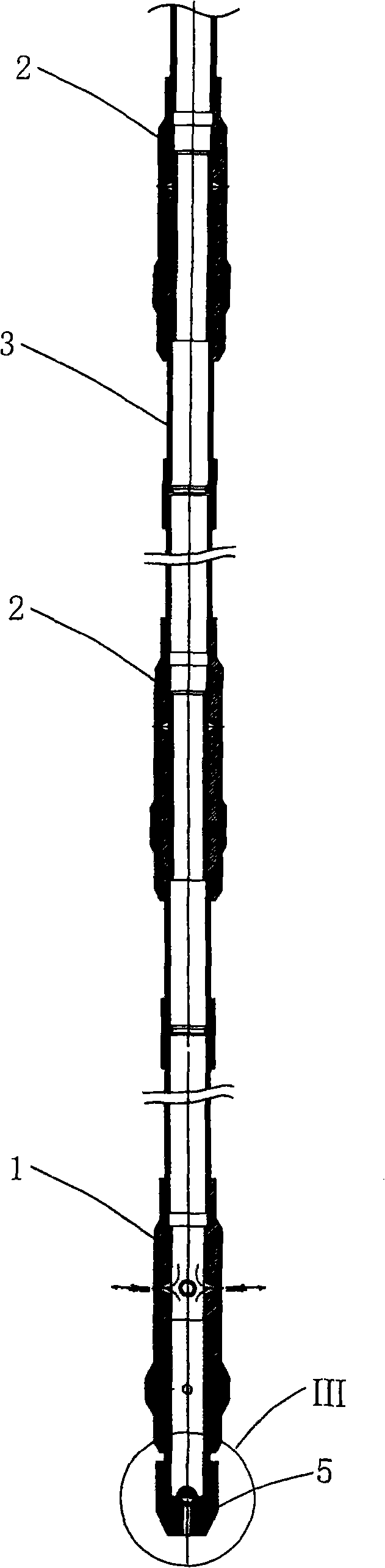

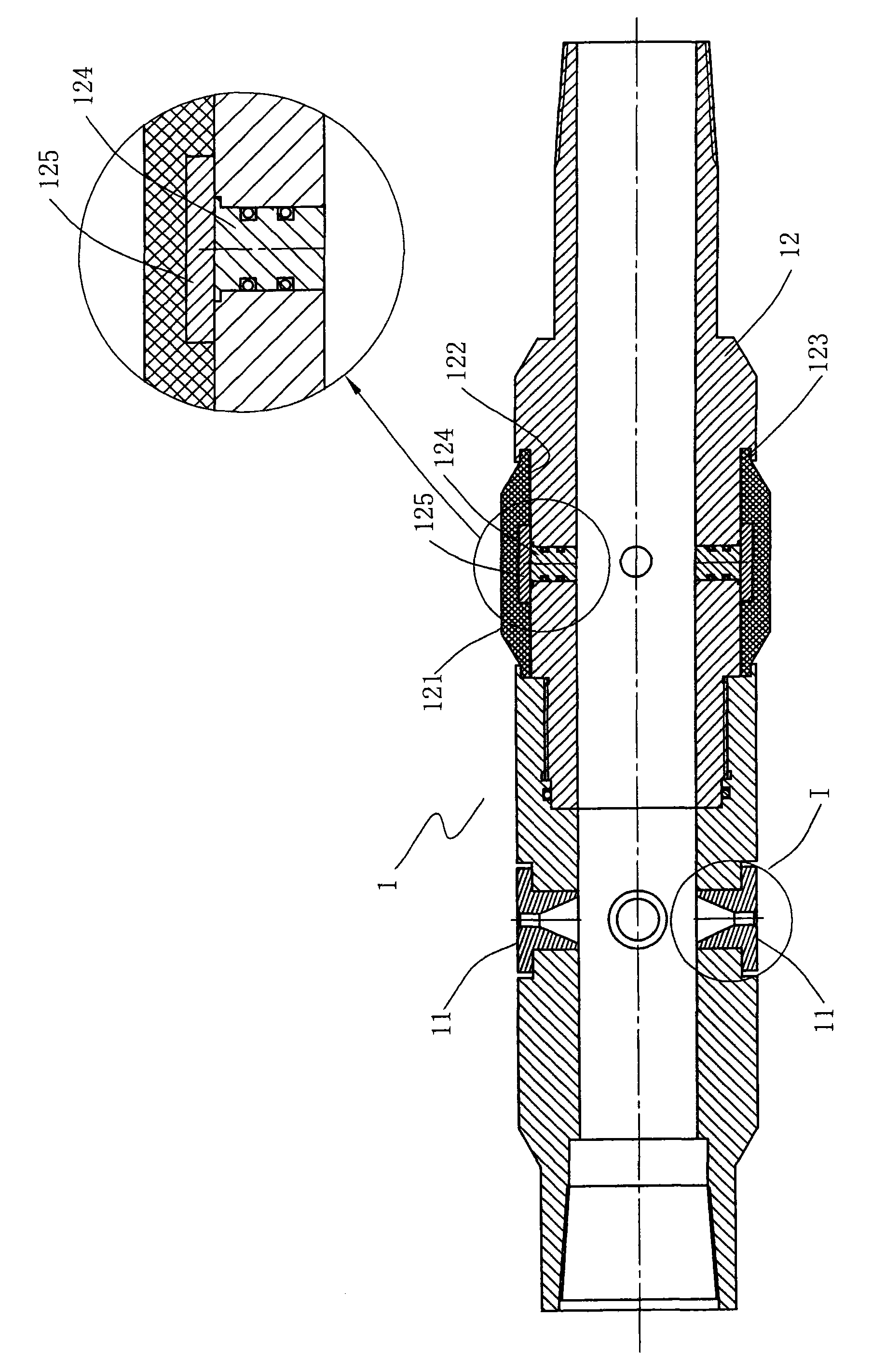

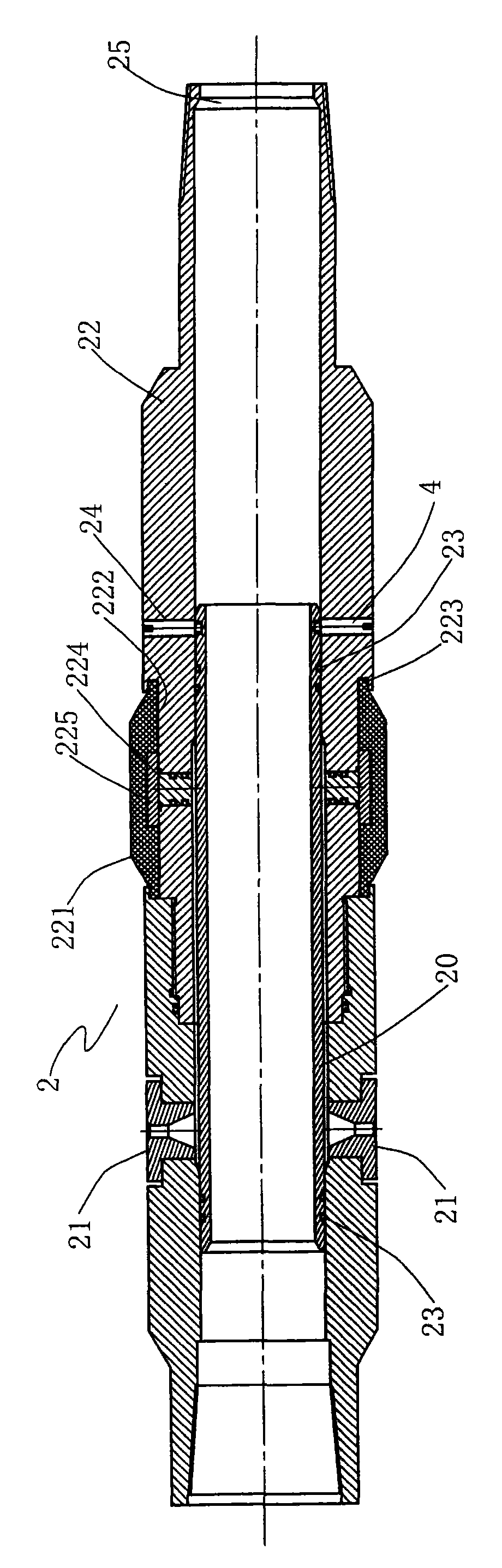

[0034] figure 1 is a schematic structural view of the abrasive jetting device of the present invention; figure 2It is a schematic diagram of the structure of the first-stage bottom spray gun of the abrasive jetting device of the present invention; image 3 It is a schematic diagram of the structure of the second-stage upper spray gun of the abrasive spraying device of the present invention, which is in the closed state of the spray gun; Figure 4 It is a schematic diagram of the structure of the second-stage upper spray gun of the abrasive jetting device of the present invention, which is in the open state of the spray gun. As shown in the figure, the abrasive injection device of the present invention has multi-stage spray gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com