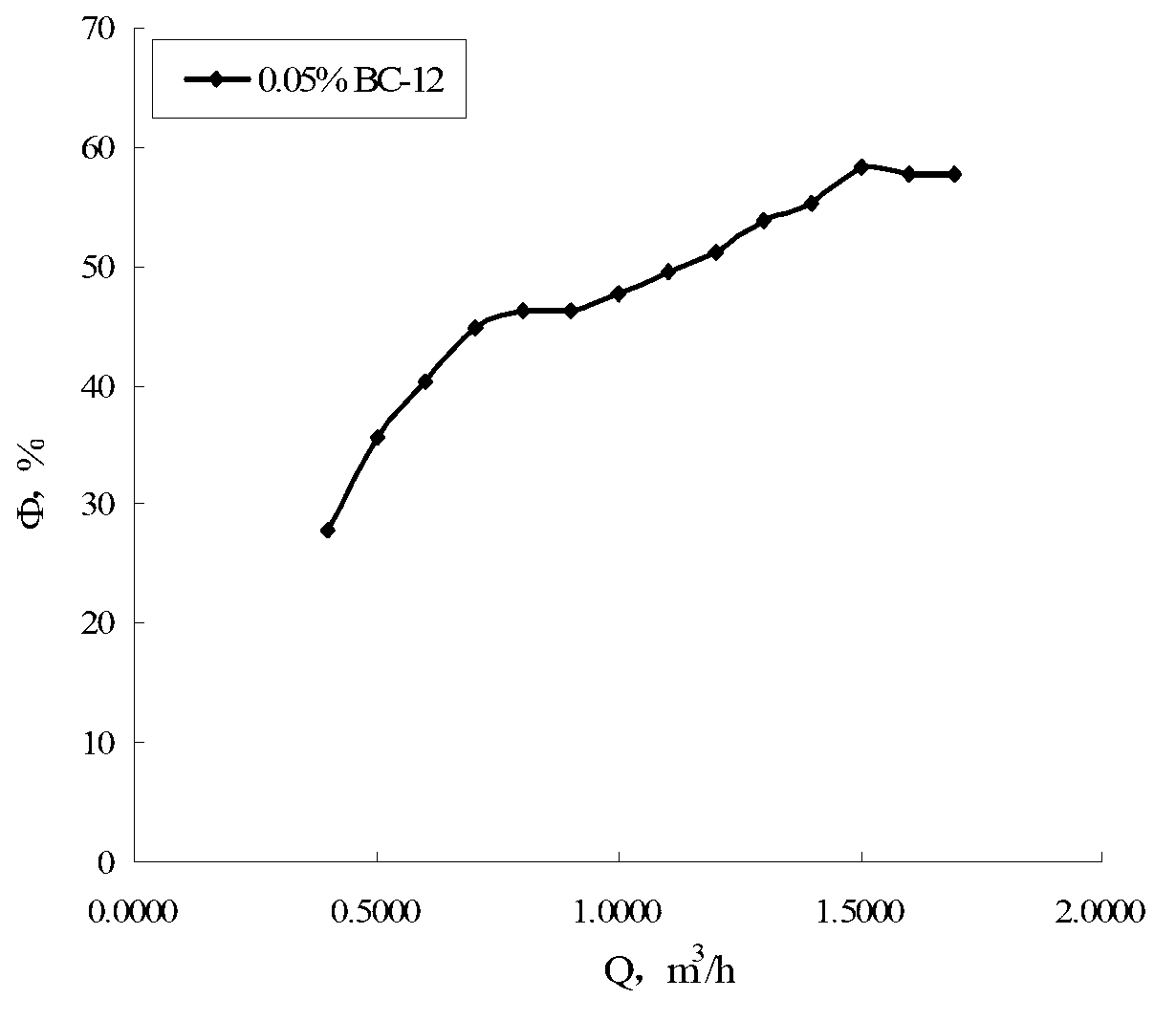

Slickwater fracturing fluid drag reducer and preparation method thereof

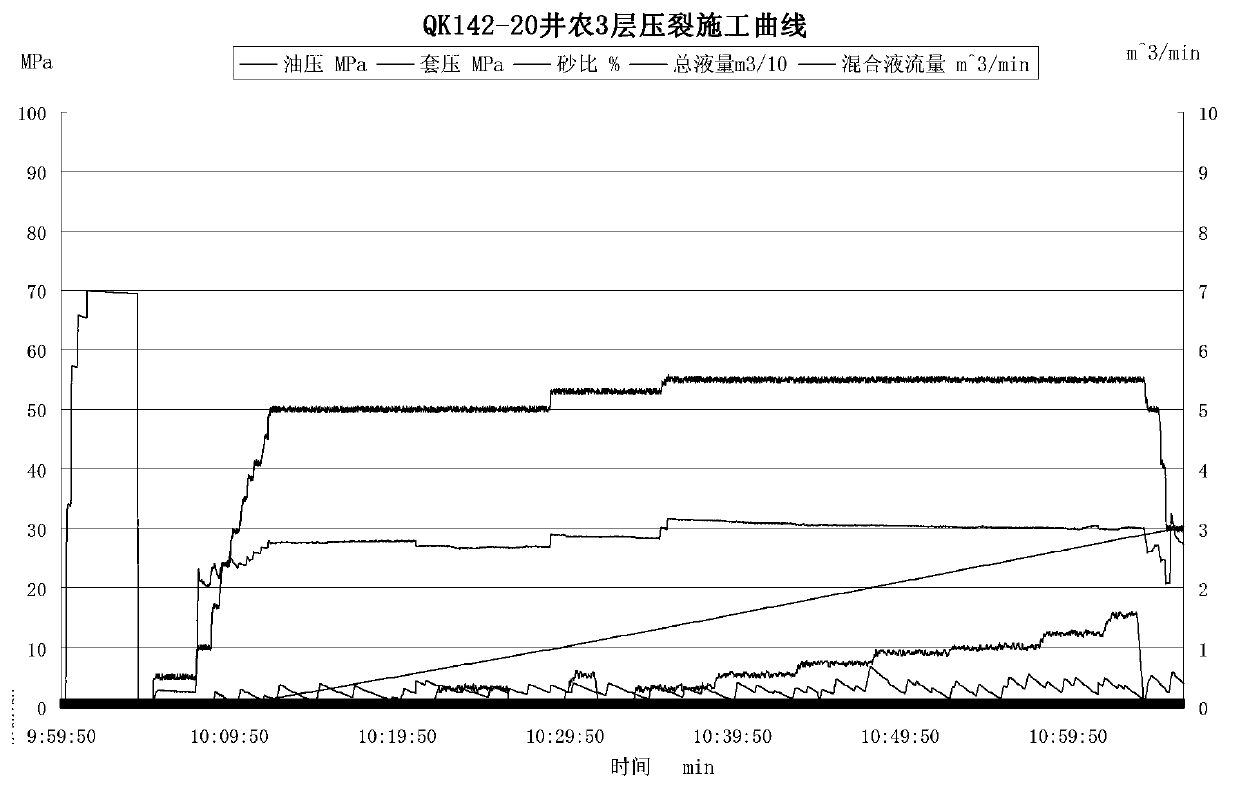

A technology of hydraulic fracturing and drag reducing agent, which is applied in low-porosity unconventional reservoir reconstruction and low-permeability fields. It can solve the problems of large oil and water and the complexity of microemulsion systems, and achieve fast dissolution, good fracturing effect, and stable good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

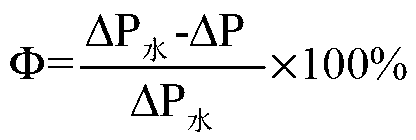

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments.

[0022] Dissolve monomer acrylamide and functional monomer MAA (methacrylic acid) in 3% NaCl aqueous solution at a mass ratio of 3:1 to form an aqueous solution with a monomer mass concentration of 33%, which is the aqueous phase;

[0023] Mix and dissolve the surfactant and cyclohexane at a mass ratio of 2:9, and add it to a four-necked flask equipped with a reflux condenser, a thermometer, and a stirrer, wherein the surfactants are Span-80 and Tween-60 at a ratio of 4:3 It is compounded with the mass ratio of HLB=8.7. Place the four-neck flask in a constant temperature bath pot at 45°C, blow nitrogen gas and stir for 15-20 minutes, slowly drop the water phase into the four-necked flask, the ratio of oil to water is 2:3, continue stirring with nitrogen gas for 30 minutes to make it fully emulsified ; Slowly add water-soluble initiator AIBI and oil-soluble initiator V-65 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com