Horizontal well liquid nitrogen ice crystal temperature plugging staged fracturing method for coalbed methane

A staged fracturing and horizontal well technology, which is applied in the field of oil and gas well fracturing, can solve the problems of high risk of sand burial of packers, difficulty in lifting the pipe string, and poor segmentation pertinence, so as to increase the permeability of coal and rock, The effect of increasing production is obvious and the effect of increasing the deflated area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The staged fracturing method for temporary plugging of liquid nitrogen ice crystals in horizontal coalbed methane wells in this embodiment includes the following steps:

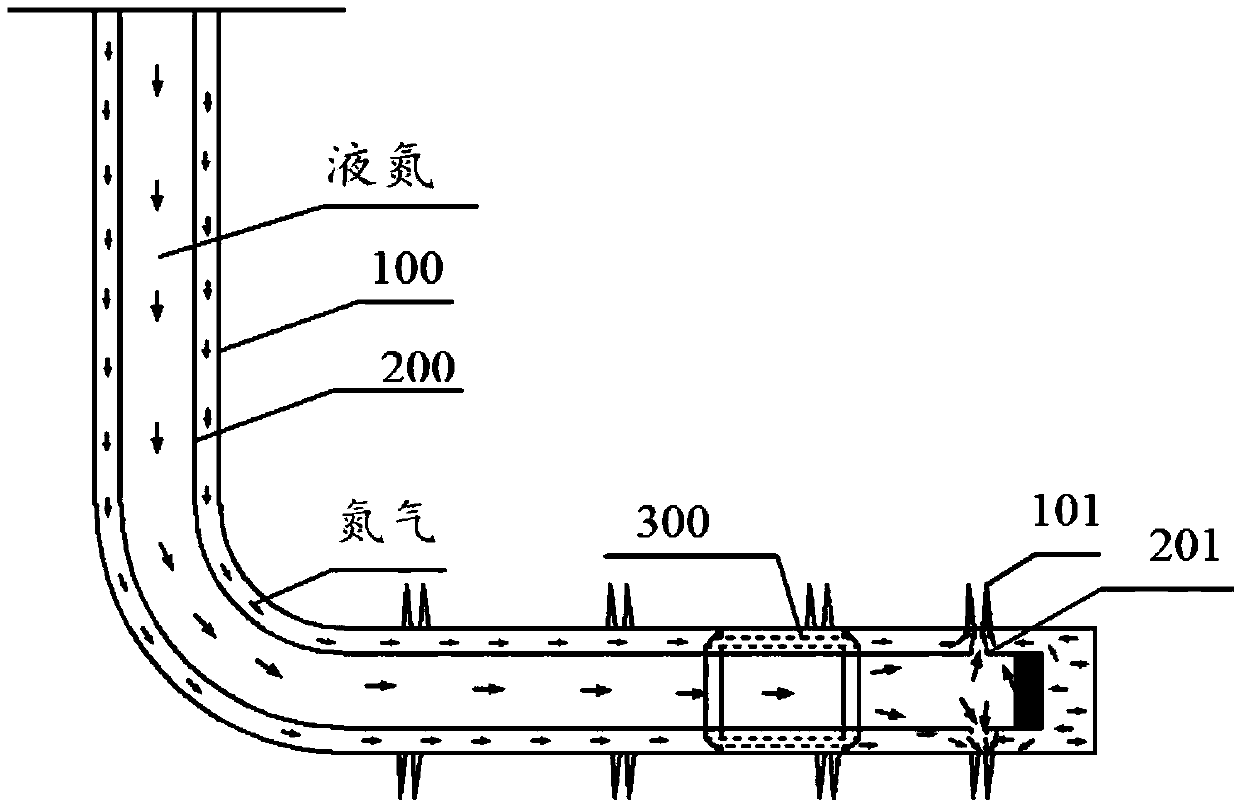

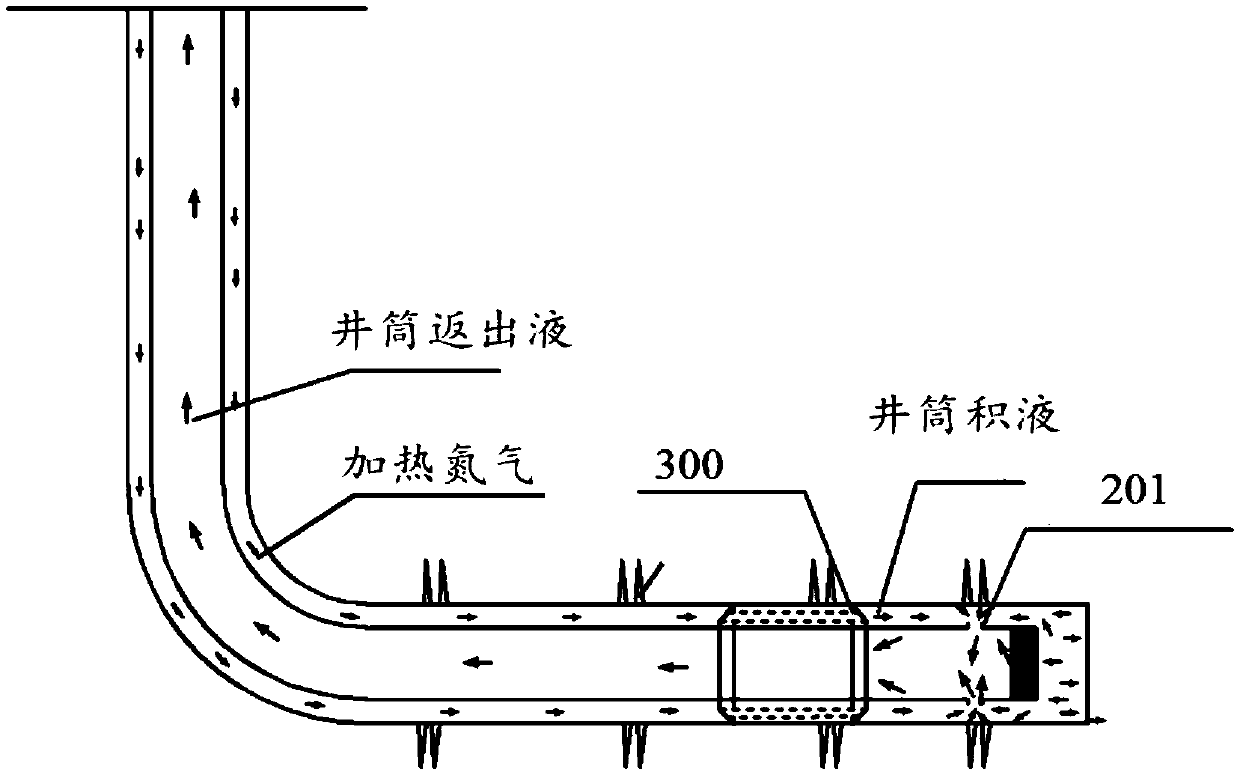

[0073] S11: Shot open the interval, run the heat-insulated tubing 200 into the jacket 100 in the horizontal well, set the interval to be fractured with a single-channel packer 300 , and inject it into the annular space between the jacket 100 and the heat-insulated tubing 200 Inject hot nitrogen to discharge wellbore fluid;

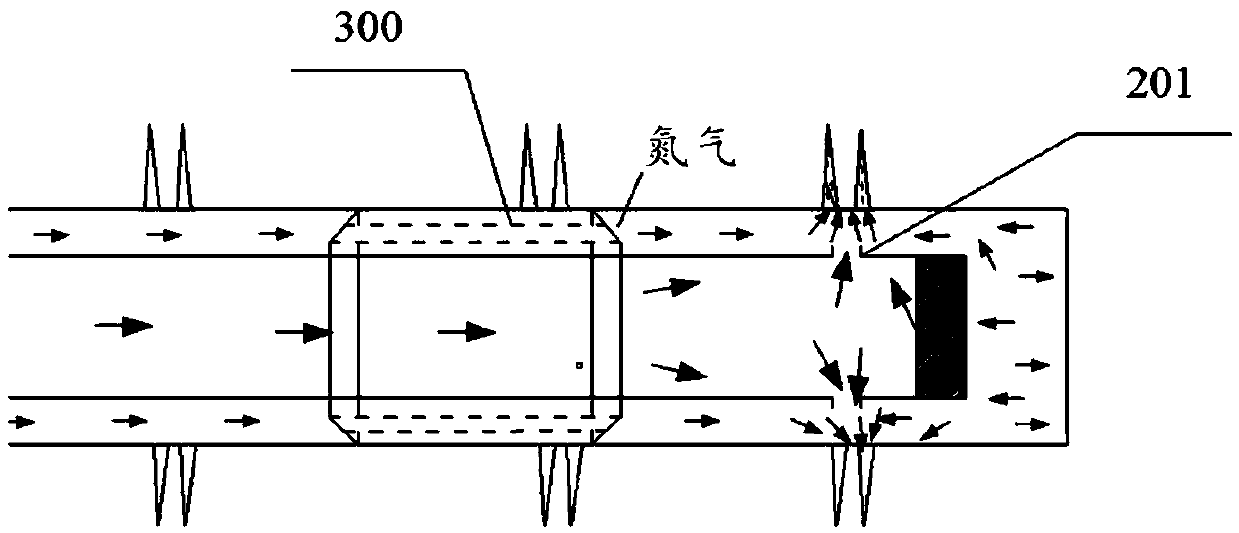

[0074] According to the on-site construction design, all intervals are shot open, the heat-insulated tubing 200 is lowered and the single-channel packer 300 is set (set on the outer wall of the heat-insulated tubing 200 and fixed relatively to the inner wall of the jacket 100 after setting), Make the liquid outlet 201 of the heat-insulated tubing 200 face the perforation hole 101 corresponding to the interval to be fractured on the jacket 100, inject hot nitrogen into the annular spa...

Embodiment 2

[0083] A staged fracturing method for temporary plugging of liquid nitrogen ice crystals in horizontal coalbed methane wells, comprising the following steps:

[0084] S21: Shot open the interval, run the heat-insulated tubing 200 into the jacket 100 in the horizontal well, set the interval to be fractured with a single-channel packer 300 , and run it into the annular space between the jacket 100 and the heat-insulated tubing 200 Inject nitrogen at a temperature of 30°C to discharge wellbore fluid;

[0085] Wherein, in this step, according to the interval to be fractured, two rows of perforation holes 101 are arranged symmetrically along the axial direction on the pipe wall in the horizontal section of the jacket 100 in advance, and in order to facilitate fracturing, the perforation holes 101 The cement sheath outside the corresponding overcoat 100 of the place also drills a small gap.

[0086] S22: Inject hot nitrogen into the heat-insulated oil pipe 200 and the annular space...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst pressure | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Burst pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com