Efficient horizontal position welding process method for pumping storage seat ring fixed guide vane

A technology for fixing guide vanes and process methods, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of unstable quality, high labor intensity, low production efficiency, etc., and achieve small heat-affected zone range and low labor intensity The effect of reducing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Technical scheme of the present invention is:

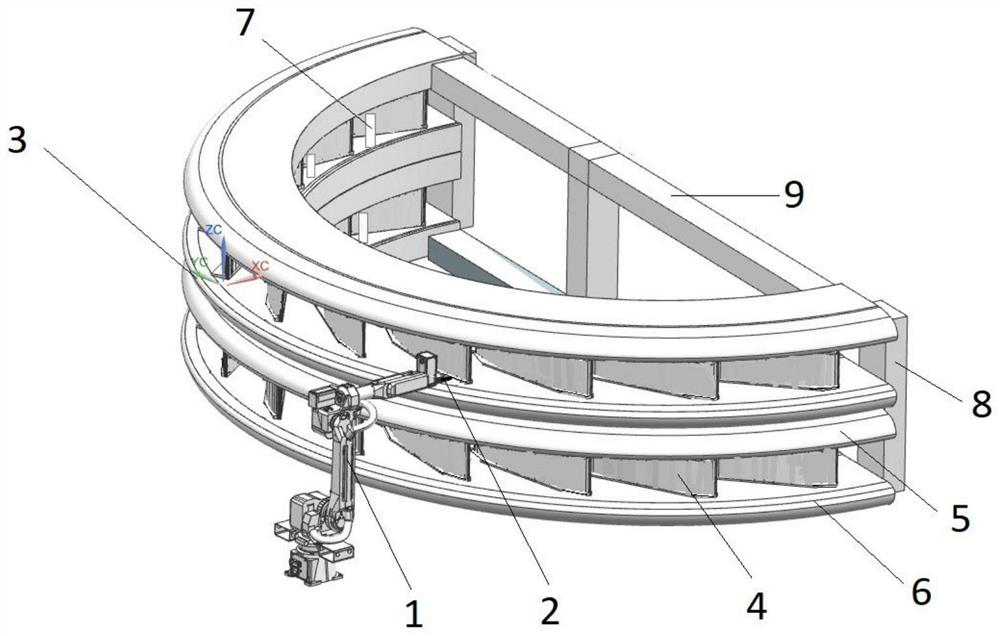

[0032] 1) Confirm welding accessibility: In ROBOGUIDE offline programming software, such as figure 1 As shown, the FANUC M-20iA welding robot 1 is used to clamp the L-shaped narrow gap gas shielded welding torch 2, the preset assembly method, assembly size, tension support position, seat ring 3 and welding robot 1 relative position, and the simulation robot is welded and fixed The narrow gap groove between the guide vane 4 and the upper ring plate 5 and the lower ring plate 6, to verify the accessibility of welding;

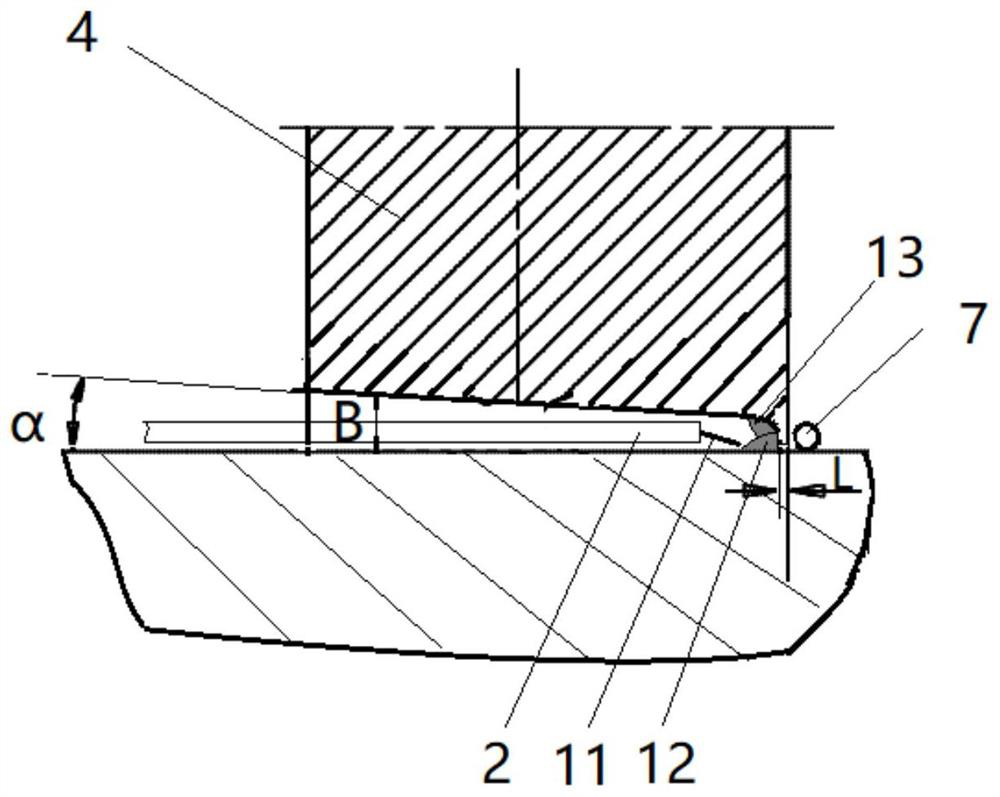

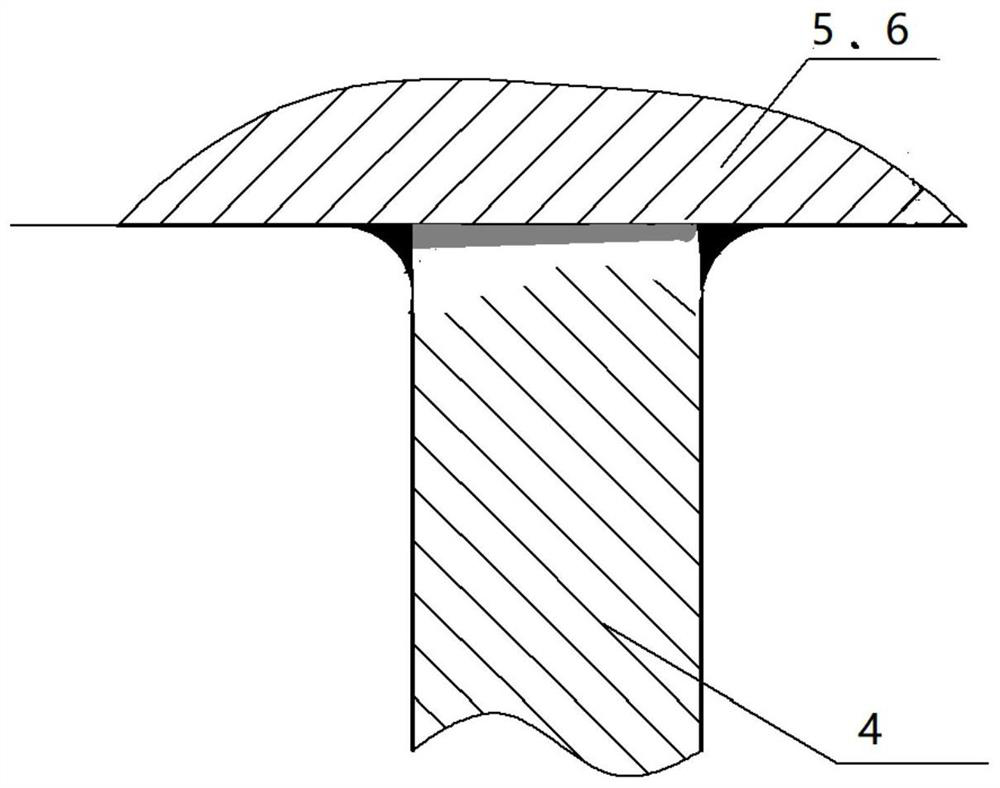

[0033] 2) Welding groove design and processing: such as figure 2 As shown, the grooves at both ends of the fixed guide vane 4 are designed as single-sided narrow gap grooves. 22mm; use a boring machine to process the groove according to the drawings;

[0034] 3) Assembly: The seat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com