A spiral plate heat exchanger and its welding method

A spiral plate type, heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc. The effect of reducing labor intensity, reducing the amount of weld fill, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

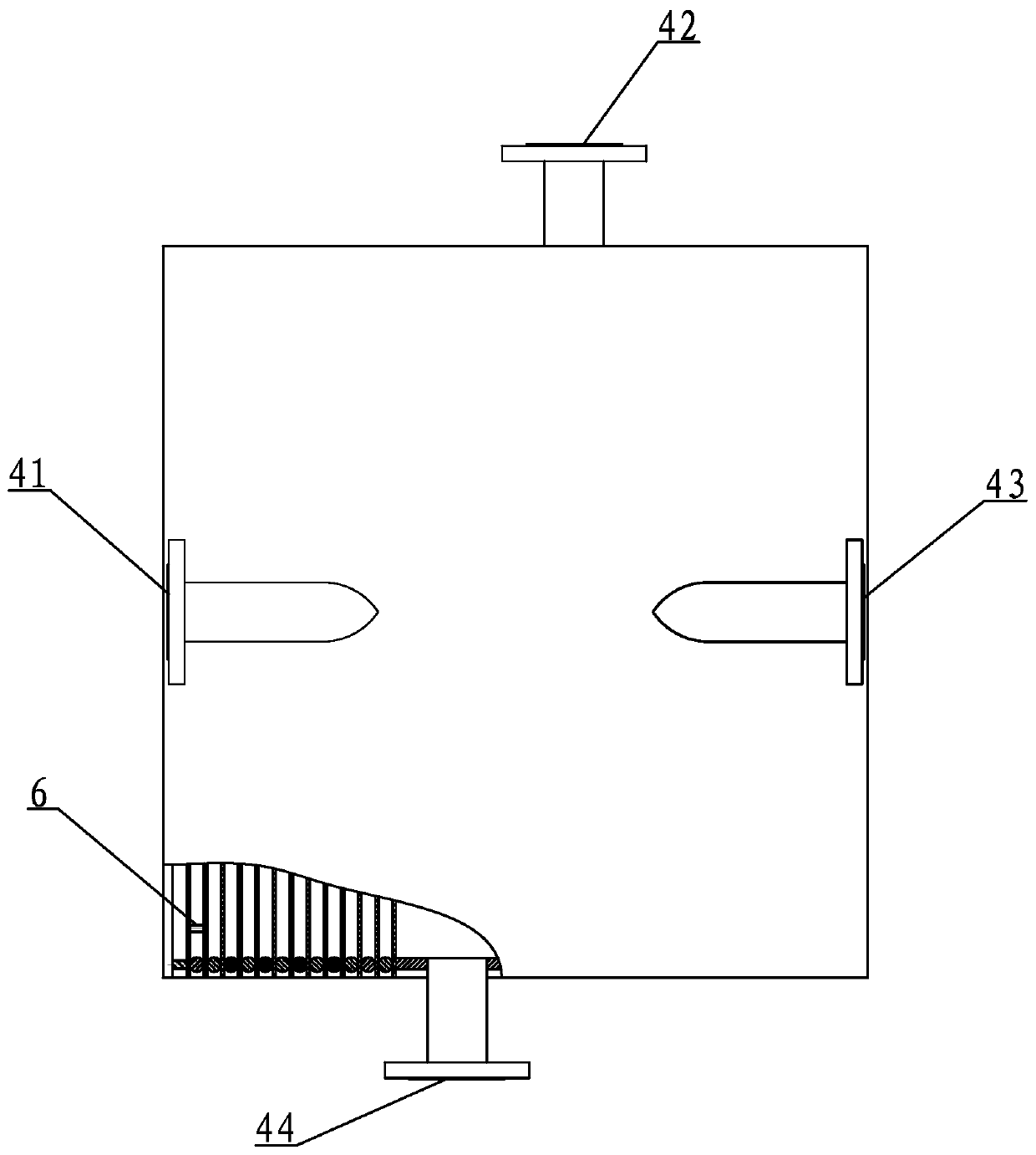

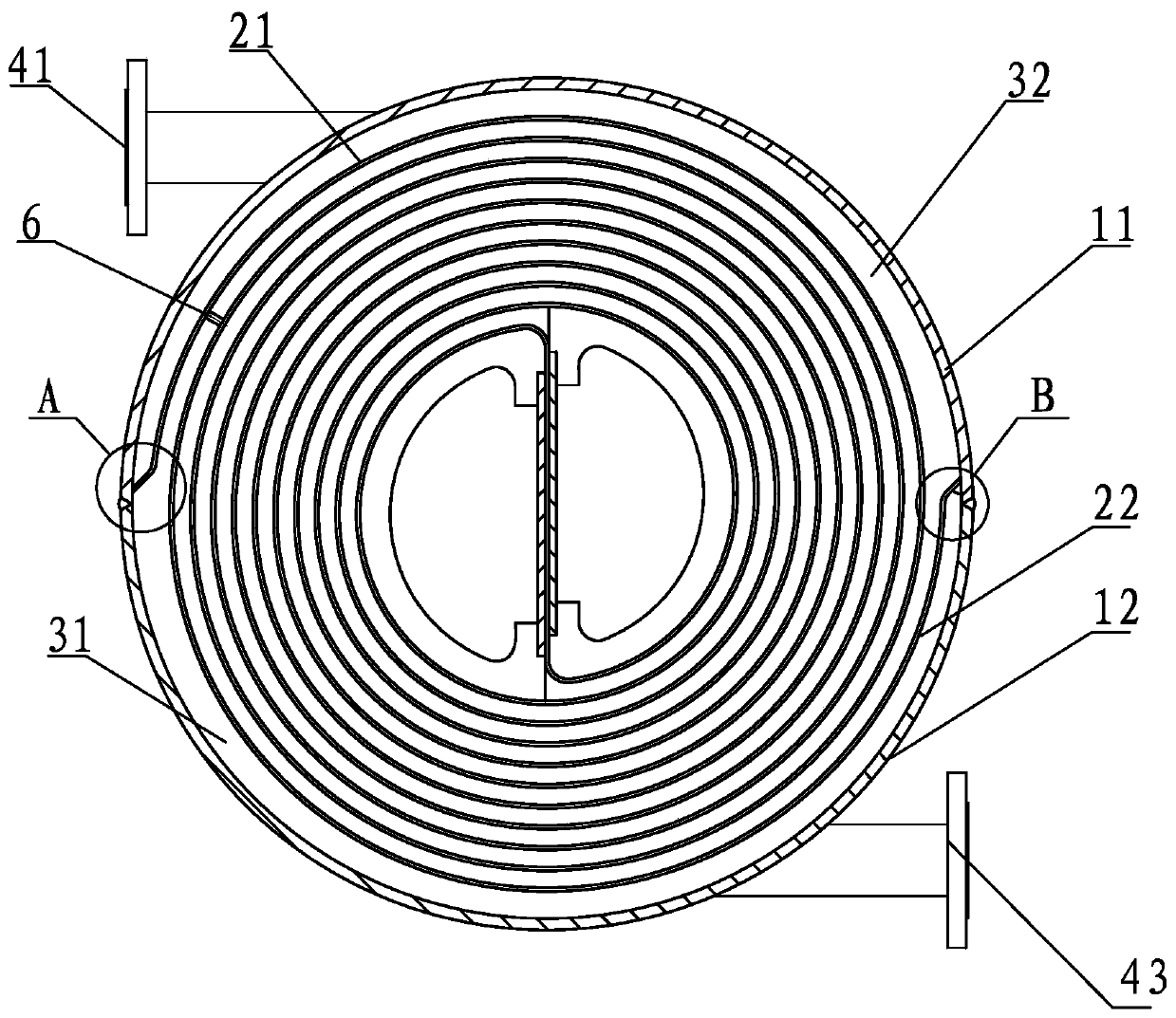

[0026] Embodiment one: see attached figure 1 As shown, a spiral plate heat exchanger includes a cylindrical shell and a heat exchange device arranged in the shell, and the heat exchange device includes first heat exchange plates 21 wound in a helical shape. and the second heat exchange plate 22, and a plurality of spacer columns 6 arranged between the first heat exchange plate 21 and the second heat exchange plate 22, and the housing includes two semicircles welded together barrel-shaped first shell 11 and second shell 12, the outer ends of the first heat exchange plate 21 and the second heat exchange plate 22 are respectively welded to the inner surface of the first shell 11 .

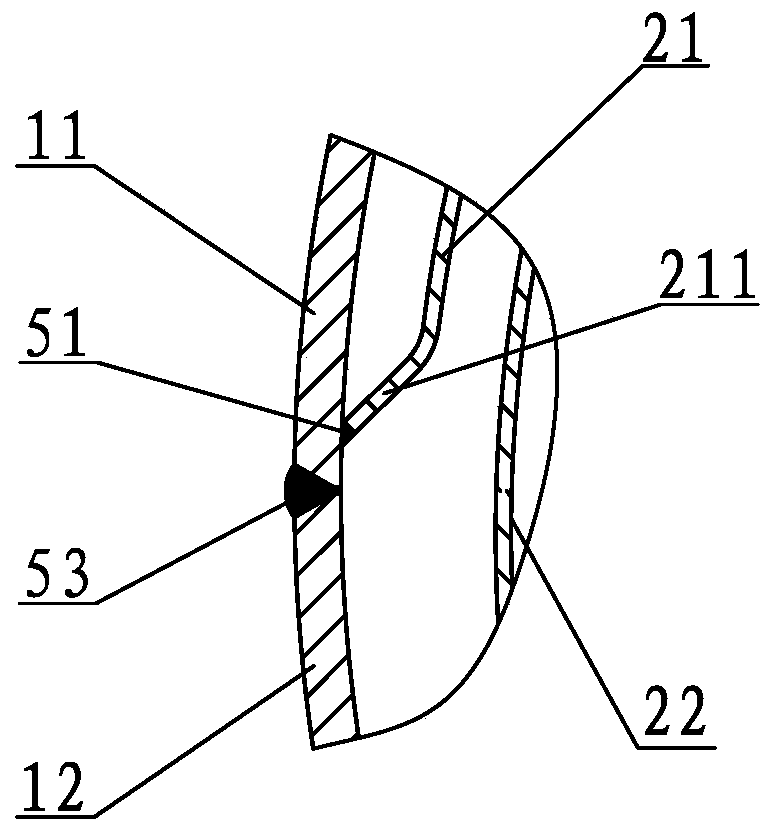

[0027] The first housing 11 includes an arc-shaped body 111 , two arc-shaped arc edge portions 112 located at both ends of the body 111 , and two straight straight edges located at opposite sides of the body 111 . The edge portion 113 , the welded edges of the outer ends of the first heat exchange ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com