A double-sided double-arc gas-shielded welding process for ultra-high-strength steel

A gas shielded welding and ultra-high strength steel technology, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of magnetic bias blowing and low welding efficiency, reduce the filling amount, improve welding quality, and improve welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

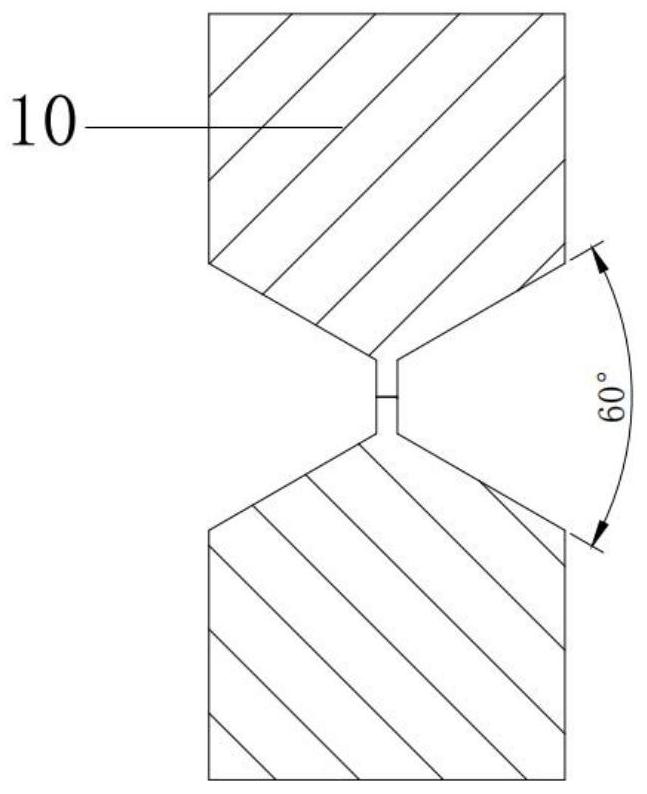

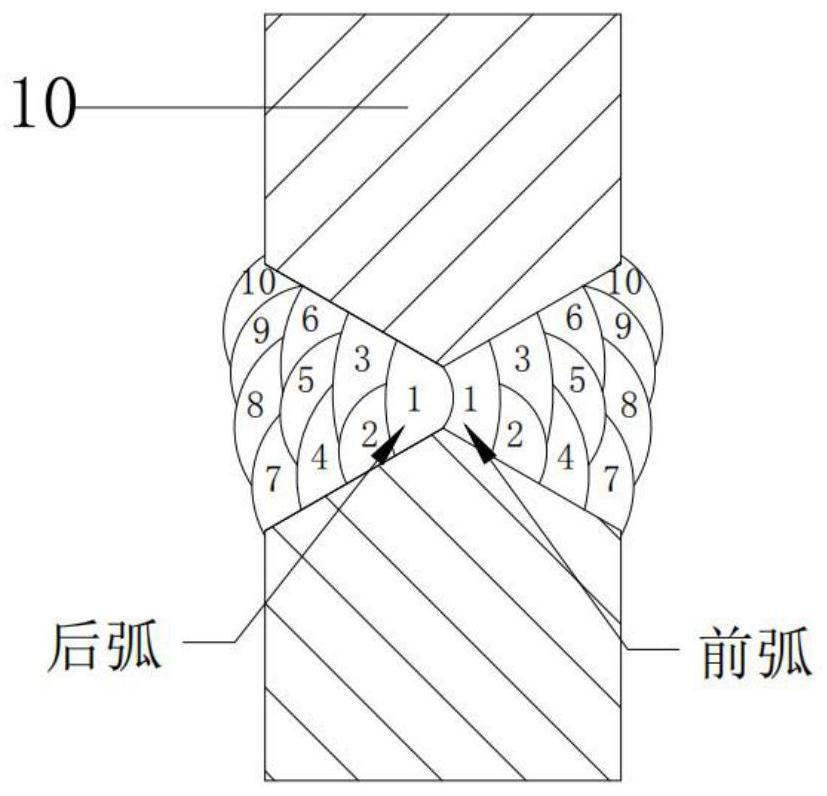

[0027] see figure 1 and figure 2 As shown, in Embodiment 1 of the present invention, the ultra-high-strength steel plate 10 with a thickness of 34 mm is welded by double-sided double-arc gas shielded welding, including the following steps:

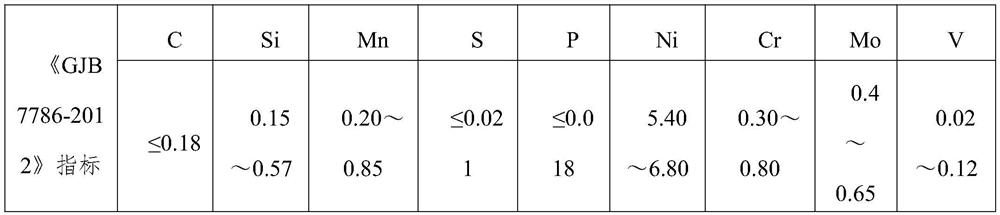

[0028] (1) Sampling re-inspection of the test steel plate and welding consumables. The re-inspection content includes chemical composition and mechanical properties. The re-inspection result of the steel plate must meet the requirements of "GJB 7786-2012", and the re-inspection result of the welding wire must meet the "JS80 welding wire supply acceptance "Technical Conditions", the chemical composition of ultra-high-strength steel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com