Expanded tube welding production method of simple evaporator

A production method and evaporator technology, applied in heat exchange equipment and other directions, can solve the problems of insufficient sealing of simple evaporators, and achieve the effects of ensuring sealing, improving yield, and simple and rigorous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

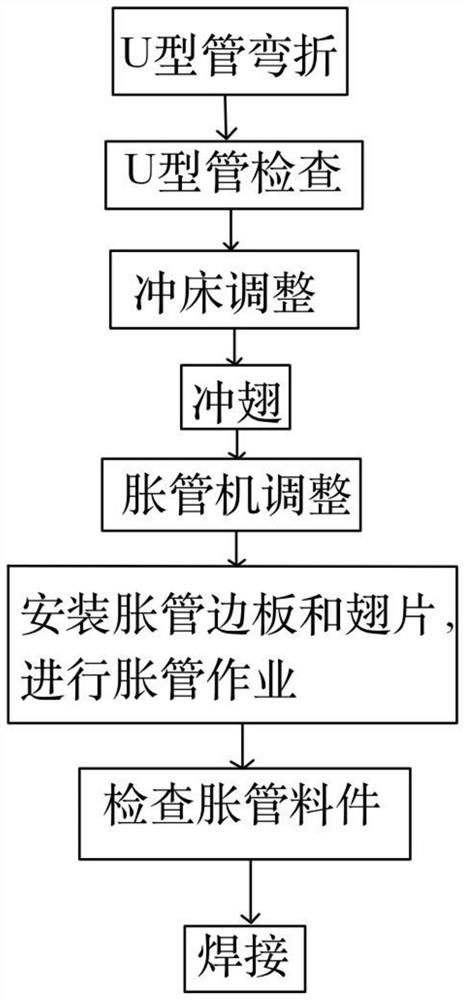

[0030] Refer to the technical process of the embodiment of the expansion tube welding production method of the simple evaporator of the present invention figure 1 As shown, it specifically includes the following steps:

[0031] S10, put the copper pipe material on the automatic pipe cutting and bending machine, pass through the material passage, and send it to the straightening system for straightening, install the straightened copper pipe that passed through the clamping feeder, and bend it Made into a U-shaped tube;

[0032] S20, check the bent U-shaped tube, and confirm that there is no pinch or bruise on the surface of the U-shaped tube, and there is no damage to the bottom of the U-shaped bend and the nozzle;

[0033] S30, installing the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com