Argon arc welding technological method for nickel base alloy tubes

A technology of nickel-based alloy and process method, applied in welding medium, welding equipment, metal processing, etc., can solve problems such as incomplete penetration, overheating of weld metal, and lack of fusion, and achieve excellent welding quality and beautiful weld shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The diameter of a ZG45Ni35Cr25NbM nickel-based alloy pipe centrifugally cast in a certain project is φ108×10.8mm. The specific implementation steps are as follows:

[0024] (1) The welding material is ERNiCr-3, the length is 1m, and the diameter of the welding wire is φ2.0mm; the welding wire is cleaned with acetone and dried; the protective gas is argon with a purity of ≥99.99%.

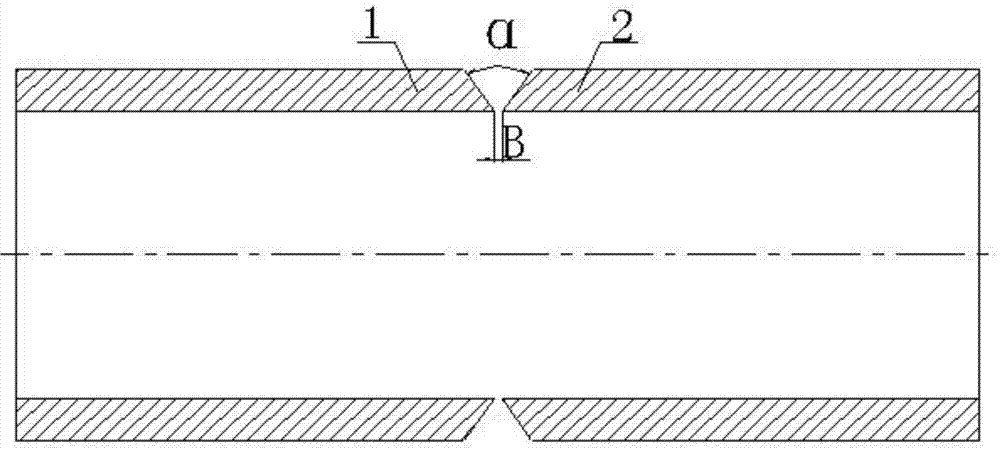

[0025] (2) if figure 1 As shown, the nickel-based alloy tube 1 and the nickel-based alloy tube 2 are machined into a V-shaped butt joint groove, and the angle of the groove is α is 65° without blunt edges. Clean the surface within the range to remove the hardened layer, burrs, etc. that affect the welding quality, and use acetone to clean the oil stains, various marks, and impurities around the groove and the groove.

[0026] (3) After cleaning the groove and its surroundings, use PT to test. If there is no crack on the surface, it is qualified. After passing the test, wash off the penetrati...

Embodiment 2

[0032] The centrifugal casting ZG45Ni35Cr25NbM nickel-based alloy pipe in a project has a diameter of φ141×18mm, which is a service pipe that has been used. The specific implementation steps are as follows:

[0033] (1) Selection of welding materials. According to the content of alloying elements in the quality certification document of the material, the straight welding wire ERNiCr-3 with a nickel content percentage greater than that of the base metal and relatively less harmful impurity elements such as S and P is selected. The length is 1m and the diameter of the welding wire is φ2.0mm. ; The welding wire is cleaned with acetone and dried; the protective gas is argon with a purity of ≥99.99%.

[0034] (2) if figure 1As shown, the nickel-based alloy tube 1 and the nickel-based alloy tube 2 are machined into a V-shaped butt joint groove, and the angle of the groove is α, which is 70° without blunt edges. Clean the surface within the range to remove the hardened layer and bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com