Rotary intelligent automatic welding workstation for five large pieces of passenger car body framework

An automatic welding and rotary technology, applied in the field of machinery, can solve the problems of low welding efficiency, poor consistency and poor welding quality, and achieve the effect of high welding efficiency, reducing operation difficulty and improving welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

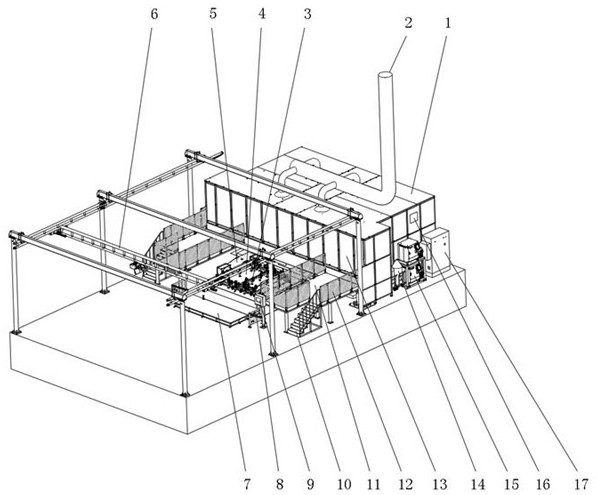

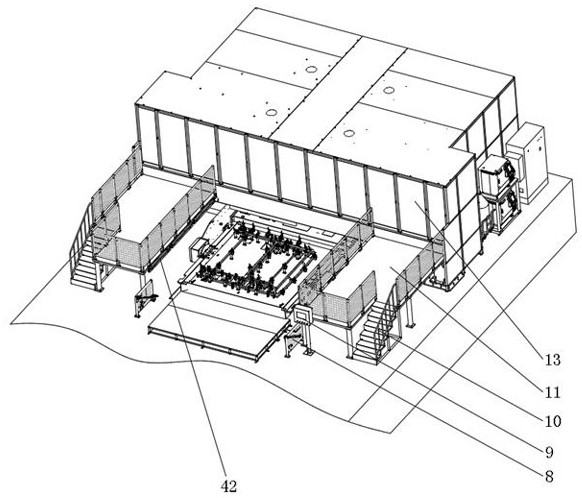

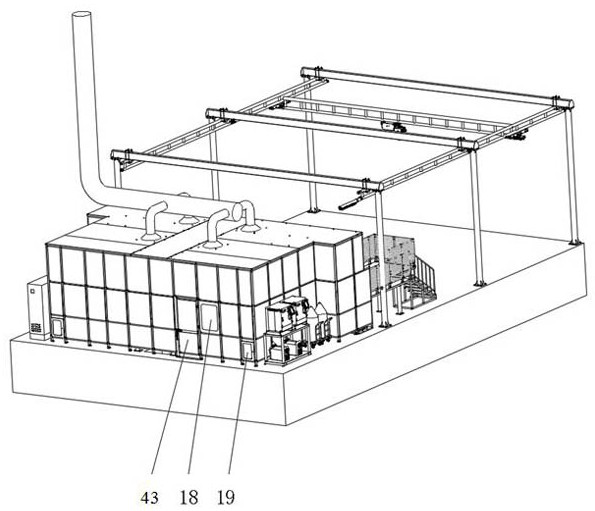

[0041] Such as Figure 1 to Figure 8 As shown, a rotary intelligent automatic welding workstation of the present invention for five large pieces of passenger car body frame includes a welding workshop 1 and a rotary positioner 5. The front of the welding workshop 1 is provided with a loading and unloading station 4. The welding workshop 1 is provided with a welding station 38, the first half of the rotary positioner 5 is set in front of the welding workshop 1, the second half of the rotary positioner 5 is set under the welding workshop 1, and the rotary positioner 5 The first half part is set as the first station 30, and the second half is set as the second station 34. The first station 30 and the second station 34 are respectively provided with welding tooling 3, and the lower side of the rotary positioner 5 is connected to There is a rotating main shaft 32, and the rotating main shaft 32 is connected to the driving device through a transmission mechanism. The rotary position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com