Large-diameter thick-wall steel pipe welding equipment

A welding equipment and large-diameter technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of repair difficulty and reduce repair difficulty, improve welding quality, reduce temperature rise speed and temperature rise Quantity, guaranteed performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

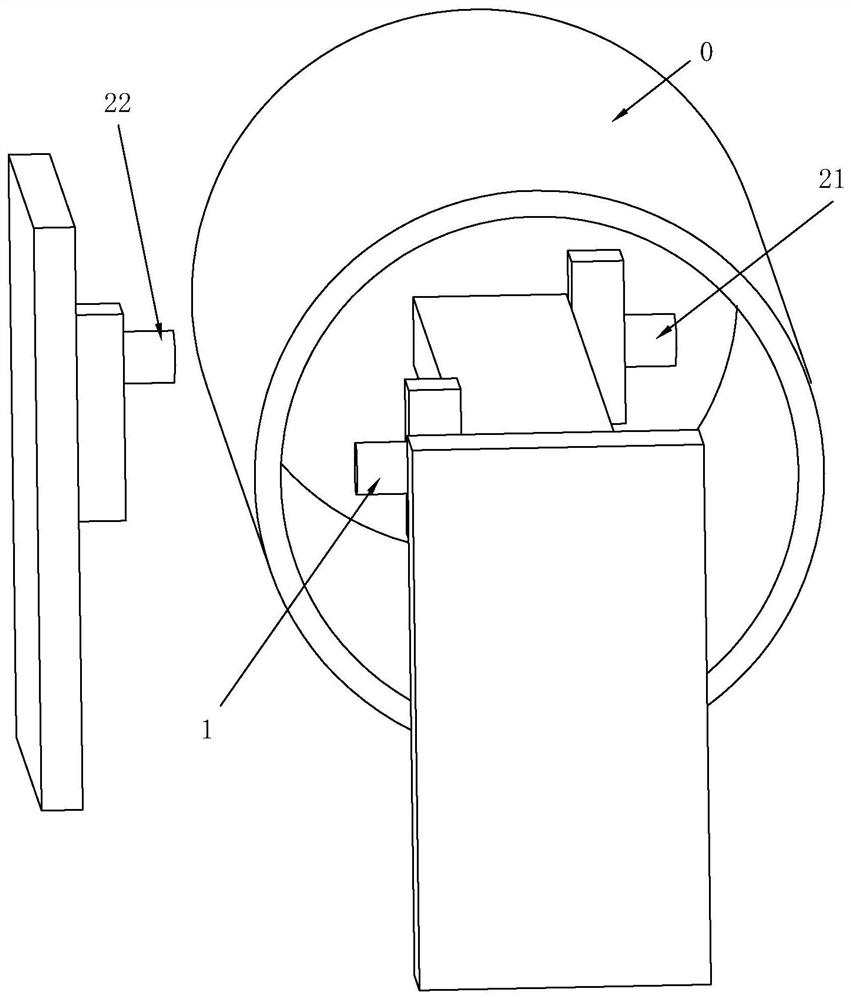

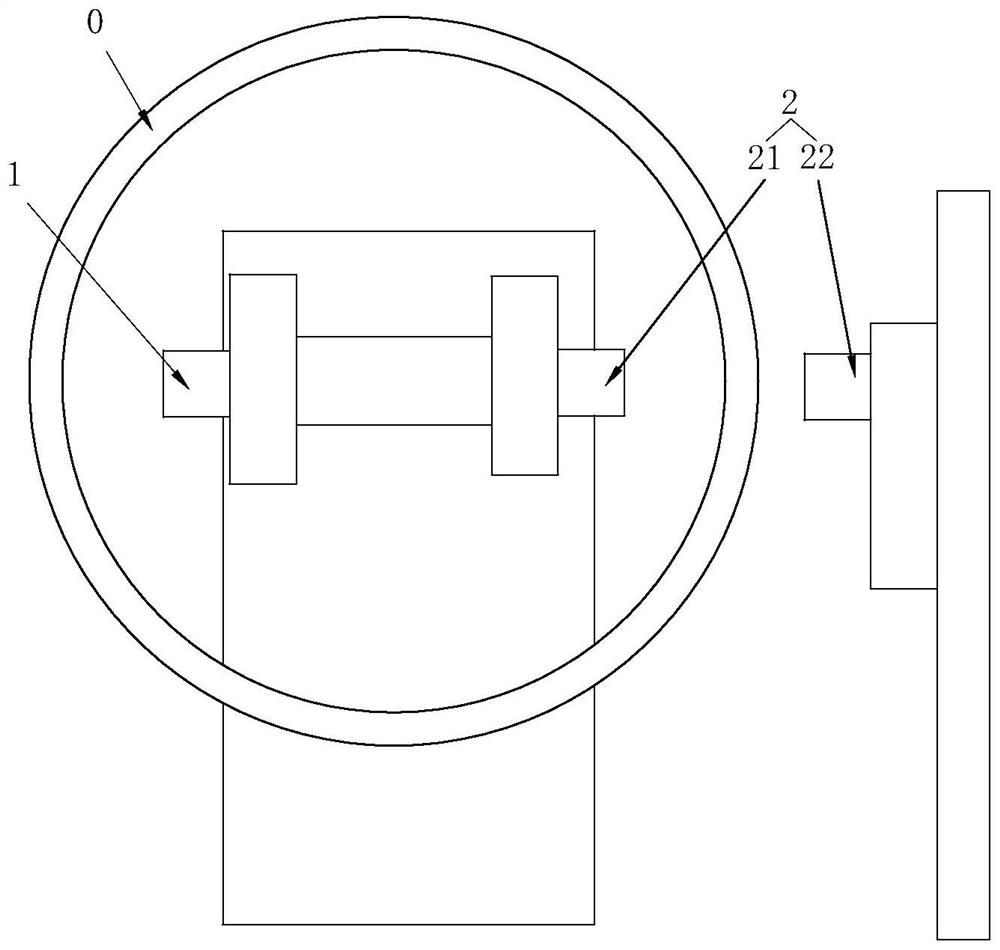

[0034] see figure 1 with figure 2 , a large-diameter thick-walled steel pipe welding equipment according to Embodiment 1 of the present invention, the welding equipment includes:

[0035] Positioning pre-welding device 1, the positioning pre-welding device 1 pre-welds the steel pipe;

[0036] Caliper measuring device, the diameter measuring device measures the diameter and ovality of the steel pipe;

[0037] A precision welding device 2, which performs performance welding on steel pipes;

[0038] Along the traveling direction of the steel pipe, the precise welding device 2 is located behind the positioning pre-welding device 1 .

[0039] As an improvement, the positioning pre-welding device 1 is located inside the steel pipe.

[0040] As an improvement, the precision welding device 2 is a five-wire welding device, in which three welding wires are outside and two welding wires are inside.

[0041] As an improvement, the positioning pre-welding device 1 and the precise wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com