Welding wire for laser butt welding of Al-Si coated plates formed by hot-stamping and butt welding method

A technology of hot stamping and laser tailor welding, applied in laser welding equipment, welding equipment, welding media, etc., can solve problems such as high cost, poor weld toughness, unfavorable weld seam or component fatigue performance and dynamic mechanical properties, etc. Achieve the effect of improving weld toughness and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

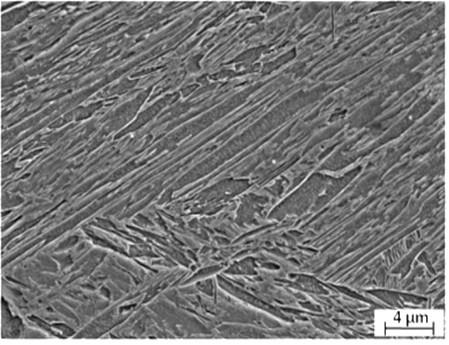

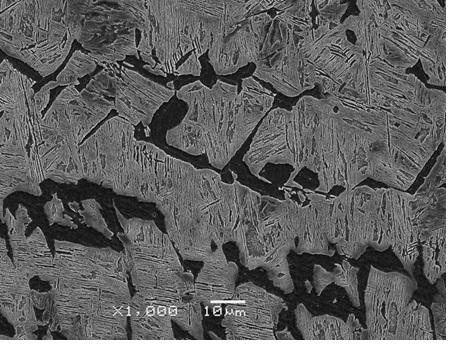

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with specific examples.

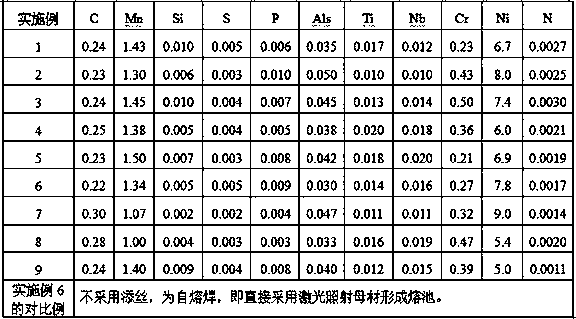

[0035] The chemical composition and mass percentage of the welding wire for laser tailor welding of hot stamping formed Al-Si coated plates in each embodiment of the present invention are: C≤0.30%, preferably 0.22-0.25%; Mn: 1.0-1.5%, preferably 1.3~1.5%; S≤0.005%; P≤0.010%; Als: 0.030~0.050%; Si≤0.010%; Ni: 5.0~9.0%, preferably 6.0~8.0%; Cr: 0.21~0.50%; Nb: 0.010 ~0.020%; Ti: 0.010~0.020%; N≤0.0030%, the balance is Fe and unavoidable impurities. The wire diameter d is 0.6-1.0mm.

[0036] Use above-mentioned welding wire to carry out the laser tailor welding method of hot stamping forming Al-Si coating plate and comprise the steps:

[0037] (1) Take two Al-Si coated plates after surface decontamination treatment: the thickness of the steel plate substrate in the Al-Si coated plate is 1.0-2.0mm, and its composition and mass percentage are: C: 0.21-0.25 %, Mn: 1.2~1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com